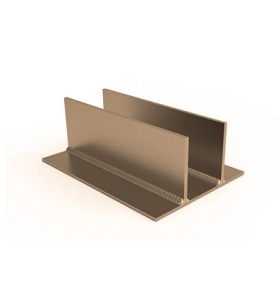

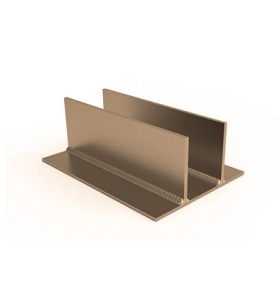

Mini Handheld Laser Welding Machine

The fiber handheld laser welding machine is easy to learn, simple and fast to set up and provides consistent high-quality results across a wide range of materials and thicknesses. This makes them suitable for both professionals and beginners. Mini fiber laser welding machines are designed to be lightweight and compact, making them easy to carry to different job sites or workshop. Its unique handheld operation allows for welding of workpieces at any angle and location. The operation of handheld laser welding equipment is very simple and does not require much experience from the welder. Compact design makes it easier to move in any workplace and only requires a small production space.

The laser beam of the laser source is transmitted through the fiber optic cable to the handheld welding gun and focused onto the surface of the welding material. After being absorbed by the substrate, it is converted into heat energy to melt the material or welding wire to achieve the effect of melting. With the assistance of inert gas protection, a high-quality weld seam is formed, which firmly welds the two objects together. The flow of cold water from the chiller cools and maintains a constant temperature for the laser cutter and the handheld welding head, playing a protective role for important components.

This portable handheld laser welder series has the advantages of high electro-optical conversion efficiency, high output power, excellent beam quality, compact structure, maintenance-free operation, and low cost.

Features of Compact Laser Welding Machine:

- Fast speed, high depth, and minimal deformation.

- The compact laser welding machine has a simple and user-friendly design, making it easy to operate. Built-in factory presets for all materials and thicknesses.

- Welding speed is 2~5 times faster than traditional welding(Argon arc welding, arc welding, gas welding, soldering and brazing etc.)

- High-speed welding across a wide range of materials and thicknesses, thick, thin, reflective and dissimilar metal welding without wire.

- It can weld difficult-to-melt materials such as titanium and quartz, as well as different materials with good results.

- Perform micro welding. The laser beam is focused to obtain a small spot, and can be accurately positioned, making it suitable for small parts produced in automated mass production.

- Operations are simple and can be learned by workers with 2 hours of training.

- The equipment has a long service life of up to 100,000 hours.

Advanced Laser Source

User-friendly and efficient, achieving faster and more precise results than TIG/MIG welding!

Digital Control System

Adjust welding parameters with ease, and switch between multiple welding modes at will! From precise spot welding to continuous welding, ensure you get the best results and quality every time you weld. The operation screen has a user-friendly touchscreen. It enables quick startup for users at any skill level.

New Design Laser Weld Gun/Humanized Design

Our hadheld laser welding gun is lightweight, ergonomic design weighs just 0.8kg. It’s built for comfort during long hours of work.

Wire Feeder Optional

If two weld metal gap more than 0.2mm that need filler wire.

HandHeld Laser Welding Mode

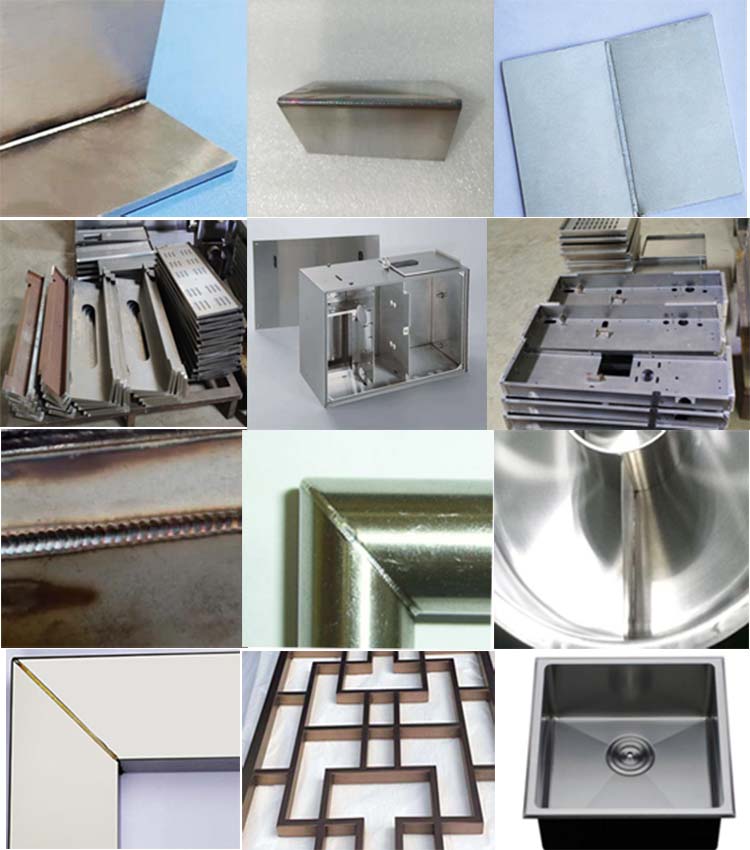

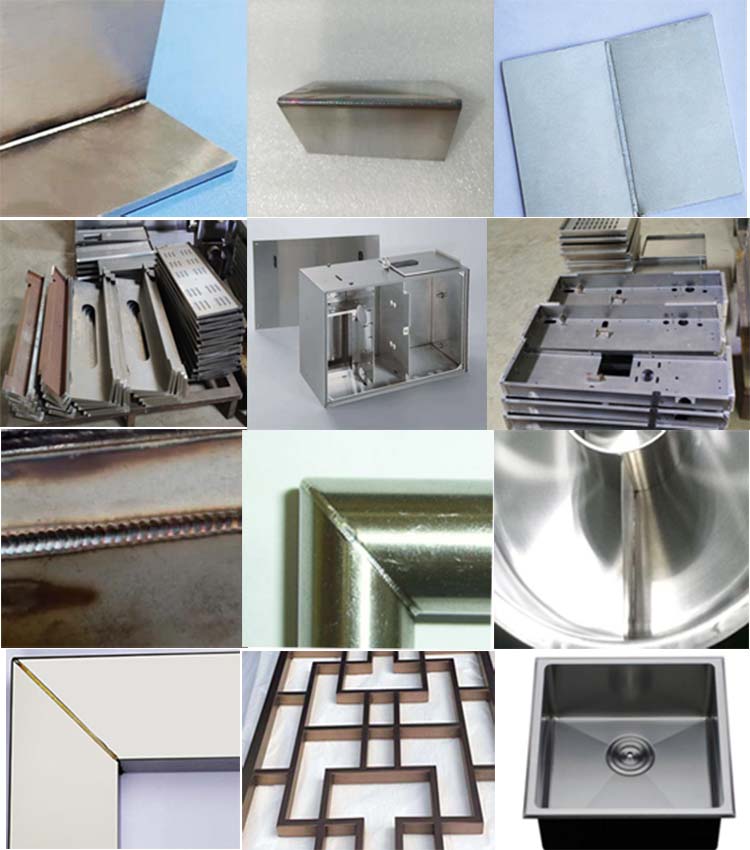

Various Metal Materials

|   |   |   |

| laser welding aluminum | laser welding carbon steel | laser welding stainless steel | laser welding copper |

Why Choose DPLASER Laser Service?

- Core Technology: We are both a manufacturer and seller of laser equipment, and can provide customized laser devices.

- Independent R&D: We can provide customized laser machines for any application of our customers, and develop new machines based on market research.

- Customer Support: We provide free technical support for equipment installation and use to help customers succeed.

- Strict Testing: All our suppliers are from world’s top manufacturers. Before delivery, each machine must undergo strict testing and inspections to ensure the quality and safety of the laser equipment.

- On-time Delivery: Each machine has an accurate assembly process and strict time control to ensure that customers receive goods promptly.

- After-Sales Service and Guarantee: We provide lifelong service for machines and accessories, and we are responsible for solving any problems that may arise during this period.

Application industries:

Metal manufacturing and processing industries, such as metal welding, surface welding of electrical switch cabinets, elevator manufacturing, household appliance manufacturing, stainless steel stove, frame, doors and windows, fence, electric box, pipeline, and kitchenware manufacturing. Welding of various metal materials such as carbon steel, aluminum alloy plate, galvanized plate, electrolytic plate, silicon steel, titanium alloy, galvanized aluminum plate, and copper.

Reviews

There are no reviews yet.