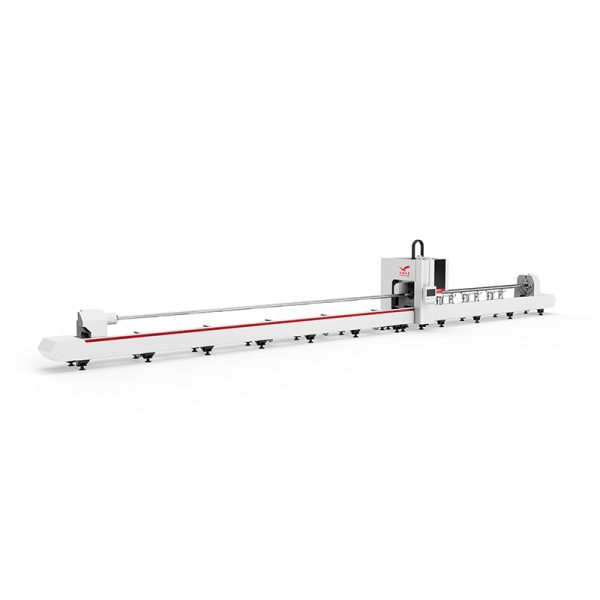

CNC Laser Cutting Machine for Metal

Boosting Metal Cutting and Processing Productivity by 85%

CNC metal laser cutting systems are widely employed in various industries, including automotive parts manufacturing, electronics, metal products, instrument manufacturing, construction materials, and more. They are capable of cutting a wide range of metal materials, such as stainless steel, aluminum, zinc, copper, and carbon steel sheets.

Industrial laser cutting machines offer high-speed and high-precision cutting of diverse metals, making them the top choice for enterprises seeking enhanced production capacity. Businesses can now utilize metal laser cutting machine to achieve higher output rates and optimization the manufacturing process, ultimately leading to increased profitability.

Metal Processing

Engraving

Laser engraving nachine is a precise metalworking method that uses a high-energy laser beam to etch patterns, text, or designs onto the surface of metal. This process is extremely accurate and can create very detailed markings, making it suitable for creating personalized labels, decorative parts, and industrial components.

Cutting

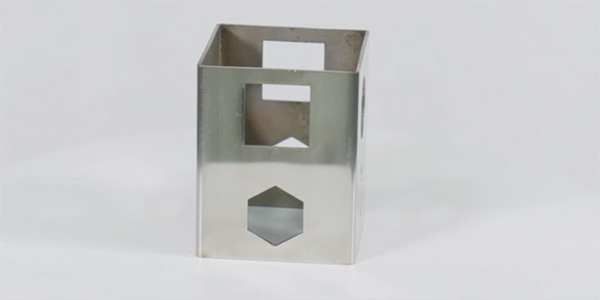

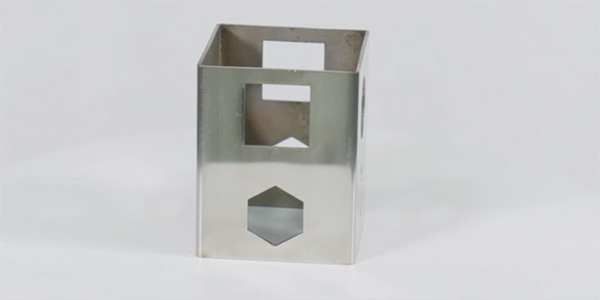

Laser cutter employs a powerful laser beam to precisely cut metal sheets and tubes into the desired shapes and sizes. Laser cutting machines can achieve high cutting speeds and excellent precision while maintaining narrow cuts and a clean finish. This technology is widely used in manufacturing to cut various metal sheets, tubes, and metal components.

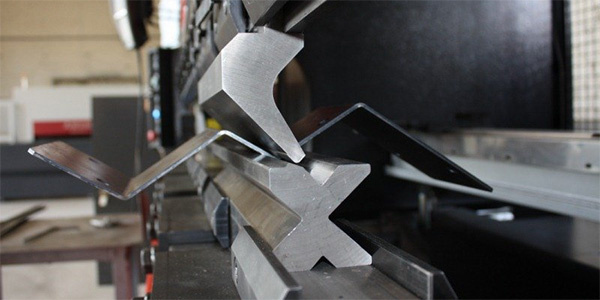

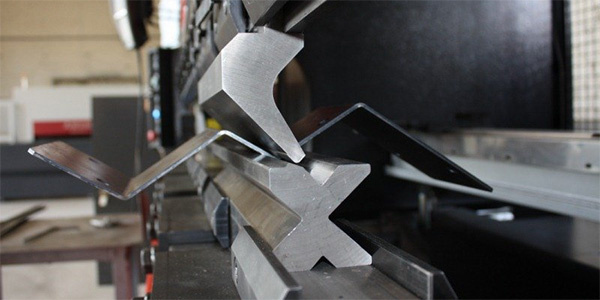

Bending

Sheet metal bending machine is a process of shaping metal sheets into the desired form. Typically, metal bending machines are used to bend metal sheets into specific angles and curves. Sheet metal bending brake is crucial in the manufacturing of metal enclosures, chassis, and casings because it can achieve precise shapes and bending angles, ensuring a perfect fit and functionality of components.

Industrial laser equipment provides highly precise and customized solutions for various metal processing needs, driving the development and innovation of modern manufacturing industries.

The Benefits of Laser Cutting Metal

Fiber laser cutting system offers fast cutting speeds, high precision, and excellent beam efficiency, making it suitable for a wide range of metal sheet manufacturing applications. It provides narrow cuts, superior cutting quality, minimal distortion, and reduced heat-affected zones. With the upgrading of CNC and laser technology, it’s not limited to flat cutting but gradually extends its cutting capabilities to three-dimensional tasks.

Laser cutting machine for metal offers a combination of precision, speed, and versatility, making it an excellent choice for a wide range of applications across different industries, including kitchenware, home appliance boxes, automobile manufacturing, sheet metal processing, plastic products, fabrics, billboards, mechanical parts, handicrafts, decorations, etc.

CNC laser cutting machine provides an exceptionally high level of precision. It can create intricate and fine details with minimal material waste, making it ideal for applications that demand accuracy.

Laser can rapidly cut through metal, reducing production time and increasing efficiency. The ability to cut a 40 mm steel sheet using a 12 kW laser provides speeds some 10x faster than a traditional processing. Few production methods can come close in processing speed to laser cutting.

Laser cutting is suitable for a wide range of metals, including stainless steel, iron, carbon steel, aluminum, copper, mild steel, titanium and tungsten. This versatility makes it a valuable tool for various metalworking in many manufacturing industries.

Laser cutting leaves behind clean and smooth edges, eliminating the need for secondary finishing processes. This results in cost savings and shorter lead times.

Laser cutting is an eco-friendly option, as it produces minimal waste, reduces energy consumption, and eliminates the need for harmful chemicals or coolants.

Laser cutting can effortlessly handle complex shapes and intricate designs, making it perfect for customized or unique projects. No need mold making, saving production costs and improving efficiency.

While initial setup costs can be high, the long-term cost-effectiveness of laser cutting is realized through reduced material waste, labor costs, and increased production rates.

Providing your samples and free proofing

- Metal Sheet & Tube Laser Cutting Machine

CNC Fiber Laser Cutting Machine for Plate & Pipe

Add to Cart

Fiber Laser Cutting MachineThickness & Power

| Power | 500W | 1000W | 2000W | 3000W | 4000W | 6000W | |

| Material | Thickness(mm) | Speed(m/min) | Speed(m/min) | Speed(m/min) | Speed(m/min) | Speed(m/min) | Speed(m/min) |

| Carbon steel(Q235A) | 1 | 8-13 | 15-24 | 24-30 | 30-42 | 40-55 | 60-80 |

| 2 | 3-4.5 | 5-7.5 | 5.5-8 | 7-9 | 8-10 | 9-12 | |

| 3 | 1.8-3 | 2.4-4 | 3.5-4.8 | 4-6.5 | 4.5-6.5 | 4-7 | |

| 4 | 1.3-1.5 | 2-2.4 | 2.8-3.5 | 3.5-4.5 | 4-5 | 4.2-5.5 | |

| 5 | 0.9-1.1 | 1.8-2 | 2.5-3 | 3.-3.5 | 3-4.2 | 3.5-4.2 | |

| 6 | 0.6-0.9 | 1.4-1.6 | 1.8-2.6 | 2.5-3.2 | 3-3.5 | 3-4 | |

| 8 | 0.8-1.2 | 1.2-18 | 1.8-2.6 | 2-3 | 2.2-3.2 | ||

| 10 | 0.6-1 | 1.1-1.3 | 1.4-2 | 1.5-2.5 | 1.8-2.5 | ||

| 12 | 0.5-0.8 | 0.9-1.2 | 1.2-1.6 | 1.4-2 | 1.6-2 | ||

| 14 | 0.7-0.8 | 0.9-1.4 | 1-1.6 | 1.5-1.8 | |||

| 16 | 0.6-0.7 | 0.8-1.2 | 0.8-1.2 | 0.8-1.5 | |||

| 18 | 0.4-0.6 | 0.7-1 | 0.8-1.1 | 0.9-1.2 | |||

| 20 | 0.6-0.8 | 0.7-1 | 0.8-1.1 | ||||

| 22 | 0.4-0.6 | 0.6-0.8 | 0.7-0.9 | ||||

| 25 | 0.3-0.5 | 0.4-0.6 | |||||

| Stainless steel(201) | 1 | 8-13 | 18-25 | 24-30 | 30-42 | 40-55 | 60- 80 |

| 2 | 2.4-5 | 7-12 | 10-17 | 18-21 | 20-30 | 30-42 | |

| 3 | 0.6-0.8 | 1.8-2.5 | 4-6.5 | 8-12 | 12- 18 | 18-24 | |

| 4 | 1.2-1.3 | 3-4.5 | 6-9 | 8-12 | 10-18 | ||

| 5 | 0.6-0.7 | 1.8-2.5 | 3-5 | 4-6.5 | 8-12 | ||

| 6 | 1.2-2 | 3-4.3 | 4-6.5 | 6-9 | |||

| 8 | 0.7-1 | 1.5-2 | 1.8-3 | 4-5 | |||

| 10 | 0.8-1 | 0.8-1.5 | 1.8-2.5 | ||||

| 12 | 0.5-0.8 | 0.6-1 | 1.2-1.8 | ||||

| 14 | 0.5-0.8 | 0.6-0.8 | |||||

| 20 | 0.4-0.5 | 0.5-0.8 | |||||

| 25 | 0.4-0.5 | ||||||

| Aluminum | 1 | 4-5.5 | 6-10 | 20-25 | 25-40 | 40-55 | 55-65 |

| 2 | 0.7-1.5 | 2.8-3.6 | 7-10 | 10-18 | 15-25 | 25-35 | |

| 3 | 0.7-1.5 | 4-6 | 7-10 | 10-15 | 13- 18 | ||

| 4 | 2-3 | 4-5.5 | 8-10 | 10-12 | |||

| 5 | 1.2-1.8 | 3-4 | 5-7 | 6-10 | |||

| 6 | 0.7-1 | 1.5-2.5 | 3.5-4 | 4-6 | |||

| 8 | 0.7-1 | 1.5-2 | 2-3 | ||||

| 10 | 0.5-0.7 | 1-1.5 | 1.5-2.1 | ||||

| 12 | 0.7-0.9 | 0.8-1.4 | |||||

| 16 | 0.5-0.7 | 0.7-1 | |||||

| 20 | 0.5-0.7 | ||||||

| Brass | 1 | 4-5.5 | 6-10 | 14-16 | 25-35 | 35-45 | 50-60 |

| 2 | 0.5-1 | 2.8-3.6 | 4.5-6.5 | 10-15 | 10-15 | 25-30 | |

| 3 | 0.5-1 | 2.5-3.5 | 5-8 | 7-10 | 12-18 | ||

| 4 | 1.5-2 | 3.5-5 | 5-8 | 8-10 | |||

| 5 | 1.4-1.6 | 2.5-3.2 | 3.5-5 | 6-7 | |||

| 6 | 1.2-2 | 1.5-2.5 | 3.5-4.5 | ||||

| 8 | 0.7-0.9 | 0.8-1.5 | 1.6-2.2 | ||||

| 10 | 0.5-0.8 | 0.8-1.4 | |||||

| 12 | 0.6-0.8 |

*Please consult our experts for more material and power parameters.

Get a Free Laser Cutting Machine Quote!

Do you have a question for us? Are you looking for career advice on laser machines? Contact us if you have a query about the laser equiment and laser industry.