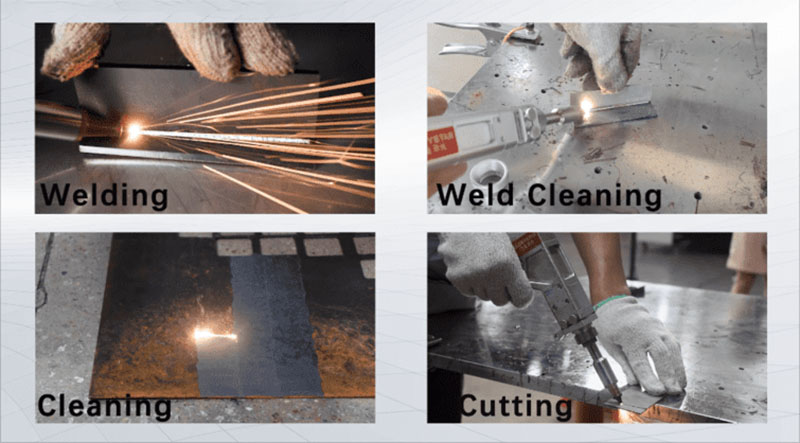

The all-in-one laser welding machine not only offers welding capabilities but also integrates cutting and cleaning functions, providing a comprehensive processing solution. Using high-energy laser beams, the machine can precisely weld a variety of metal and non-metal materials, offering advantages such as fast welding speeds, fine seams, and minimal heat-affected zones. Using a laser welder for cutting metal ensures efficient and precise cutting of materials, meeting diverse application needs. The all-in-one design saves space, boosts production efficiency, and has become an indispensable, ideal multifunctional tool in modern manufacturing.

4 in 1 Laser Welder Cutter Cleaner

Laser Welding

The main function of laser welding is to precisely connect materials using a high-power laser beam, providing efficient and high-quality welding results. It is suitable for the precise welding needs of various metals and alloys.

Laser Cleaning

In addition to welding, this device also features a laser cleaning function. Through high-energy laser beams, it can effectively remove rust, contaminants, or other unwanted substances from the workpiece surface before or after welding, ensuring a clean, smooth surface and improving welding quality.

Laser Cutting

This all in one laser welding and cutting machine also allows for high-precision laser cutting, suitable for cutting a variety of materials. It is a multifunctional device that integrates both welding and cutting, making it ideal for complex applications requiring both welding and cutting.

Weld Seam Cleaning

After welding, the device can clean the weld seam, ensuring the surface is bright and tidy. This prevents impurities from the welding process from affecting the appearance and quality, ensuring the final weld seam achieves the best visual effect and performance standards.

Can a Laser Welding Machine Cut Metal?

Yes, all in one handheld laser welding machine can cut metal materials, but its cutting capabilities are somewhat limited. Since handheld laser welding machines typically use lower-power lasers, they are more suitable for cutting thinner metal materials, such as steel, aluminum and copper plates. The cutting thickness is usually within 3mm.

The cutting thickness can be influenced by factors such as the type of gas used, gas pressure, and nozzle shape. Typically, when using oxygen, the cutting speed is faster, making it suitable for cutting thicker materials like carbon steel and alloy steel. On the other hand, using nitrogen results in slower cutting speeds, which is better for cutting thinner materials like copper and stainless steel.

All-in-one Welding and Cutting Heads of Laser Welder

What’s the difference between the laser welding head and the laser cutting head? In fact, these two functions are entirely different. The laser welding machine is used for welding metals, while the laser cutting machine is used for cutting processes.

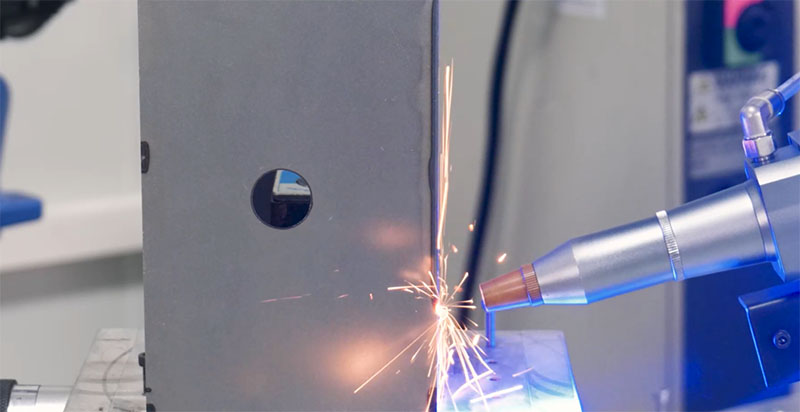

Laser Welding Head

The laser welding head is a key component of the laser welding machine, widely used in welding thin-walled materials and precision parts. It can perform various types of welding, such as spot welding, butt welding, overlap welding, and sealing welding, with a high depth-to-width ratio.

Compared to traditional welding methods, laser welding offers advantages like a smaller weld width, smaller heat-affected zone, less distortion, and faster welding speed. The weld seams are smooth and aesthetically pleasing, usually requiring no post-processing or only minimal finishing. Weld quality is high, with no porosity, and precise control is possible. The small laser spot and high positioning accuracy make it especially suitable for automated production. The laser welding machine heats a localized area of the material with high-energy laser pulses, and the laser energy spreads into the material through thermal conduction, causing it to melt and form a specific molten pool, thus achieving high-quality welding.

Laser Cutting Head

The laser cutting head is the core component of the all in one laser welding gun, using a high-power laser beam to precisely heat the workpiece. When the laser beam focuses on the material surface, the material is rapidly heated to its melting point, and some of it is vaporized or melted under the high temperature of the laser. During the cutting process, the laser beam is combined with a gas (such as oxygen, nitrogen, or air), which helps to blow away the molten or vaporized material, forming a cut seam.

Unlike welding, laser cutting relies not only on heat conduction but also on the high-speed flow of gas to remove the molten metal, ensuring a clean and tidy cut. By adjusting the laser power, cutting speed, and gas pressure, efficient cutting of different materials and thicknesses can be achieved.

After cutting, the material edges are usually smooth and precise, with no burrs, reducing the need for post-processing and improving production efficiency and product quality. The handheld design further enhances operational flexibility, allowing for cutting of different shapes and complex workpieces.

How does the All in One Handheld Laser Welder achieve Integrated Functions?

Metal Laser Welding Cleaning Cutting Machine Functions

All-in-One Control System: The new handheld laser welder is equipped with an industrial-grade LED touch screen and an intelligent operating system, simplifying the operation process. Users can quickly select the appropriate process mode by choosing from preset process parameters. Even beginners can master the operation in a short time, producing high-quality, consistent welds, which effectively reduces labor costs and improves production efficiency.

Nozzle Variety: The laser welding gun supports multiple nozzle configurations, including cutting nozzles and cleaning nozzles, making it adaptable to different product welding and material processing needs. This provides greater flexibility for various applications.

This combination of intelligent control and versatile nozzles makes the all-in-one laser welder a highly flexible and efficient tool, capable of handling multiple tasks like welding, cutting, cleaning, and more with ease.

How to Cut With a Laser Welding Machine?

Step 1: Choose the Right Nozzle

To use the cutting function of a handheld laser welding machine, you must replace the welding copper nozzle with a cutting copper nozzle. These machines typically come with welding nozzles for welding operations, but to activate the cutting function, the nozzle needs to be switched to a cutting nozzle. This simple step allows users to seamlessly switch between welding and cutting operations based on their needs.

Step 2: Configure Laser Cutting Parameters

The parameters required for laser cutting on an all in one laser welding machine are different from those for welding.

- Scan Speed: This parameter can be set freely according to the material and requirements.

- Scan Width: Set this to zero to ensure that the red light focuses on a single point.

- Peak Power: It is recommended to use the maximum power for cutting. Adjust this based on the specific material thickness.

- Duty Cycle: A 100% duty cycle is recommended for optimal performance.

- Frequency: Set this to a reference value of 1000.

Step 3: Secure the Workpiece

Before starting the cutting process, it is important to securely fix the workpiece in place. This ensures that the material doesn’t shift during cutting, which could lead to uneven results or damage. You can use clamps, magnetic fixtures, or a dedicated fixture table to keep the material stable and aligned with the laser beam. Make sure the workpiece is flat and positioned properly under the laser head.

Step 4: Keep the Red Light Center

The position indicated by the red dot is where the laser will make contact. It’s crucial to ensure that the red dot is centered properly. If the red dot is off-center, the laser could hit the copper nozzle directly, causing it to overheat and potentially get damaged.

Step 5: Begin Cutting with the Laser Welder

- Focus Requirement: Proper focus is essential for clean cutting. Ensure the focus is correctly set according to the material and thickness.

- Gas Requirements: Nitrogen is typically used for cleaner, brighter cut surfaces. To cut thicker materials, oxygen or air can be used, resulting in a darker cut surface.

- Avoid using argon as it may lead to poor cutting results.

- Cutting Thickness: For best results, the material thickness should be less than 3mm.

- Cutting Speed: Maintain a consistent hand speed during cutting to achieve even cuts.

This step-by-step guide helps ensure that you get the best cutting results from your laser welding machine!

Before starting to use a laser welding machine to cut metals, taking personal protective measures is crucial. This includes wearing safety goggles, gloves, and other necessary protective equipment to ensure safety when operating the handheld laser welder. Additionally, never touch the material after cutting, as it may still be very hot and could cause burns.

Benefits of Laser Welding Machines for Cutting Metals

Precision Cutting

Handheld laser welders offer unmatched cutting precision, allowing for accurate cuts on stainless steel, reducing material waste, and ensuring high-quality cuts. This prevents any deviations that could affect the integrity of the final product.

Versatility

Laser welders and cutting machines are suitable for various thicknesses of stainless steel, efficiently and consistently cutting thin metal sheets and pipes, meeting a wide range of application needs.

Portability and Flexibility

Unlike large cutting machines, handheld laser welders are compact and portable, enabling operators to cut in hard-to-reach areas. This makes them especially useful for on-site work and applications requiring high flexibility.

Speed and Efficiency

Compared to traditional cutting methods, handheld laser welders offer much higher cutting speeds, rapidly melting and vaporizing the metal. The increased speed translates to higher productivity and cost savings in industrial applications.

Minimal Heat Affected Zone (HAZ)

The highly focused laser beam ensures a minimal heat-affected zone, preventing excessive heat diffusion. This reduces material deformation or warping, maintaining the structural integrity of the cut material.

Wide Range of Material Thicknesses

Handheld laser welders can effectively cut a wide range of material thicknesses, providing excellent flexibility for various industrial and commercial cutting needs.

This article focuses on how to use laser welder to cut. By guiding you through the process of using the cutting function of a laser welding machine for simple metal cutting, it shows how an integrated laser welder can streamline your workflow and enhance the productivity of any welding and cutting task. The handheld laser welder’s precision, versatility, portability, and efficiency make it an excellent choice for a wide range of metal cutting applications. Whether you’re tackling thin metal sheets or more intricate parts, the integrated system not only ensures fast, clean cuts but also reduces material waste, ultimately improving both the efficiency and quality of your metal project.