Laser marking is the use of a laser beam to engrave permanent markings on the surface of a variety of different substances. There are many types of laser marking machines, the common ones are fiber laser marking machine, UV laser marking machine and CO2 laser marking machine. Each of them has unique features and advantages and is suitable for different application scenarios. Therefore, it is important to understand the difference between them for you to choose the right laser marking machine. Especially the difference between UV laser and fiber laser engraving, the materials they are suitable for vary greatly.

Fiber Vs CO2 Laser Marking

Laser

Fiber laser marking machine using fiber laser

CO2 laser marking machine using CO2 gas laser

Laser Wavelength

Fiber laser marking machine laser wavelength is 1064nm

CO2 laser marking machine laser wavelength of 10.64μm

Material Applications

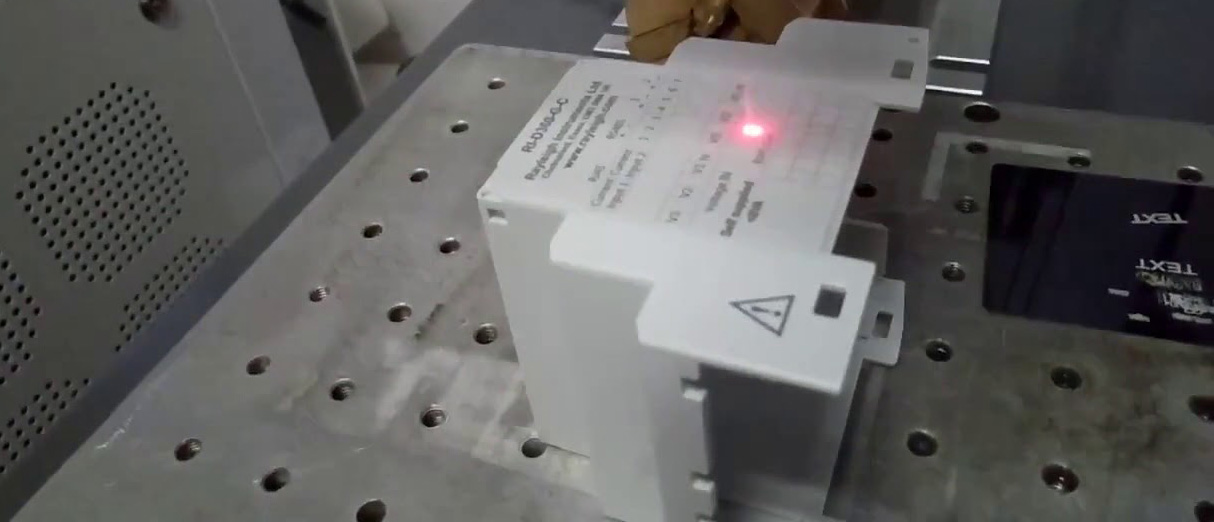

There are significant differences in applicable materials between fiber laser marking machines and CO2 laser marking machines. Fiber laser markers are suitable for marking metals and some specific non-metal materials, but most non-metal materials such as ceramics, wood, leather, and cotton fabrics are not suitable. In contrast, CO2 laser marking machines are suitable for marking most non-metal materials but are not suitable for metal materials.

CO2 laser marking machine industry applications and applicable materials: Suitable for paper, leather, fabrics, organic glass, epoxy resin, woolen products, plastics, and ceramics, crystals, jade, and bamboo products. Widely used in various consumer goods, food packaging, beverage packaging, pharmaceutical packaging, architectural ceramics, clothing accessories, leather, textile cutting, crafts, rubber products, shell nameplates, denim, furniture, and other industries.

Advantages of CO2 Laser Engraving

1. Broad Material Compatibility: CO2 lasers effectively mark a wide variety of non-metals due to their highly absorbed 10.6 µm wavelength, while Fiber lasers excel on metals and select non-metals.

2. Minimal Thermal Damage: CO2 lasers minimize heat diffusion in sensitive materials, ensuring cleaner, high-contrast marks without deformation. Fiber lasers may cause more thermal stress on non-metals.

3. Versatile Marking Techniques: CO2 lasers offer a broader range of marking styles on non-metals, from shallow etchings to deep engravings and color changes. Fiber lasers provide fewer options outside metal marking.

4. Cost-effectiveness for Non-Metal Applications: CO2 lasers can be more budget-friendly for businesses focused on non-metals, with lower initial costs and less expensive consumables compared to Fiber lasers.

5. Large Working Areas and Speed: CO2 laser marking systems often feature larger marking fields and can accommodate multiple parts, with high speeds for deep engraving or low-conductivity materials. Fiber lasers may be less advantageous on non-metals.

CO2 laser engraving vs. Fiber laser engraving in compatibility with non-metals, thermal sensitivity handling, marking versatility, cost-efficiency for non-metal applications, workspace versatility, and environmental compatibility. These advantages make CO2 lasers the preferred option for industries needing to mark, engrave, or process diverse non-metallic materials while maintaining quality and efficiency.

Bottles

Chemical bottles

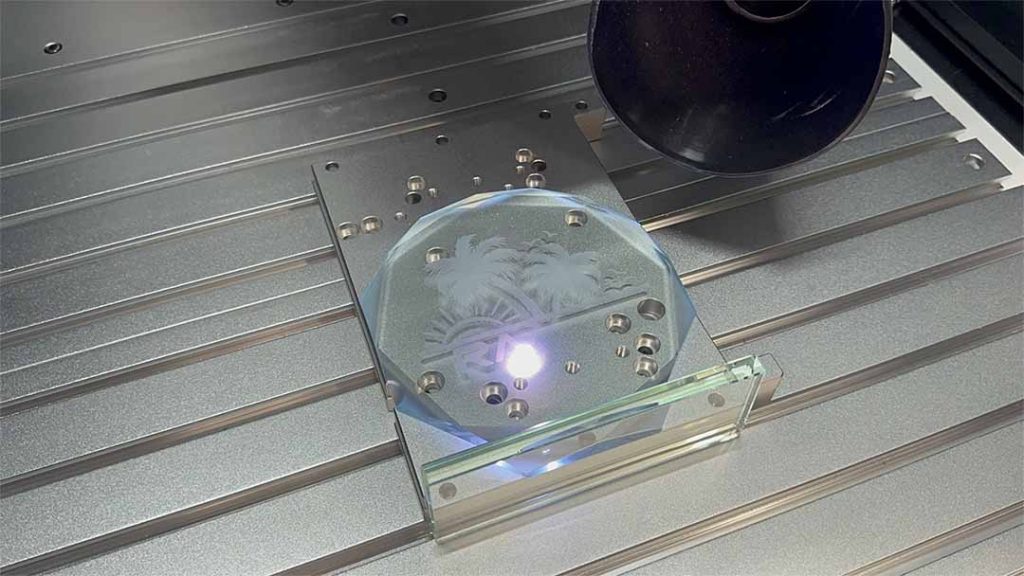

Glass wafers

Electronic PCBs

Earbuds

Wood marking

Difference between UV Laser and Fiber Laser Engraving

Laser Technology

The fiber laser marking machine employs rare-earth-doped glass fiber as the gain medium laser, with a wavelength of 1064nm. The UV laser engraver utilizes a wavelength of 355nm ultraviolet laser. The 355nm UV laser focuses on a very fine spot, achieving marking effects by directly breaking molecular chains of substances with short-wavelength laser, thus significantly reducing mechanical deformation of materials. It is considered “cold light” and is primarily used for ultra-fine marking and engraving.

Processing Methods

The fiber laser marking machine uses laser for physical marking, mainly processing the surfaces of products and materials, constituting a thermal processing process. In contrast, the UV laser marking machine employs a cold processing method, which is a chemical processing approach. Laser chemical processing involves laser penetrating into product materials for processing, offering higher precision and control.

Applications

The fiber laser marking machine is primarily suitable for laser marking on various metal surfaces. It finds extensive applications in graphic marking for integrated circuit chips, computer components, industrial bearings, watches, electronic communication products, aerospace components, various automotive parts, household appliances, hardware tools, molds, wires, and cables in batch production lines.

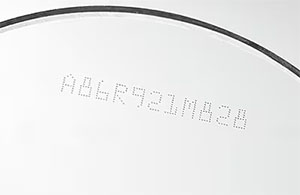

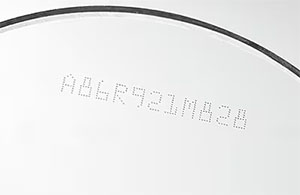

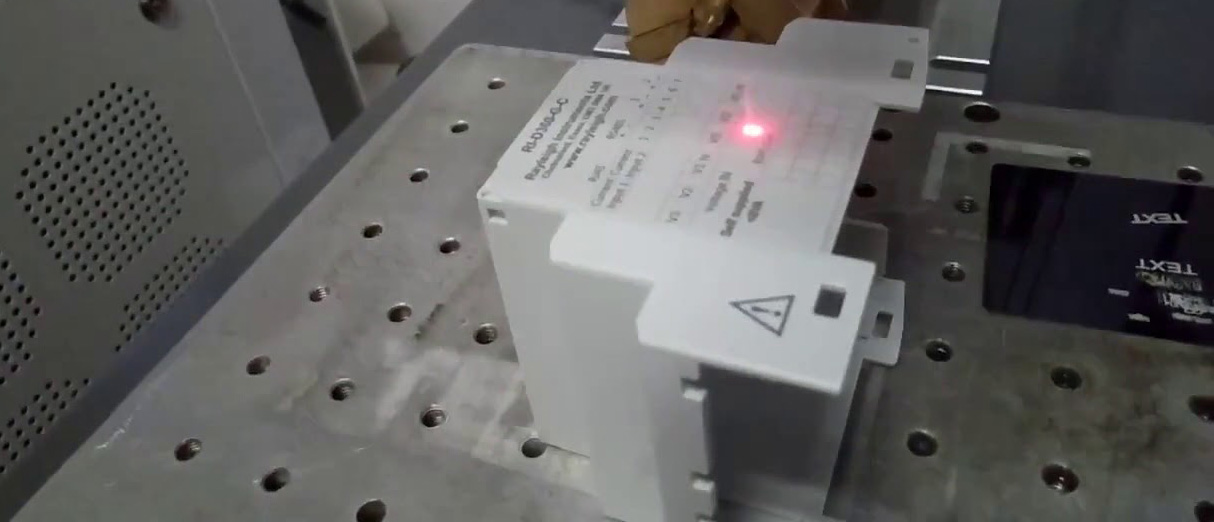

The UV laser marker is particularly suitable for fine processing in the high-end market. It can cleanly and non-contaminating mark on the surfaces of polymer material packaging bottles for cosmetics, pharmaceuticals, and accessories. Additionally, it can be used for marking and scribing flexible PCB boards, processing silicon chip micro holes and blind holes, marking 2D codes on LCD glass, drilling holes on glassware surfaces, coating marking on metal surfaces, plastic keys, electronic components, and complex graphic cutting on silicon wafers and other fields.

UV Laser Marking Plastic: The UV laser marking machine has good adaptability to all kinds of plastic materials, including ABS, PC, PP, PE and so on. Due to the short wavelength of UV laser, it can efficiently make fine markings on the surface of plastic, not only without damaging the surface of the material, but also with clear and visible markings.

UV Laser Marking for Glass: UV laser has better marking effect on glass. It can produce small but clear markings on the surface of glass, which is widely used in the field of glass handicrafts and glassware.

Ceramics: Ceramic materials usually require high energy laser for marking due to their high hardness and good wear resistance.

Rubber: For rubber and rubber products, UV laser marking machine also performs well. It is capable of marking rubber surfaces with high precision and is commonly used in the production and management of rubber products.

Paper and Fiber Materials: UV lasers are also better at marking paper and fiber materials. It can perform high-resolution marking on these materials and is suitable for fields such as the packaging industry and stationery products.

UV laser marking machines utilize high-energy laser beams to mark information such as logos, graphics, trademarks, production dates, and instructions onto workpieces. These markings are persistent, unique, and resistant to counterfeiting. Unlike traditional inkjet printers, UV laser marking machines do not require consumables, resulting in cost savings and environmental benefits. They have overcome issues associated with pollution, consumable usage, faults, and maintenance common in inkjet printing machines. With a wavelength of 355nm, UV lasers create small focal spots with minimal heat effects, resulting in clear and aesthetically pleasing markings. This makes them ideal for marking tiny fonts and intricate patterns, particularly on beverage plastic bottles. UV laser marking machines have become essential tools in the plastics processing industry.

UV Laser Marking Plastic

UV laser marking machines are widely used for plastic packaging. Plastic is light and strong, a good insulator, easy to process, can be produced in large quantities, inexpensive, easy to be molded into different shapes and other advantages, widely used, and has become a commonly used packaging materials.

Why Use UV Laser Cold Marking for Plastic?

Fine Marking Capability: UV lasers with a wavelength of 355nm create small focused spots, ideal for high-precision marking of tiny text, graphics, QR codes, and barcodes on plastic surfaces. Achieving this level of precision is difficult with traditional methods or longer-wavelength lasers.

Low-Temperature Processing: UV lasers operate “cold,” minimizing heat impact on materials by primarily targeting their surface layer. This is crucial for thermo sensitive plastics, preventing deformation or discoloration caused by heat, preserving product appearance and functionality after marking.

Excellent Contrast: UV lasers induce chemical reactions in plastics, resulting in clear and high-contrast marks, even on transparent or light-colored surfaces. This reaction alters colors or textures subtly, enhancing mark visibility and durability.

Non-Destructive Marking: UV lasers ensure minimal mechanical damage to plastic substrates due to their non-contact processing and precise energy control. This preserves the original surface quality and mechanical properties, essential for applications requiring smoothness or integrity.

Wide Material Adaptability: UV laser marking machines handle various plastics, including special materials like PC, PVC, PA, and POM. This versatility suits environments with diverse material requirements and small-batch production.

5w UV laser marking machine is particularly suitable for plastic bottles. With a UV laser coder, key information such as production dates, batch numbers, and anti-counterfeiting labels can be accurately marked on plastic bottles, enabling traceability and anti-counterfeiting measures. When UV laser marking PET bottles, the effect is fine, with clear and durable marks. Due to its excellent beam quality and small focused spot, there is minimal heat impact on the processing area, avoiding issues such as material burning. When using a 355nm UV laser coder for laser marking on plastic packaging (especially PET bottles), it interacts uniquely with the plastic surface, creating a frosted effect on the bottle or container, resulting in visible and durable codes. Through laser coding, key information such as production dates, batch numbers, and anti-counterfeiting labels can be accurately marked on plastic bottles, facilitating traceability and anti-counterfeiting measures.

UV laser marking is preferred for its precision, low-temperature operation, high contrast, non-destructiveness, material adaptability, and cost-effectiveness. It finds extensive use in industries such as food, pharmaceuticals, electronics, automotive parts, and packaging, meeting modern manufacturing standards for quality, traceability, aesthetics, and sustainability.

Fiber, green, UV, and CO2 laser marking machines can all be used for marking on plastics.

- Fiber: Suitable for marking on plastics with higher melting points (e.g., PC, ABS).

- Green: Suitable for almost all types of plastic materials.

- CO2: Mainly suitable for acrylic and rubber.

- UV: Suitable for all types of plastic materials, primarily used in the high-end market for ultra-fine processing. The UV laser has a minimum line width of 0.01mm, compared to 0.02mm for green lasers, resulting in better marking precision.

The adaptability of different lasers affects marking quality and speed, so when choosing a laser marking machine, product and processing requirements should be considered to determine the most suitable type.

How to Choose Fiber CO2 UV Laser Marker?

Laser Source Selection

For materials such as metal, plastic, label paper, etc., it is suitable to use fiber laser marking machine with longer wavelength.

For materials such as bamboo, wood, fabric, ceramics, acrylic, etc., it is suitable to use CO2 laser marking machine with shorter wavelength.

For heat-sensitive materials such as film, fruit, eggs, cartons, reinforced glass, etc., suitable for the use of UV laser marking machine with moderate wavelength.

Laser Power & Product

Laser power is critical in determining processing speed and results.

UV lasers are generally low power (1.2W) for engraving paper, film, plastics, etc., but higher power (3W or 5W) is needed for glass.

Fiber lasers are suitable for marking hardware, generally 20W is sufficient, but for high efficiency and speed, 30W or higher power is required.

Hardware Configuration

Laser equipment in the use of precision, engraving effect, speed and with automation, customized auxiliary tools and other requirements, in the sample and out of the program process to confirm in detail. Next need to consider the life of the marking machine, stability, portability, after-sales service.

Precision and Speed

In terms of precision, UV lasers have the advantage of shorter wavelengths, which can achieve extremely fine feature size and high resolution marking. Fiber lasers offer superior accuracy for metal cutting and welding applications. CO2 lasers provide a balance between precision and speed, making them suitable for applications that require both.

Costs

CO2 vs. fiber vs. UV lasers, CO2 laser engraving machines are generally more cost effective, especially for low power applications. Fiber lasers, while initially more expensive, offer higher efficiencies and longer lifetimes, thus reducing operating costs over time. UV lasers tend to be more specialized and costly.

They can be categorized by style as handheld laser marking, assembly online flying laser marking, split laser marking, desktop laser marking, and non-standard customized models, etc. Choose the right type and accessories for your processing and production line needs. Our strong technical team enables us to provide professional custom marking solutions tailored to your production needs. Just let us know your requirements.

Dapeng Laser insists on strict product quality standards and excellent after-sales service. Our fiber CO2 UV laser marking machines are manufactured with top quality materials and advanced technology to meet high international standards. Each machine undergoes rigorous quality inspection and performance testing before leaving the factory. We are committed to providing a full range of timely response technical support, including installation and commissioning, operation training, maintenance, software upgrades and other services, and are dedicated to solving all problems in the process of customer use. We aim to provide customers with high-quality equipment and worry-free after-sales protection, and jointly promote business development and success.