Laser tube cutting machine is a key technology in the modern metal processing field, highly favored for its efficiency, precision, and versatility. In this article, we will delve into metal tube laser cutting machine working principles, components, and key considerations for configuration and selection of laser tube cutting machines to help you better understand this important metal cutting tool.

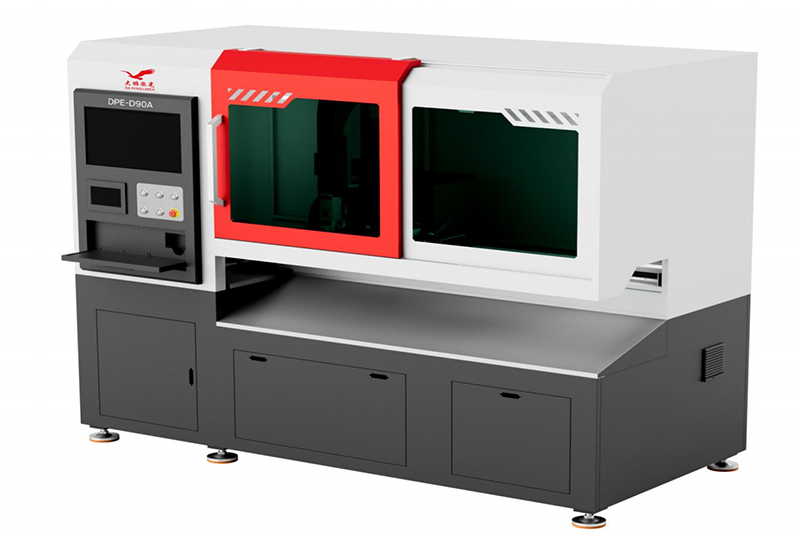

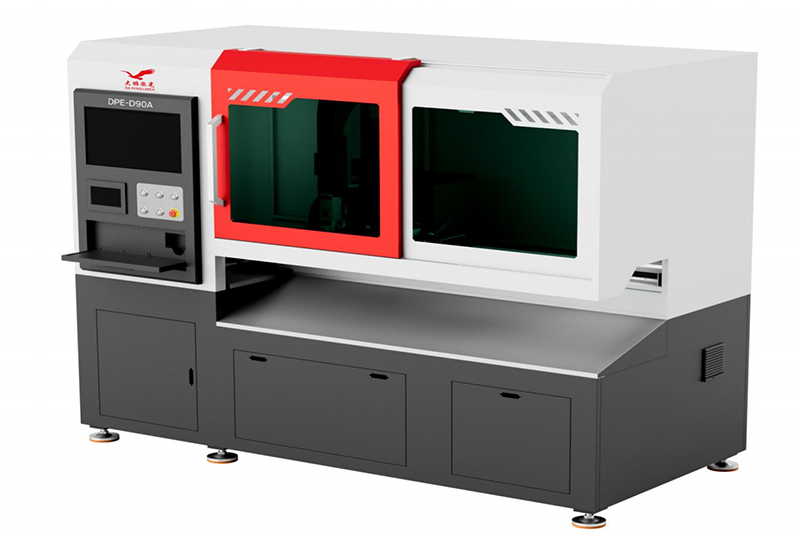

The Components of Fiber Laser Tube Cutting Machine

Laser cutting machine is a precision mechanical device known for its high accuracy and fast speed. With the development of industry and advancements in technology, the demand for machining machinery has been steadily increasing. CNC tube cutting machines use laser beam cutting, drilling and etching of tubes which allows for a wide range of shapes and angles to be cut as required.

Laser pipe cutting machine typically consist of components such as the laser source, cutting head, control system, machine bed (including pneumatic four-jaw chuck, rack and pinion, guide rails, servo motors and drivers, reducers, etc.), cooling system, and loading system.

Laser Source: The laser source is the core of the entire system, generating a high-energy density laser beam used for cutting metal tubes. Common types of laser sources include CO2 lasers and fiber lasers.

Cutting Head: The cutting head is the part where the laser beam contacts the tube material and typically includes a focus adjustment device and a nozzle. The focus adjustment device is used to adjust the laser beam’s focal point, while the nozzle is used to spray auxiliary gas to clear molten metal and debris from the cutting area, simultaneously protecting the lens from contamination.

Control System: The control system serves as the brain of the laser tube cutting machine, responsible for controlling the operation of the laser source, motion system, and other critical components. It typically includes a computer, software, and sensors for monitoring the cutting process and ensuring precise cutting.

Machine Bed (including chuck, rack, guide rails, servo motors and drivers, reducer, etc.): The machine bed is a critical component used for securing and moving metal tubes. The pneumatic chuck is employed for clamping the tube material, while the rack and guide rails provide precise positioning and movement of the tube. Servo motors and drivers are responsible for accurately controlling the tube’s motion, and the reducer reduces the motor’s speed to enhance cutting precision and stability.

Cooling System: Laser cutting generates a substantial amount of heat, and the cooling system is used to cool the laser source and other critical components to prevent overheating. This helps extend the equipment’s lifespan and maintain cutting quality.

Loading System: The loading system is employed to feed metal tubes into the laser cutting area for processing. It can include various devices such as conveyors, automatic loading robotic arms, etc., to enhance production efficiency and automation levels. It is suitable for round tubes, square tubes, rectangular tubes, and channel tubes, providing fully automatic loading. Simply hang the raw material in batches on the material rack to achieve the entire process: automatic loading → automatic feeding → automatic arrangement → automatic cutting → automatic unloading.

These components work together to enable the tube laser cutting machine to efficiently and accurately cut metal tubes, widely used in metal processing processes in industries such as manufacturing and construction, among others.

2 Axis 3 Axis Tube Cutting Machine

2-Axis Laser Cutting Machine for Tube:

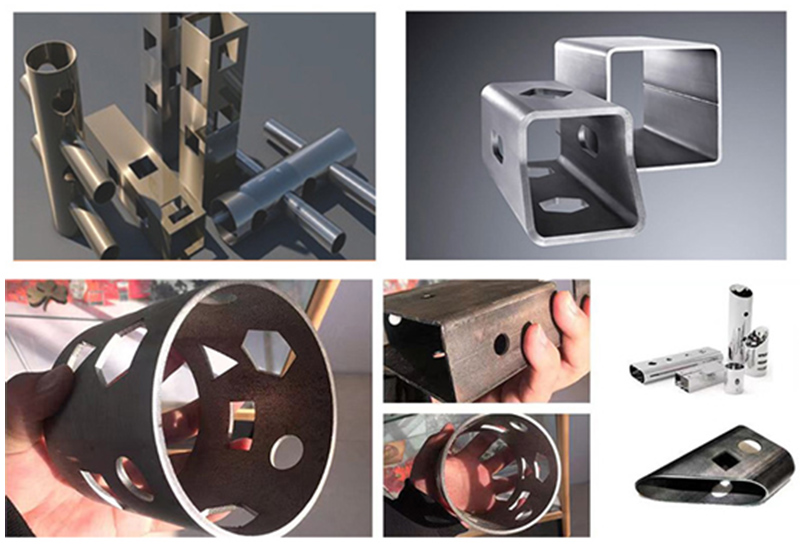

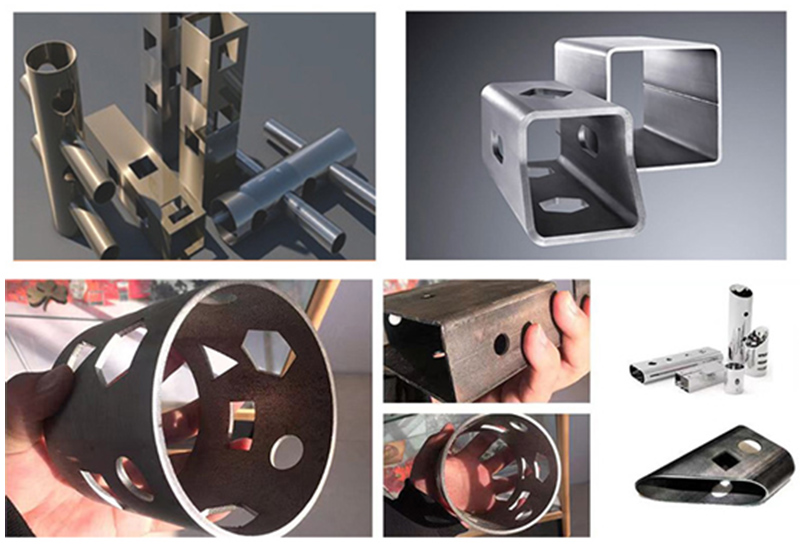

2-axis metal tube laser cutting machine typically features two motion axes, typically the X-axis and Y-axis. This type of machine is suitable for cutting tube materials with simple curved shapes. Common applications include cutting circular, square, rectangular, or other basic shapes of tubes, such as pipes, metal frames, display racks, and more.

3-Axis Tube Laser Cutting Machine:

A 3-axis tube laser cutting system comprises three motion axes, typically the X-axis, Y-axis, and Z-axis. This type of machine can accurately cut tube materials in three-dimensional space, making it better suited for complex cutting tasks, including bevel angles and inclined cuts. They are more flexible and can adapt to a variety of tube shapes and requirements. Common applications include cutting tube materials with intricate curves, angles, or profiles, such as steel components, automotive exhaust pipes, aerospace components, and more.

Additionally, there are more advanced multi-axis laser cutting machines available for highly complex cutting tasks.

How Does a Metal Tube Laser Cutter Work?

1. Loading Rack: Pipe components are hoisted onto the loading rack as whole bundles.

2. Transport Equipment: Pipe material are sequentially transferred to the feeding mechanism, ready to be fed based on demand.

3. Feeding Mechanism: Automatically moves the pipe components to the loading and unloading system according to data signals while ensuring an adequate supply of raw materials for continuous operation.

4. Positioning Calibration System: Corrects the position of pipe components to ensure precise alignment within the feeding mechanism’s range on both sides.

5. Feeding Structure: Automatically delivers pipe components to the raw material position of the CNC lathe based on data signals.

6. Gripping Equipment: Clamps and pushes pipe components to the cutting area for laser cutting based on data signals.

7. Cutting: As the gripping equipment A advances to the middle positioning position of the B rotary support point disc, the C gripping equipment starts automatically to the right end of the B rotary disc, continuously performing laser cutting with utmost precision on the edge and corner waste material, ensuring that all laser cutting of the pipe material results in zero waste.

8. Lifting System: Grabs the product workpiece to prevent it from falling naturally, provided that the pipe component is disconnected.

9. Material Receiving System: Automatically descends to a fixed point to complete the material receiving process.

10. Standby: The feeding mechanism prepares for the processing of the next pipe component to ensure continuous production.

Does Laser Cutting Leave Burrs?

Laser cutting of metal workpieces can sometimes result in defects such as burrs or protrusions, commonly referred to as “burrs.” These defects typically occur when the cutting tool enters or exits the metal sheet.

How to Reduce Burr in Laser Cutting?

1. Check if the copper nozzle is loose and if any iron slag is sticking to it.

2. Recalibrate the height adjuster, ensuring that the material is clamped during calibration.

3. Inspect the protective lens of the laser head for damage or black spots and replace it promptly. Before replacement, use compressed air to clean any dust on the laser head and try to replace the protective lens in a dust-free environment, as well as wipe the lens.

4. It may be due to incorrect vertical positioning of the laser focus on the laser tube cutting machine. Conduct a focus position test and make adjustments based on the focus offset.

5. Inadequate output power of the laser tube cutting machine may be the cause. Check if the laser generator is working properly.

6. The cutting speed of the laser tube cutting machine may be too slow. Increase the cutting speed.

7. The auxiliary gas may contain impurities. Check the quality of the auxiliary gas to ensure that the airflow effectively evacuates the molten material before it forms burrs.

8. Excessive auxiliary gas pressure can create turbulence on the material surface, weakening its ability to remove molten material, resulting in wider kerfs and rough cutting surfaces. Conversely, low gas pressure may lead to incomplete removal of molten material, causing slag to adhere to the lower surface of the material. Therefore, need to adjust the auxiliary gas pressure accordingly.

How Much Does a Tube Laser Cost?

Pipe laser cutting machines can cut various three-dimensional irregular pipes, including hexagon, circular, square, and rectangular shapes, with power ranging from 1000W~6000W or even higher. Their prices typically vary based on performance and configuration, generally ranging from $20,000 to $100,000 USD.

Power Output: The power range of pipe laser cutting machines spans from 1000 watts to 6000 watts, with higher power machines usually capable of handling thicker pipes and achieving faster cutting speeds. Machines with higher power output typically come at a higher cost. Different types of metal materials also require different cutting power levels.

Pipe Size and Shape: These machines can cut circular, square, and rectangular pipes, with different machines having varying maximum pipe diameter and length processing capacities. Larger processing capabilities usually translate to higher costs.

Automation and Configuration: Different models of pipe laser cutting machines may have varying configuration dimensions, including worktable size, feeding systems, clamping devices, and more. These configurations affect the size and efficiency of material processing. Depending on the application, pipe laser cutting machines can perform not only simple vertical cutting but also angled cutting, slotting, engraving, and other special requirements, often requiring dedicated accessories.

Component Brands: Different manufacturers may use components from various brand manufacturers. Each brand has different quality standards and brand reputations, which can also impact costs.

DP Laser fiber tube laser cutter manufacturer. This is the ideal place for you to purchase the best tube & pipe laser cutting machines. All machines leaving the factory undergo rigorous quality inspections, ensuring you receive reliable, durable, and high-performance cutting machines. They are primarily used for cutting metal tubes such as 304# stainless steel tubes, 201# stainless steel tubes, galvanized tubes, brass tubes, aluminum tubes, and more. These machines offer fast cutting speeds, high efficiency, and produce clean-cut, burr-free edges.

Three-Chuck Heavy Tube Laser Cutting Machine

The laser pipe cutting machine with a three-chuck design utilizes a single drive gear and triple pneumatic chucks. It is an advanced and efficient equipment designed specifically for professional pipe cutting applications. The machine is available in various power options ranging from 2000W to 6000W, offering comprehensive cutting capabilities. Additionally, optional loading and unloading devices can be incorporated into the machine setup. The cutting performance of this machine stands out with its superior quality, stability, fine cutting, smooth edges, and minimal deformation. It caters to the diverse cutting requirements of different users.

Equipped with this laser pipe cutting machine, users can achieve high-speed cutting of rectangular, square, elliptical, round, and various shaped pipes, as well as angle and channel profiles. The machine ensures exceptional precision, maintaining high accuracy throughout the cutting process. Moreover, it offers excellent cost-performance ratio, making it a highly valuable investment.

5 Axis 3D Laser Tube Cutting Machine

The Industrial 3D CNC laser cutting machine is a cutting-edge tool utilized for precisely cutting three-dimensional metal tubes. It integrates the functionalities of a laser cutting machine with the capacity to cut tubes along multiple axes, allowing for intricate and complex cuts on tubes with various curves, bends, or angles. This equipment finds extensive applications in manufacturing, metal fabrication, and other industries. It facilitates efficient, precise, and automated cutting processes, enhancing production efficiency and reducing labor requirements. Equipped with advanced control systems and software, these machines are capable of performing intricate cutting tasks based on design specifications and models.

The selection of fiber laser tube cutter machine depends on specific application requirements, including the shape of the tube, its thickness, and production volume. Different power levels and cost ranges are available to meet the needs of various industries and projects, so it’s important to choose the appropriate model based on your specific needs. If you would like to know about laser tube cutting and get a free tube laser cutting machine price, please leave a message to contact us and provide information about your samples or details regarding the material, shape, size, and processing requirements of your samples.