Aluminum alloys are widely used in industrial production and daily life due to their corrosion resistance, high strength-to-weight ratio, and aesthetic appeal. They can be processed in various ways, such as in thin aluminum sheet products for frames, cabinets, kitchenware, metal enclosures, window and door manufacturing, and signage. Laser cutting allows for precise cutting of complex shapes and handling materials of different thicknesses, making it a key process in modern manufacturing. This article will explore the advantages of laser cutting aluminum, the challenges that may arise, and how to choose the best laser cutter for aluminum for your needs.

Can Laser Cut Aluminum?

Yes, high-speed laser beams can cut various alloys of aluminum. However, compared to cutting other metals like carbon steel, this process presents some challenges. Aluminum has a higher reflectivity and thermal conductivity, which can affect the laser beam’s power density and focus, potentially impacting the cutting quality.

What is Laser Cutting Aluminum?

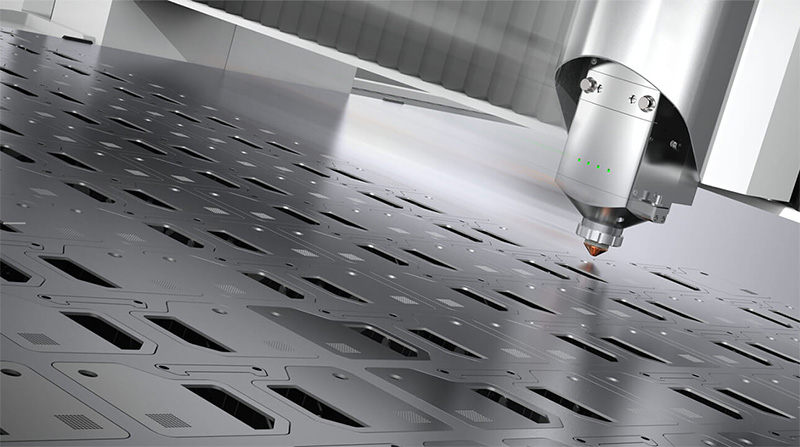

Laser cutting aluminum is a process that uses a high-powered laser to precisely cut and shape aluminum sheets or plates. The laser beam melts or vaporizes the material along a specific path, allowing for intricate designs and clean edges.

Laser cutting is known for its high cutting quality, fast speed, precision, and smooth edges, making it particularly suitable for cutting and engraving aluminum. This method is commonly used in manufacturing for its accuracy and efficiency.

The Benefits of Laser Cutting Aluminum

High Precision:

Laser cutting can precisely follow design drawings with tight tolerances, typically within 0.01-0.05mm.

Non-Contact Processing:

Laser cutting does not require physical contact with the material, so there is no tool wear or deformation.

Smooth Cutting Surface:

The cut surface of laser-cut aluminum sheets is smooth, free of burrs or slag, requiring little to no post-processing.

Minimal Thermal Deformation:

Laser cutting produces a fine cut with concentrated energy and fast speed, resulting in minimal heat transfer to the material and very little deformation.

Material Savings:

Laser processing uses computer programming, allowing the laser to nest different aluminum parts efficiently, improving material utilization and saving material costs.

Fast Processing:

Laser cutting is fast and suitable for mass production.

Flexibility:

Cutting patterns can be quickly changed to meet different design requirements, and various aluminum thicknesses can be handled, making it ideal for cutting complex shapes and small holes.

Material Compatibility:

Laser cutting is suitable for various materials, including aluminum, stainless steel, carbon steel, and more.

Automation & Repeatability:

The process can be fully automated and integrated into CNC operations, ensuring high repeatability and accuracy.

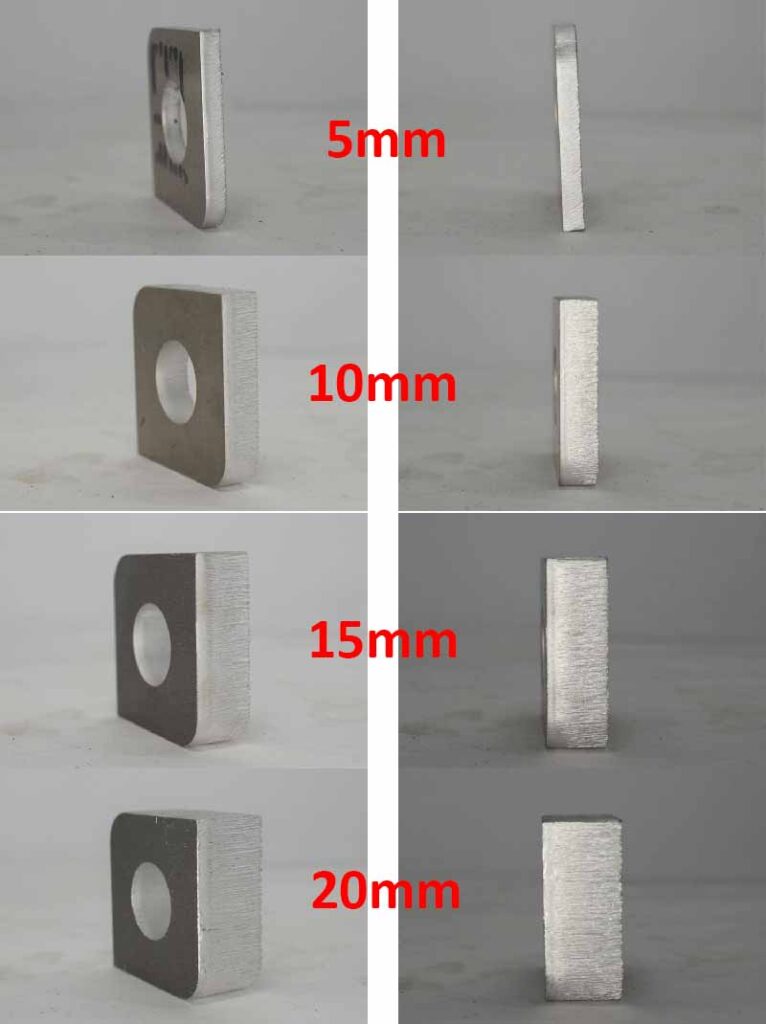

How Thick Can You Laser Cut Aluminum?

Aluminum laser cutting machine is mainly used to process thin aluminum sheet, usually thickness below 5mm. Properly selected high-power laser cutting machines can also cut aluminum with a thickness of 12~16 mm. Fiber laser cutting machines are fast and capable of cutting complex contours, making them an excellent choice for 1mm~20mm aluminum cutting.

| Power | 1000W | 1500W | 2000W | 3000W | 4000W | 6000W | |

| Material | Thickness(mm) | Speed(m/min) | Speed(m/min) | Speed(m/min) | Speed(m/min) | Speed(m/min) | Speed(m/min) |

| Aluminum(N2/Air) | 1 | 8.0-10.0 | 8.0-10.0 | 10.0-15.0 | 28.0-35.0 | 30.0-39.0 | 50.0-60.0 |

| 2 | 3.8-4.5 | 3.8-4.5 | 5.0-6.0 | 12.0-16.0 | 12.0-22.0 | 22.0-35.0 | |

| 3 | 1.4-2.0 | 1.4-2.0 | 2.5-3.5 | 6.5-8.0 | 6.0-13.0 | 12.0-18.0 | |

| 4 | 1.4-2.0 | 3.5-5.0 | 3.8-5.5 | 9.0-12.0 | |||

| 5 | 0.8-1.0 | 2.5-3.5 | 2.8-4.0 | 4.5-8.0 | |||

| 6 | 1.8-3.0 | 2.5-3.5 | 3.8-6.0 | ||||

| 8 | 0.9-1.3 | 0.8-1.6 | 1.8-3.0 | ||||

| 10 | 0.5-1.0 | 1.0-2.1 | |||||

| 12 | 0.8-1.5 |

The Challenges of Laser Cutting Aluminum

When laser cutting aluminum alloys, the high reflectivity of the material can reflect much of the laser beam, leading to insufficient energy and poor cutting performance.

To improve the aluminum cutting effect:

1.Choosing the right laser:

Fiber lasers are widely used for metal cutting, especially for common metal materials such as stainless steel and aluminum. Fiber lasers are favored for their high efficiency, low maintenance and excellent beam quality. When cutting aluminum alloy, choosing the appropriate fiber laser can significantly improve the cutting quality and efficiency.

2. Adjustment of laser parameters:

Laser parameters are critical to cutting results. Compared with cutting carbon steel, cutting aluminum alloy usually requires higher power, and the power, cutting head height, pulse frequency and other parameters need to be adjusted according to the nature of aluminum alloy. The focus position and cutting speed also need to be adjusted according to the material thickness.

As an expert in laser equipment, we have experienced engineers who can help you debug the machine and make samples to find the best cutting parameters.

3. Selection of Nitrogen (N₂) as auxiliary gas:

Auxiliary gases help to increase cutting speed, reduce oxidation and heat-affected areas, and remove molten material. When laser cutting aluminum, the use of Nitrogen (N₂) can effectively prevent oxidation of the cutting surface, keep the cutting edge clean and smooth, and also improve the cutting quality and cutting speed.

4. Surface treatment:

Coating the surface of aluminum alloys with specific coatings or laminates reduces the reflectivity of the material, which in turn improves the efficiency and quality of laser cutting.

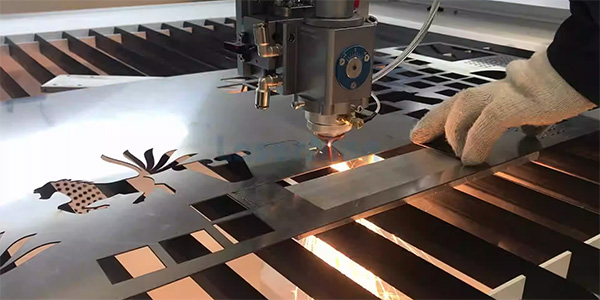

How to Cut Aluminum with Laser?

- Design and Programming: Design the cutting pattern according to the product requirements and write or import the control program of the laser cutting machine.

- Material preparation: Place the aluminum material on the cutting platform and make sure it is fixed and stable.

- Laser Setting: Set the laser power, speed, focal length and other parameters according to the thickness and characteristics of the aluminum material.

- Auxiliary gas: Enable the nitrogen supply to help the cutting process.

- Start cutting: Start the laser cutting machine and cut according to the program.

- Monitoring and Adjustment: Monitor the cutting quality during the cutting process and adjust the parameters as needed.

- Post-processing: After cutting is complete, check the cut quality and remove any residual slag or burrs.

How to Choose the Best Laser Cutter for Aluminum

When choosing the best laser cutter for aluminum, it’s important to consider several factors to ensure the selected equipment meets your production needs and offers a good return on investment.

Power Requirements:

- High-power lasers (6000W~10000W) are ideal for cutting thicker aluminum, providing faster cutting speeds and higher production efficiency.

- Lower-power lasers (1500W~6000W) are better suited for cutting thinner aluminum, typically used for more precise tasks.

Material Compatibility:

Fiber lasers are particularly suitable for cutting aluminum due to their high efficiency and precision. This type of laser can effectively penetrate the reflective layer of aluminum, minimize the heat-affected zone, and provide high-quality cutting edges. If your production involves multiple materials, you should also consider the compatibility of these materials with the laser.

Machine Size and Work Area:

Choose the appropriate table size based on the dimensions of the aluminum materials you need to cut. If you frequently handle large sheets, you should opt for a machine with a larger work area. The size of the work area also affects the overall size of the machine, so factory space availability must be taken into account. Selecting a stable, high-performance cutting machine is crucial because vibrations from the motion system and other mechanical parts can affect cutting quality.

Software and Control System:

User-friendly and powerful software can simplify the operation process and improve work efficiency. The control system should support automated cutting path planning, material identification, and automatic adjustment of laser parameters based on different material thicknesses. Ensure that the control system supports common file formats, such as DXF or DWG, for easy import of design files.

Price and Budget Considerations:

The initial investment includes the machine’s price, as well as potential costs for installation, training, and support services. Operating costs, such as power consumption, consumable replacement (e.g., lenses, gas), and maintenance, should also be factored into the total cost. Given the long-term cost-effectiveness, it’s important to choose a brand that offers good after-sales service and technical support.

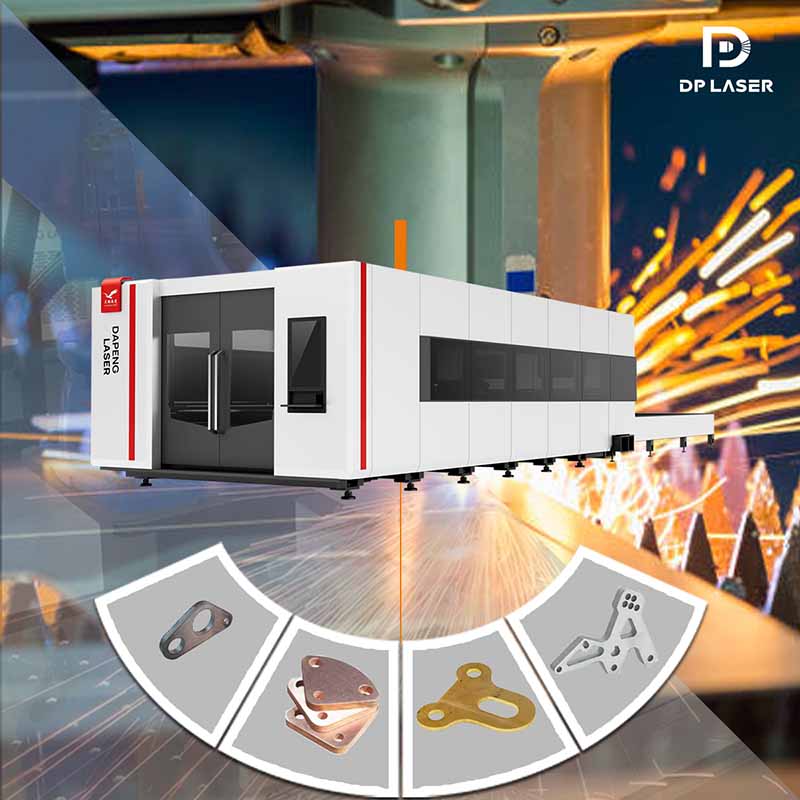

Aluminum Laser Cutting Machine: The Top Brand in China

The DPLASER fiber laser cutting machine is an efficient and precise industrial device designed for fine cutting of various metal materials. It utilizes advanced fiber laser technology, delivering stable beam quality for smooth, burr-free edges. The machine features high-speed operation and low energy consumption, making it ideal for mass production and complex shapes. Additionally, it is equipped with an intelligent control system, ensuring easy operation and low maintenance costs, providing customers with reliable production efficiency and excellent cutting results.

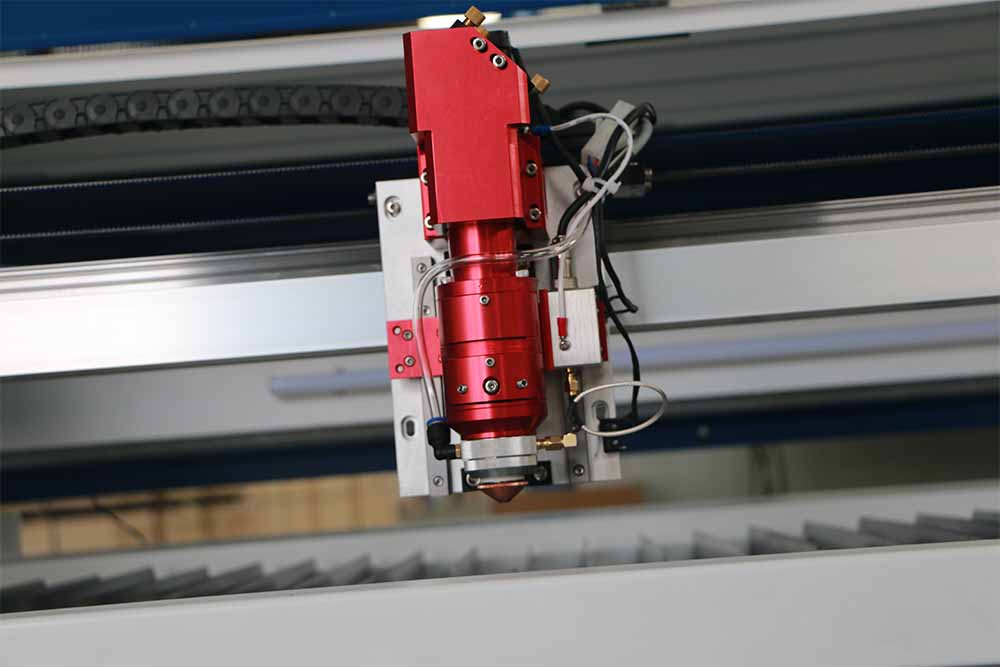

- The F3015 fiber laser cutting machine is equipped with top-brand IPG or Raycus lasers, with power options ranging from 1000W to 12000W, providing broad applicability and flexibility.

- It features a Raytool auto-focusing laser cutting head, making metal cutting more convenient and efficient while ensuring excellent cutting quality.

- The machine uses the Cypcut control system and English interface software, supporting direct import of DXF or AI format files, simplifying the process from design to production and improving work efficiency.

- Equipped with a high-performance Hanli water cooling system, it quickly cools the laser head and source, extending equipment life and maintaining consistent cutting performance.

- The machine utilizes a gear and rack transmission system with Taiwan Hiwin guide rails, allowing for X and Y axis movement speeds of up to 120m/min, ensuring fast and precise cutting actions.

- The application of Japan’s Yaskawa drive motors further enhances cutting speed and precision, ensuring stability and reliability during processing.

- Optional features like an automatic feeding system and rotary attachment enhance the machine’s functionality, offering more possibilities for cutting complex shapes.

- With its high performance, precision, and automation, this fiber laser cutting machine is an ideal choice for sheet metal processing.

Custom Laser Cutting for Metal Aluminum

Don’t hesitate to contact our laser experts to customize your metal laser cutting machine:

1. Free Sample Cutting Experience:

If you’d like to try our free sample cutting or testing service, please send us your CAD files (.plt or .ai formats). We’ll arrange the cutting at our factory, record the entire process on video for your reference, or send the samples directly to you for inspection of the cutting quality.

2. Customized Solution Development:

We offer tailored solutions to meet specific product processing needs, designed to enhance production efficiency and ensure exceptional processing quality.

Final Word:

By gaining an in-depth understanding of the advantages and challenges of laser cutting aluminum for metal, you can better grasp the potential of this process for metal processing. Whether it’s in improving cutting accuracy, handling diverse material thicknesses, or addressing technical challenges in processing, choosing the right laser cutter is key to ensuring success. We hope this article will help you to achieve the best cutting results in practice. If you are considering investing in a laser cutting machine, or looking to enhance your existing processing, start here to explore the best solutions.