In the industrial manufacturing, laser engraving technology has become an important processing method, especially in the processing of stainless steel and other metal materials. Stainless steel laser engraving machine has many advantages such as high precision, high efficiency and non-contact processing, so it is highly favored by the manufacturing industry and art production industry. In this article, we will discuss how to utilize laser engraving technology to process stainless steel, introduce its principles, advantages and applications in industrial fields. You will be able to better understand laser engraved stainless steel and how it can be used in your projects to achieve more detailed and personalized results.

Can You Engrave on Stainless Steel?

Laser engraving is fast becoming one of the most popular methods of engraving metal. When the laser beam reacts with the surface of stainless steel, the temperature of the material rapidly increases and reaches the melting point of the material. Afterwards, you will see the markings on the surface. Laser engraving on stainless steel can be accomplished with certain types of laser machines. For stainless steel engraving, fiber lasers this is not only the fastest and most effective method, but it also ensures that any markings are permanent. The most widely used types of stainless steel are 304 and 316, and laser marking either 304 or 316 stainless steel produces permanent, high-contrast, detailed marks.

Fiber laser engraving machine can meet various engraving needs, providing permanently marking metals:

Laser Etching: A laser beam is utilized to locally ablate the surface of the material to produce a pattern, text or mark. The depth of etching can be precisely controlled to achieve high-contrast black and white markings. Different color markings are often achieved by manipulating laser parameters or surface microstructure.

Laser Engraving: Creates deep, long-lasting markings by vaporizing or stripping the surface of the material. Ideal for scenarios where deeper markings or grooves in the surface are required. Marks are highly abrasion resistant and durable.

Laser Annealing: Commonly used on metallic materials, especially iron-based metals (e.g. steel and stainless steel). The laser slowly heats the surface of the metal, creating an oxidizing reaction underneath and forming a black oxide layer. This marking method retains the surface properties of the material, such as corrosion resistance, and produces a distinctive black mark.

What are the Benefits of Laser Engraving Stainless Steel?

High precision and clarity: Laser marking can achieve high precision and clarity on stainless materials, with fine detail and clear lines.

Fast speed: Laser engraving for stainless steel is fast, greatly improving production efficiency and reducing production costs.

Good durability: Laser marking on stainless materials has good durability, resisting fading or peeling due to environmental factors. This durability ensures the aesthetic appeal of products during long-term use.

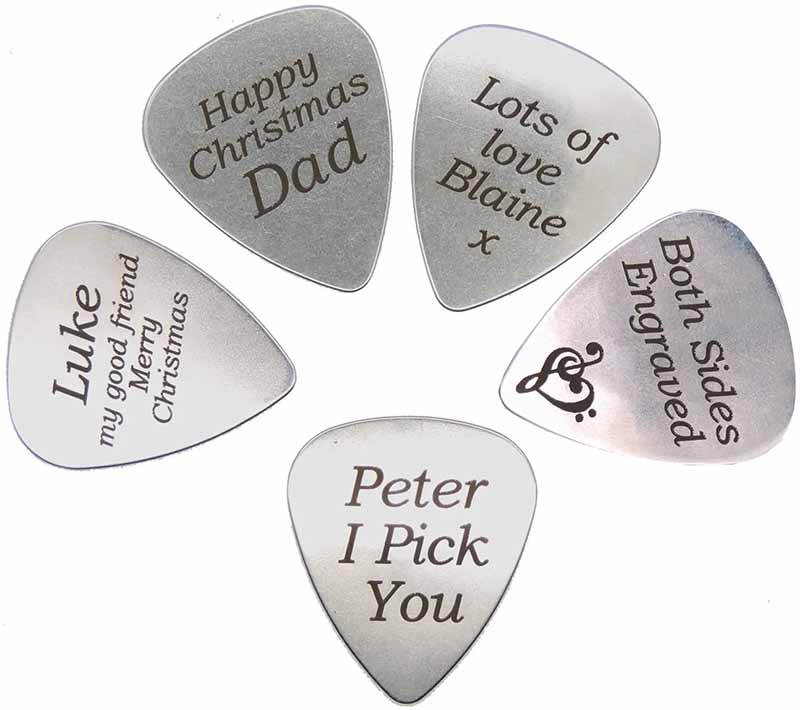

Personalized production: Laser marking can create various marks according to customer needs, including text, patterns, and logos. This customization meets the personalized needs of customers and market changes.

Simple operation: Laser marking is easy to understand and operate, convenient and fast. Just place the stainless material on the worktable of the laser marking machine, adjust the parameters, and start marking.

Wide applicability: Laser marking can be applied to various types of stainless materials, including stainless steel and stainless steel alloys. This wide applicability meets the needs of different customers and market changes.

How to Achieve High Precision Marking on Stainless Steel?

In order to ensure the best results, it is first necessary to proof with excess material. Through several experiments, we can adjust and determine the right marking speed, power, frequency and focal length, among other key parameters. This pre-processing step avoids material waste and reduces the cost of errors, while also helping to optimize the quality and productivity of the final product.

- Cleaning: Prior to engraving, the stainless steel surface needs to be cleaned and pre-treated to ensure smoothness, free from dirt, and oxide, thereby enhancing the adhesion and quality of marking.

- Optimizing Optics and Focus System: If you are using a fiber optic marking machine to engrave stainless steel product, you should adjust the focal length accordingly when marking different objects.

- Adjusting Laser Parameters: Laser power, frequency, pulse width, and other parameters need to be adjusted according to the characteristics of stainless steel and marking requirements. Typically, lower laser power and higher frequency can achieve finer marking effects.

- Accurate Positioning and Calibration: Precise workpiece positioning and machine calibration can avoid errors and deviations, ensuring the accuracy and consistency of marking positions.

- Real-Time Monitoring and Adjustment: Real-time monitoring of marking effects during the process and adjusting as needed are crucial for ensuring high-precision marking. Real-time monitoring of marking quality can be achieved through visual systems or sensors.

- Proper Cooling: Since laser heating of metals can cause temperature rise, timely and appropriate cooling is necessary.

MOPA Laser Color Engraving on Stainless Steel

MOPA laser marking machine is specially designed for stainless steel color marking, through the fine regulation of laser beam energy, can produce rich color effects on the surface of stainless steel. Colorful fonts or patterns directly marked on the surface of stainless steel, marking process is fast, accurate, and will not damage the surface of the stainless steel material, but also other parts of the marking traces. Marking effect is long-lasting and clear without losing color.

MOPA laser engravingis unique in that its laser can independently control the broad and narrow pulses, the use of different pulses on the material processing to achieve multi-color function. It is suitable for stainless steel color marking, aluminum oxide black marking, plastic and metal lettering, paint stripping and other materials processing.

MOPA Laser Marking Machine for Color Marking on Stainless Steel

High-end Consumer Goods: Items like jewelry, watches, and eyeglass frames benefit from exquisite color patterns or text marked on stainless steel components, enhancing product aesthetics and brand value.

Electronic Products: Items such as phone cases, laptop shells, and tablet borders benefit from personalized customization through color laser marking, enhancing visual appeal and market competitiveness.

Tableware and Kitchenware: High-quality stainless steel utensils like knives, forks, spoons, pots, and thermos cups can have trademarks, design patterns, or warning messages added through color marking, combining practicality with aesthetics.

Architectural Decoration Materials: Stainless steel decorative panels, signs, doorplates used indoors or outdoors can achieve diverse decorative effects through color laser marking, enhancing the artistic ambiance of environments.

Automobile Accessories: Interior decorations, key chains, license plate frames, etc., can adopt color marking technology to impart distinctive features and a sense of luxury to the accessories.

Gifts and Souvenirs: Customized gifts, trophies, commemorative plaques, etc., can achieve complex designs and personalized customization through color laser marking, suitable as special occasion souvenirs.

Medical Equipment: Some medical instrument labels require both clarity and durability. MOPA laser marking can achieve color marking while ensuring no contamination, suitable for labeling surgical instruments and medical equipment.

Black Laser Marking on Stainless Steel

Laser black marking is predominantly used to transform the color of metal surfaces, especially aluminum oxide, to achieve a deep or black appearance. This technique involves the application of high-energy laser pulses with a short duration onto the material’s surface, forming an oxide film mere micrometers thick. Post-laser treatment, oxide particles are reduced to the Nano scale. The diminished size of these oxide particles at the Nano-level enhances light absorption and decreases reflection, causing the material’s surface to darken, achieving a black or other dark shade.

Pulse fiber laser markers are capable of creating black or white markings on stainless steel. However, for a broader color palette, MOPA laser marking machines are recommended. Medical device manufacturers often employ ultra short pulse laser black marking for their products.

Laser black marking encompasses both stainless steel blackening and anodized aluminum blackening. The distinction lies in stainless steel blackening directly affecting the steel surface, whereas anodized aluminum blackening targets the oxide film on the aluminum surface. Industrial picosecond lasers, with their narrow pulse widths, high repetition rates, and substantial power, facilitate superior black marking for medical device manufacturers, endowing the marks with properties resistant to corrosion, passivation, and high-pressure steam sterilization.

Picosecond laser marking machine, characterized by ultra-short pulse durations (~10ps), effectively curb thermal diffusion, enabling “cold processing” that minimizes thermal effects on the material surface.

Within an exceedingly brief pulse duration, energy is rapidly injected into a minute interaction zone. The high-density light beam instantaneously alters electron absorption and movement patterns, rendering the laser-treated area anti-reflective and exhibiting a pronounced deep black. This process not only suppresses reflection but also ensures the durability of the markings, which remain corrosion-resistant even after disinfection procedures. Moreover, the non-contact nature of laser marking avoids inducing internal stress, thereby preserving the precision of stainless steel medical devices.

Picosecond lasers find application not only in black marking of stainless steel but are also widely employed in various stages of medical tools manufacturing, encompassing cutting, drilling, and other micro fabrication processes.

What Laser Power do you need to Engrave Stainless Steel?

Stainless steel is harder and more reflective than materials such as wood or plastic, so it requires more power to achieve good engraving results. The amount of power required to laser engrave stainless steel depends on a number of factors, including the depth, speed and accuracy of the engraving. Generally speaking, deeper engraving requires higher power, fast engraving also requires higher power, while higher precision requires lower power, usually between 30W-50W.

The choice of power also needs to be based on the actual engraving requirements, such as material thickness, desired engraving depth, speed requirements, and final accuracy requirements. In addition, the cooling system of the laser engraving machine (e.g. air or water cooled), the type of laser (e.g. CO2 laser), and the laser technical parameters (e.g. light energy, pulse repetition frequency, pulse width) will also have an impact on the engraving results, and therefore these factors need to be taken into account for the specific application, and may need to be tested beforehand in order to determine the most appropriate power setting.

The greatest strengths of laser processing technology lie in its efficiency and precision, which, combined with outstanding flexibility, allow it to be quickly adapted to diverse processing needs and design patterns. This is especially true when dealing with materials such as stainless steel, which can be engraved with clear, primary-colored markings, but can also be fine-tuned with parameters to achieve a deep blackening effect, demonstrating the process’s wide applicability and delicate controllability.

Currently, the fiber laser marking machines for metal with powers mostly above 20W.

1. Power regulation: Increase to more than 15W to ensure sufficient energy input to achieve the blackening effect.

2. Focus positioning: adopt negative defocusing strategy, especially in the blackening operation, the focus needs to be close to the inside of the workpiece, it is recommended to be 1-3mm away from the surface of the material to enhance the absorption effect.

3. Scanning speed: Appropriately reduced to below 100mm/s, to ensure the formation of dark marking at a slow speed.

4. Font and fill optimization: It is recommended to fill the font densely, with a spacing of not more than 0.1mm, and when the font size increases, reduce the filling density accordingly to maintain good marking quality.

5. Frequency setting: maintain the standard or recommended frequency level, without special adjustment.

The above is a stainless steel black marking debugging parameters, the actual application of the specific properties of the material (such as purity) also need to make minor adjustments. Even small changes in parameters may have a significant impact on the final marking effect, therefore, on-site testing and adjustment is indispensable to ensure that the best processing results.

Summary: By understanding the principles and advantages of laser engraving on stainless steel, we can see its enormous potential in manufacturing, art production, personalized customization, and other fields. With continual technological development and innovation, stainless steel laser engraving machine will play an increasingly important role in stainless steel processing, offering more possibilities for product quality and appearance. Contact us now and get cheap laser marker for 304 stainless steel or 316 stainless steel!