There is a question on “Why are laser rust removal so expensive? Why can’t they be a similar price to MIG welders?”

This article will be a series of discussions centered on this question “laser rust removal so expensive”, including the laser rust removal prices, pros and cons of laser descaling machine and how to choose the right laser rust removal equipment for your project.

Laser rust removal machines are typically more expensive than MIG welding machines. Because laser systems require sophisticated optics, high-power lasers and complex control systems to effectively remove surface rust. In addition, research and development costs and relatively limited market demand compared to MIG welders, which use different technology and serve different purposes, contribute to the higher price. MIG welders are typically more widely available and have been on the market longer, leading to more competition and potential for cost reduction. As technology advances and becomes more common, the cost of laser rust removers will decrease over time.

What is Laser Rust Removal & How Laser Rust Removal Works?

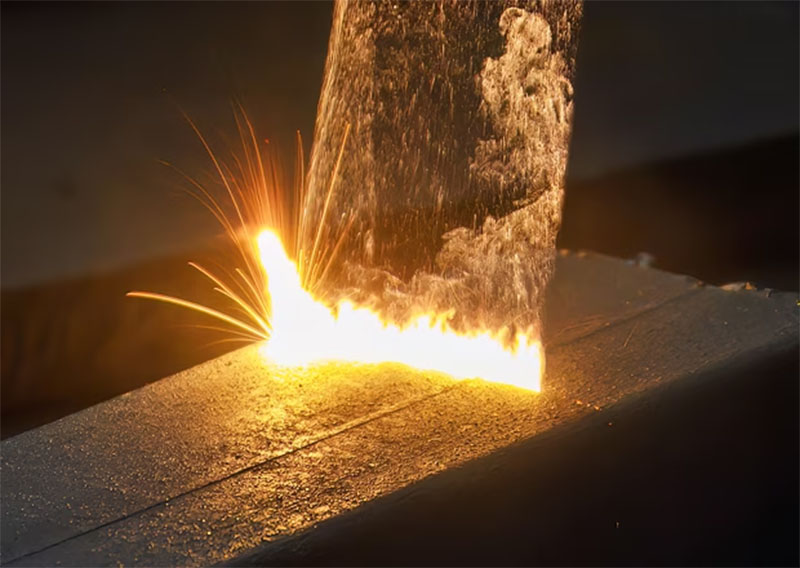

Laser rust removal machines utilize the momentary high-temperature generated by a laser beam to ablate the surface of objects, effectively eliminating surface materials such as rust, coatings, paint, oil stains, oxides, grease, resin, adhesive, dust, stains, residues, and other substances.

Laser rust removal technology boasts a series of advantages. Firstly, it eliminates the need for any chemical agents, conducting cleaning through the “gentle and intangible” nature of light, thereby avoiding mechanical effects and “secondary damage” to the surface of equipment, while ensuring a high level of cleanliness.

Secondly, laser rust cleaning is efficient, fast and cost-effective. Although the purchase of laser cleaning system may require a one-time high upfront investment, but its long-term stable use of low operating costs are relatively low, the hourly operating cost is only about 1 U.S. dollars or so, for the economic viability of the choice.

In addition, laser cleaning systems support convenient automated operation, improving ease of operation.

Is Laser Rust Removal Worth It?

- Laser rust removal technology does not alter the material matrix, but focuses only on removing stains, rust, dust or residue from the surface. The application of this surface cleaning process requires consideration of the material, the thickness of the stains, the laser power and energy level, and other factors. Due to its wide applicability, the application requirements of different materials require adjustments to the parameters of the laser cleaning system to ensure optimal results. This makes laser cleaning a flexible, efficient and advanced technology that is widely applicable to the cleaning needs of all types of materials.

- State-of-the-art technology and equipment usually comes with a high price tag. Laser descaling machines come in a wide range of prices, from a few thousand to tens of thousands of dollars. Typically, the price is closely related to the laser power; the higher the power of the laser, the more expensive it is. However, when buying a fiber laser rust removal machine, you need to choose carefully according to the actual needs, high power is not always the best choice. For example, for simple rust cleaning, low power is sufficient and choosing high power may result in unnecessary damage to the workpiece.

- Laser rust removers are reusable compared to the properties of cleaning agents that are consumable. As a laser device, its price depends mainly on the different configurations. For example, if a more powerful laser generator is used, the price will definitely be higher. Even if the configurations are similar, the cost varies from one manufacturer to another. This is because the cost does not only involve the configuration, but also factors such as shipping, branding, teaching, training, maintenance and after-sales service.

Laser Rust Removal Application

The continuous development of the laser cleaning process has opened up many new opportunities for laser technology in industrial applications, and the application market for this process in microelectronics, machinery manufacturing, construction, automobile manufacturing, medical care, ship cleaning, and cultural relic’s maintenance is extremely broad. Laser rust removal system can not only efficiently clean organic pollutants, but also respond to the cleaning needs of a variety of inorganic substances, especially for metal corrosion, metal particles and dust, etc. has excellent application results.

Mold Cleaning: Laser rust removal can be employed for cleaning various molds, ensuring the cleanliness of mold surfaces, thereby enhancing production efficiency and product quality.

Old Paint Removal from Equipment: In the aviation sector, laser rust removal is widely utilized for removing old paint from equipment surfaces, eliminating rust from hard-to-reach areas such as engine components or landing gear. Laser rust removal can also be applied for surface treatment before painting or coating, which is crucial for maintaining and preserving valuable components.

Exterior Wall Cleaning in Construction: Applied for cleaning the exterior walls of buildings, laser rust removal technology efficiently removes dirt, deposits, and surface rust, rejuvenating the appearance of the building.

Historical Artifact Restoration: Laser rust removal is also employed in restoring antique furniture or metal sculptures and historical artifacts. This technology can remove rust and other surface contaminants without damaging the underlying materials or altering the original appearance of the artifacts.

Electronic Cleaning: In the electronics manufacturing industry, laser rust removal can be used for cleaning circuit boards, connectors, and other precision components, ensuring the reliability and performance of electronic devices.

Precision Machinery Cleaning: For precision mechanical components such as gears and bearings, laser rust removal can precisely eliminate contaminants like esters and oil stains, maintaining the precision and long-term reliability of components.

Nuclear Power Plant Pipe Cleaning: In the nuclear power field, laser rust removal can be applied to clean pipes inside the reactor, ensuring the safety and efficient operation of nuclear facilities.

In summary, laser rust removal technology’s widespread application in various industries provides an efficient and precise solution for cleaning tasks, making it an ideal choice for cleaning processes in many industrial sectors.

Limitations of A Laser Rust Removal Machines

Various Contaminants

When addressing pure iron rust contamination, fiber laser rust removal excels, delivering significant results. However, in the presence of complex mixed contaminants, such as layers of paint and rust combined, laser rust removal machines may exhibit reduced effectiveness. The main challenges include lower processing efficiency and the potential for damaging the underlying metal.

Particularly in scenarios involving mixed paint and rust, the performance of laser rust removal machines noticeably diminishes. This is primarily evident in decreased cleaning efficiency and an elevated risk of causing unnecessary damage to the base metal. Nevertheless, when faced with a singular type of contaminant, laser rust removal machines showcase exceptional performance. Therefore, to achieve a perfect cleaning outcome, a step-by-step approach is needed to remove excess surface materials.

Limited Cleaning Size

While handheld laser rust removal machine have wide-ranging applications and can be used in industries dealing with large parts, their ability to remove rust is limited to specific areas. If it is a large area of stain, it may be very time-consuming and labor-intensive.

How to Choose the Best Laser Rust Removal Machine for Metal?

The operational of laser rust removal involves several key steps.

Firstly, it is necessary to identify the type of contaminants and the characteristics of the substrate material. Based on this information, the appropriate type of laser is selected. Following the principle of optimal selection, ensure that the chosen laser type can remove contaminants without affecting the substrate material. This approach allows for the perfect removal of contaminants while safeguarding the integrity of the substrate.

Taking laser paint removal as an example, the contaminant in this operation is the paint layer, and the substrate material is metal. To clean most effectively, choosing a carbon dioxide laser is most suitable. This is because carbon dioxide lasers have a high absorption rate for paint and a relatively low absorption rate for metal. Consequently, during laser irradiation, it can precisely remove paint while preserving the integrity of the underlying metal.

If you uncertain during the selection laser rust cleaner, feel free to contact us. Our team is committed to supporting you in making informed choices in the field of laser cleaning, providing customized equipment and detailed quotations tailored to your needs. We look forward to delivering high-quality service to ensure the smooth and efficient implementation of the laser cleaning process.

Handheld Laser Rust Remover

Handheld laser rust removal machines are the lightweight, cost-effective choice for small-scale applications. Typically priced in the thousands of dollars, these compact descaling tools provide the ideal solution for on-site cleanup or small-scale descaling projects.

- Portability, these machines are designed to be compact and lightweight, allowing for easy maneuverability and operation in tight spaces or on irregularly shaped surfaces.

- Portable and lightweight, flexible and adjustable parameters, wireless control, etc., which can efficiently remove rust, stains, and oil on the surface of the workpiece.

- Energy Saving and Environmental Friendly. Cost Saving. Wide Material Applicability, Flexible and Efficient Application in Various Industrial Processing Scenarios.

- No Damage to the Base Material. Non-contact Cleaning. No Consumables. No Damage. No Chemical Pollution.

Platform Rust Removal Equipment

Designed specifically for medium-sized descaling projects, they can easily handle a wide range of metal surface challenges. Equipment in this category has a wide price range, from $10,000 to $100,000, depending on equipment parameters and component selection.

Laser Rust Removal Robots

Robotic Laser rust removal systems are the most powerful and widely applied choice. These systems can effortlessly eliminate corrosion from large metal surfaces such as cars, ships or bridges.

Automated Rust Removal: Laser rust removal robots achieve automated rust detection and cleaning. Through laser scanning systems, robots can quickly and accurately identify rusted areas on metal surfaces, then perform targeted rust removal without the need for human intervention. This significantly enhances the efficiency and precision of rust removal operations.

Efficient Operations: Compared to traditional mechanical or chemical methods, laser rust removal boasts higher operational efficiency. Laser energy can be concentrated rapidly, causing rust layers to evaporate or peel off quickly, thereby expediting the rust removal process. The automation of robots further enhances efficiency, as they can work continuously without fatigue or human-related factors.

Precision Rust Removal: Laser technology offers highly precise control over the position and intensity of the laser beam. This allows laser rust removal robots to selectively remove rust from specific areas without damaging the metal surface, preserving the integrity of the treated surface. This is crucial for ensuring the durability and safety of large metal structures.

Data Recording and Analysis: Some laser rust removal robot systems also feature data recording and analysis capabilities. They can monitor parameters such as rust severity and processing time in real-time. This helps formulate more scientifically sound maintenance plans and provides data support for quality control.

How Much Does a Laser Rust Removal Cost

The cost of a laser rust removal machine varies depending on the type of laser and its configuration, ranging from a few thousand to tens of thousands of dollars. For an exact quote, please contact us for a customized pricing plan. We will customize the appropriate laser cleaning system according to your material and cleaning requirements.

Beyond the initial investment, laser rust removal involves ongoing costs, including expenses for the laser source, maintenance and repairs, staff training, and energy consumption. While laser descaling technology tends to be more expensive than traditional methods, its speed and efficiency can result in significant long-term savings.