Infrared Picosecond Laser Marking Machine for Medical

Ultrafast lasers, such as femtosecond or picosecond lasers, are highly effective in marking, drilling, cutting and engraving due to their exceptional precision and minimal thermal impact. Compared to conventional lasers, they produce cleaner edges, finer details, and negligible heat-affected zones, making them suitable for delicate or high-value materials. They also allow for the processing of a broader range of materials, including brittle and transparent ones, with highest accuracy.

Infrared picosecond laser marking and engraving machines use laser beams to permanently mark or engrave various types of materials on their surfaces with superior precision and detail.

Pico-second Laser Marking & Engraving Machine

The pico laser marking machine can create color marking on titanium and black marking on anodized aluminum oxide and stainless steel.

All device identifiers for medical devices, implants, tools, and instruments must be permanently, clearly and accurately marked. This characteristic is important for traceability and transparency of medical products and devices, ensuring that they can be properly tracked and identified throughout their lifecycle. Picosecond laser black marking is widely used in medical implants, surgical instruments and disposable. Therefore, the picosecond laser marking machine is an ideal tool for enhancing quality control, traceability, and safety in the medical industry.

Features

- Superior beam quality (M² < 1.2), supporting PSO, Burst, and FFC modes.

- Compact all-in-one design with high structural stability.

- Long-term operational reliability, suited for 24/7 industrial-grade applications.

- Equipped with GXP 1064 picosecond infrared laser series for enhanced performance.

- Streamlined interface and integrated design for simplicity and reliability.

- Ultrashort pulse width and high peak power, making it ideal for high-precision industrial applications.

|

Laser Source

|

Scanning Mirror

|

|

|

Lens λ=1064nm

|

Control Software

|

|

|

Computer Monitors

|

Laser Chiller

|

|

Advantages of Infrared Picosecond Laser Marking System

The picosecond laser marking machine can replace the nanosecond UV laser marker, CO2 laser marker, fiber laser marker, and MOPA laser marker. The DPLASER picosecond laser marker has some advantages:

Stable Performance

- Homemade seed source (40000hrs lifespan)

- Proven solid-state amplifier technology

- Import of core components

Powerful

- All-in-one machine design

- Burst pulse editing function

- Support PSO function

- Data monitoring and analysis

- Power fast switching function

Low Maintenance Cost

- Modular design, can be maintained separately

- Quick after-sales response, on-site maintenance, low cost

Features:

- Superior beam quality (M2<1.2), support PSO, Burst, FFC mode, integrated design, compact structure, high long-term working stability.

- 24/7 industrial application, GXP 1064 picosecond infrared series laser.

- Integrated design, simple structure, reliable performance.

- Narrow pulse width, high peak power, focus on micro-nano processing field.

- The operation is simple and user-friendly, and the equipment has good stability; the special control software is compatible with Auto CAD, CorelDRAW, Photoshop and other software output.

- Can receive various BMP, JPG, DXF, PLT, AI and other format files.

- Automatically generate various serial numbers, production dates, barcodes, and QR codes.

- Support flying marking and rotating marking.

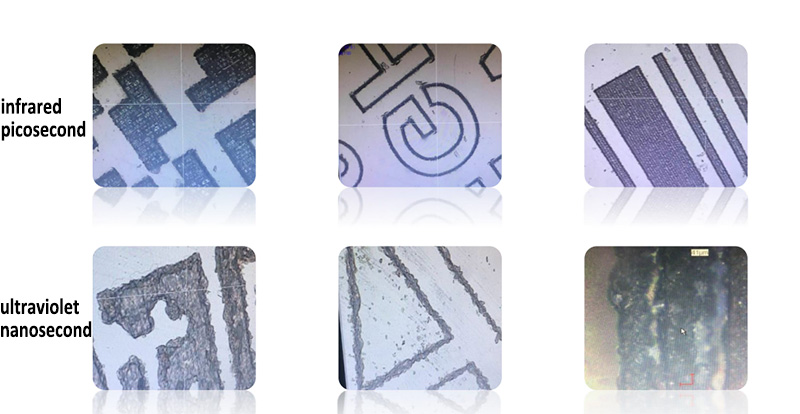

Marking Glass – comparison of infrared picosecond and ultraviolet nanosecond

Ultrafast pulsed lasers, such as femtosecond and picosecond lasers, demonstrate exceptional capabilities in high-precision machining, especially for applications requiring intricate detail processing. By controlling laser parameters, micron-level processing accuracy and the fabrication of complex structures can be achieved. Ultrafast laser technology is widely used in applications such as micron hole drilling, microelectronic component manufacturing, glass cutting and engraving, stainless steel color marking, as well as semiconductor processing, PCB, and FPC fabrication, providing robust support for precision manufacturing.

Picosecond Laser Marking Application:

The picosecond laser can mark a wide range of materials, including metal, plastic, and glass, enabling it to be used for a variety of medical applications.

- Cutting and drilling of brittle materials, frosted glass surface (glass, sapphire and ceramics)

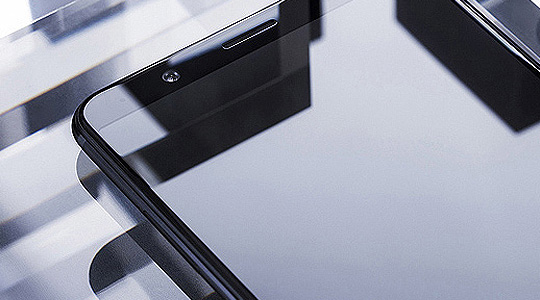

- LCD, OLED screen cutting

- Glassware marked scale – Home Appliance Industry

- Blackening of battery cell, anti-electrolyte corrosion – New Energy Industry

- Laser black marking on medical metal – Medical Equipment

- Acrylic inner carving – Decoration

- Jade deep carving, 3D relief carving – Crafts

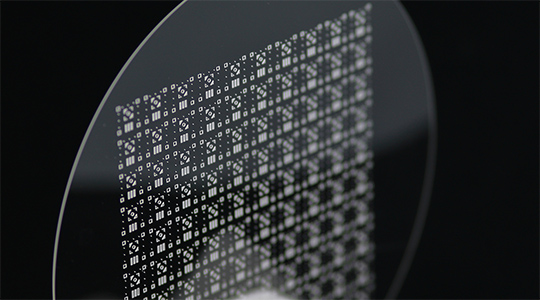

- Marking of wafers – Semiconductor

- Aluminum oxide blackening – Metal Processing

- Ceramic dial scale for smart watch – Smart Wearable

- Infrared picosecond laser marking for black aluminum oxide – Food Packaging

Widely used in integrated circuit chips, moulds, microelectronics, industrial bearings, clocks, aerospace devices, auto parts, wires and cables, medical equipment, and many other fields of graphics and text marking, mass production line operations.

|

|

|

Reviews

There are no reviews yet.