What is a Visual Positioning Laser Marking Machine?

The visual positioning laser marker is a device that combines vision positioning technology with laser marking technology. It utilizes a computer vision system to real-time recognize and locate objects, and then marks and engraves on the object surface using a laser beam. The vision positioning system captures images of the target object, processes them through image processing and algorithms to recognize and locate the object’s position. The control system receives this position information and calculates the motion trajectory of the laser beam, controlling the scanning system to accurately mark and engrave on the object’s surface, ultimately meeting high-precision positioning and marking requirements.

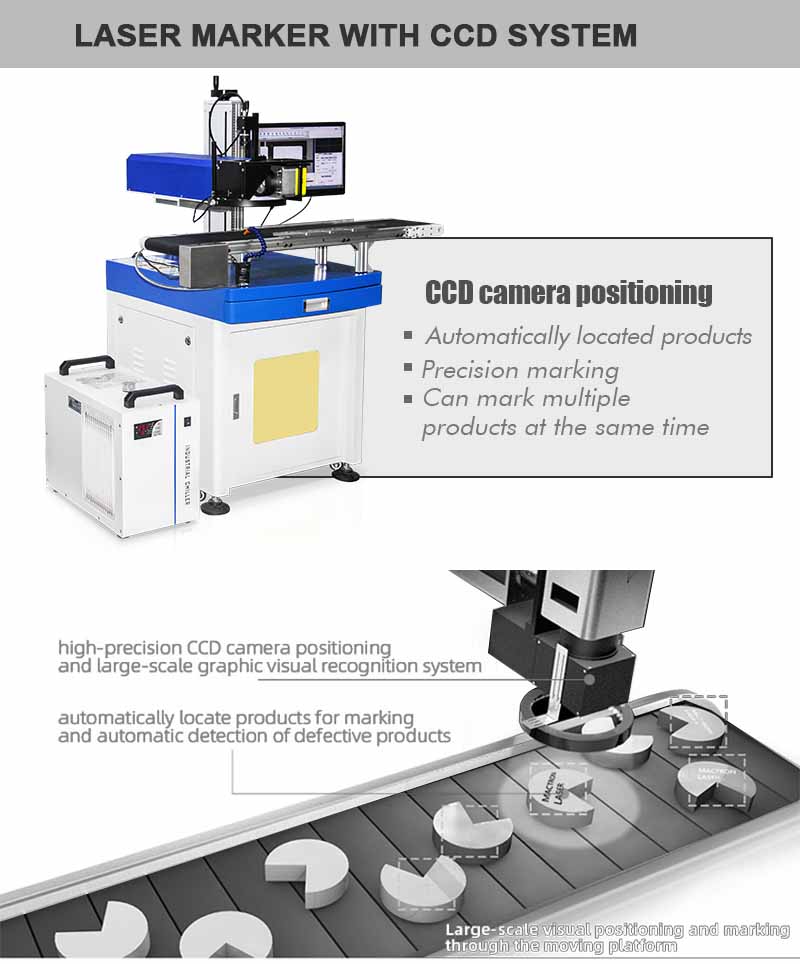

How Does CCD Vision Laser Marking Machine Works?

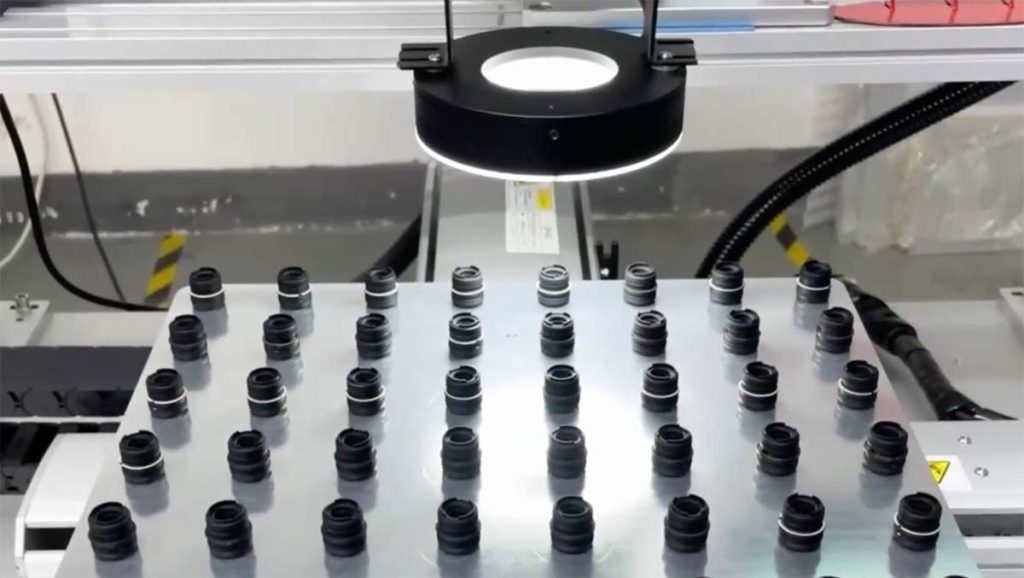

The CCD vision laser marking system realizes efficient and accurate marking of products by integrating vision positioning technology. The core lies in templating and storing the product features as a standard reference. In the actual processing, the CCD camera captures the product image and compares it with the pre-stored template, and the computer quickly completes the position identification and calibration, thus guiding the laser head to carry out accurate marking. This process is not limited by the shape of the product, whether it is round, square or complex irregular shapes can be recognized and processed. Laser marking machine with CCD visual positioning is particularly suitable for small parts, as cumbersome positioning fixtures are no longer required, thus significantly reducing laser marking preparation time and overall processing cycle time.

Flying Online Laser Marking Machine with CCD Visual Automatic Positioning

Visual positioning laser marking machine can often be combined with flying marking equipment to form customized laser marking solutions. These machines integrate a CCD vision system with dynamic on the fly marking technology to automatically recognize the position of the target object and perform accurate laser marking on high-speed conveyor assembly lines.

Vision positioning ensures that the laser can accurately mark in a preset pattern even when there is a slight change in product position, which is particularly useful for high-volume, continuous production lines that require high-precision marking. For example, in industries such as electronic components, food packaging, and automotive parts, fast-moving products need to be marked with high quality and consistency in a short period of time.

Vision positioning systems are widely used in various types of laser marking machines, including fiber laser marking machines, UV laser marking machines and CO2 laser marking machines, which enhance the automation and flexibility of various types of equipment, and combined with the high speed flying fiber laser marking machine, help to achieve a more efficient and accurate modern production line.

What are the Components of Vision Positioning Laser Marking Machine?

1. Laser Source: laser marking machine using a laser as a light source, generating high energy, highly focused laser beam. Common laser sources include fiber lasers, UV lasers, CO2 lasers and so on, according to different marking materials and needs to choose the appropriate laser source.

2. Scanning System: scanning system consists of scanning mirrors and scanning drivers, used to control the laser beam in the two-dimensional plane movement. Scanning system can make the laser beam on the surface of the target object for fast and accurate positioning and movement.

3. Visual positioning system: visual positioning system using a camera or other image acquisition equipment to obtain the image data of the object. Through image processing and computer vision algorithms, it can recognize and locate objects in real time and provide accurate location information.

4. Control System: the control system is the core part of the visual positioning laser marking machine, it receives the position information provided by the visual positioning system, and controls the laser source and scanning system to carry out the corresponding operation. The control system is usually composed of a computer and the corresponding control software, which can be used for parameter setting, marking pattern and marking process control.

What Are the Features of CCD Vision Positioning Laser Marking Machine?

Vision positioning laser marking systems integrate advanced CCD vision systems for

Flexible positioning without the need for fixtures

Abandoning reliance on precise fixtures, this equipment allows workpieces to be smoothly placed in any orientation. Through a high-precision vision system, it rapidly and accurately identifies and locks onto the target position, achieving precise marking.

Rapid switching for high adaptability

New product templates can be imported in just one minute, significantly reducing setup time caused by product changes and ensuring production lines can easily handle diverse marking requirements.

Cost and time reduction

Eliminating the need for dedicated positioning fixtures for each product saves clients from expensive fixture manufacturing costs and reduces time spent on frequent repositioning, thereby improving overall production efficiency.

Intelligent and efficient batch processing

Equipped with intelligent vision positioning systems, the machine can automatically process large batches of products with continuous precision, increasing production capacity by 3 to 10 times and greatly enhancing production rhythm.

Precision algorithm-driven to minimize errors

Advanced visual software algorithms enable the system to independently and rapidly calculate and control each step of operation, eliminating errors introduced by manual operation and ensuring consistent and accurate marking quality.

Single-person, multi-machine operation for improved efficiency

One operator can monitor and control multiple vision positioning laser marking machines simultaneously, significantly increasing the utilization of human resources and reducing labor costs per unit output.

Seamless integration into automated processes

Such laser marking equipment seamlessly integrates with assembly lines, XY-axis moving platforms, and multi-station mechanical equipment, enabling real-time, continuous, and automated laser marking processes, further driving the intelligent upgrade of production lines.

Why Choose a Visual Positioning Laser Marking Machine?

The CCD vision positioning laser marking machine is designed to meet the challenges of marking irregular parts in mass production, realizing real-time accurate part positioning. Traditional marking methods have limitations in feeding, positioning and speed, especially the increased cost and inconvenient operation associated with the high complexity of fixture design and manufacturing.

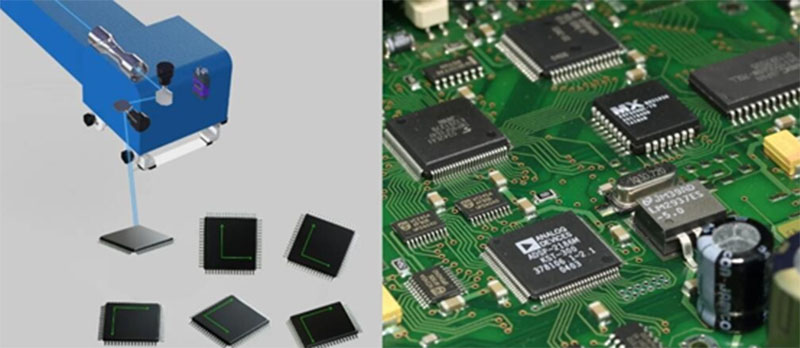

Through the high-precision CCD camera and advanced image processing algorithms, the equipment can flexibly identify and capture the key feature points of the workpiece to be marked, and even if the workpiece position and angle are different, the marking position can be determined and the task can be performed without the need for precision fixtures. It is suitable for those industry application scenarios with large product batches, different product shapes and high positioning difficulty, such as tiny electronic components such as capacitors, integrated circuit (IC) cards, small screws and other precision parts, as well as jewelry and other product series with complex appearance and variable dimensions.

DP LASER can be customized according to customer marking requirements of fiber/UV/CO2 visual positioning laser marking machine for high-speed positioning marking of electronic products production line, electro-acoustic devices, chargers, transformers, relays, connectors, and other electronic parts, automotive parts, medical parts, clothing, hardware small parts, PCB/FPC circuit boards, molds and other high-speed positioning marking.

- Near-zero defect laser marking

- Reduced scrap and errors

- Automatic recognition and positioning of marking positions for ultra-small components, higher throughput and economy, as well as time savings

- Achieve greater accuracy and consistency, high quality laser marking and processing

Laser marking machines integrated with automation technology and CCD vision systems can accurately capture product targets and achieve zero-error positioning, meeting the demand for precise marking. Flexible configuration of laser power and marking parameters according to customer product specifications enhances production efficiency, product quality stability, and cost savings, creating tangible value and benefits for enterprises.

High Resolution

Dapeng Laser’s latest CCD automatic positioning laser marking machine integrates an industry-leading 5-megapixel high-resolution CCD camera, significantly enhancing positioning capabilities in the industrial laser marking. It achieves ultra-fine positioning accuracy at the level of 0.02 millimeters, providing unprecedented marking solutions for precision manufacturing. Regardless of the shape and size of the parts, they can be easily identified and positioned through advanced visual algorithms, achieving precise correspondence between XY axis coordinates and component identification.

CCD Vision Positioning System

Using an innovative CCD visual positioning system, precise positioning and marking can be achieved in all directions, regardless of the angle at which the parts are placed within the laser scanning field of view. This feature not only significantly improves overall production efficiency but also greatly simplifies the manufacturing process for high-precision parts. Generally, the automated laser marking machine with CCD visual positioning is used with assembly line plays a key role in production lines requiring extremely high precision and speed.

Excellent Marking Quality

By choosing different laser sources, optical fiber, co2 UV, etc., it is suitable for different material surfaces. The laser marking machine with visual positioning system can flexibly handle various material surfaces, achieving high-quality marking effects on both smooth and complex textured surfaces.

Conclusion:

As an efficient and precise marking tool for fabrication, the laser marking machine with CCD auto visual position not only enhances production efficiency but also provides a reliable solution for product identification and traceability. We look forward to seeing this technology widely applied in more industries in the future, bringing further innovation and development to manufacturing. If you have any questions or customization needs about laser marking machine with CCD visual positioning, please feel free to contact us anytime. We are committed to serving you wholeheartedly.