What is 4 in 1 laser welding machine? The 4 in 1 handheld laser welding machine consists of a fiber laser generator, handheld laser gun, water cooling system, and a 4-in-1 control system (welding, weld seam cleaning, rust removal, and cutting). Its compact design ensures portability, offering users a flexible and innovative laser solution. The handheld laser welding machine features a lightweight and compact design, making it easy to carry to different job sites or workshops. Compared with traditional welding equipment, it offers simple operation and quick setup, making it highly suitable for beginners. At the same time, with its high welding speed and excellent seam quality, the machine supports various materials and welding modes, making it equally ideal for professional welders.

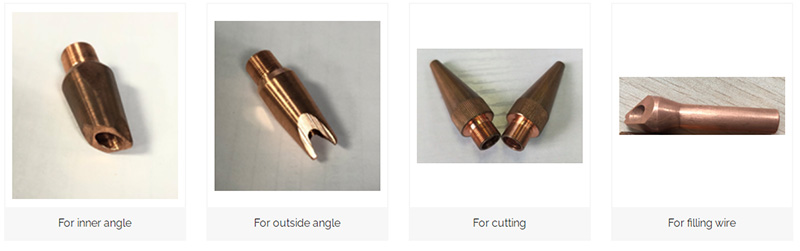

By quickly switching nozzles, focusing lens components, and adjusting system settings, users can easily switch between different modes, simplifying complex tasks and improving efficiency. This versatile machine efficiently handles metal cutting and welding tasks, while also effectively removing rust, paint, resin, coatings, oil stains, and other contaminants from weld seams.

Building upon its 3 in 1 handheld fiber welding machine has been upgraded to a 4 in 1 laser welding machine. It retains the core capabilities of welding, cutting, and rust removal, while adding the new feature of weld seam cleaning. This upgrade allows users to complete all stages of processing—from initial work to final cleaning—on one device, significantly enhancing work efficiency and the utilization of the machine.

4 in 1 Laser Welder Functions

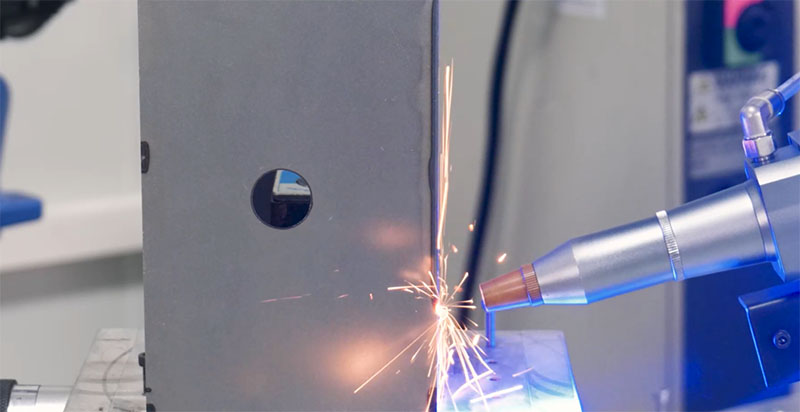

Laser Welding

The 4 in 1 handheld laser welding machine has powerful multi-material welding capabilities, suitable for various metals such as aluminum, copper, and stainless steel. This welding method is fast, with a small heat-affected zone and minimal deformation, making it ideal for precision welding of thin metal sheets. Users can adjust the laser power based on the specific material properties to achieve optimal welding results.

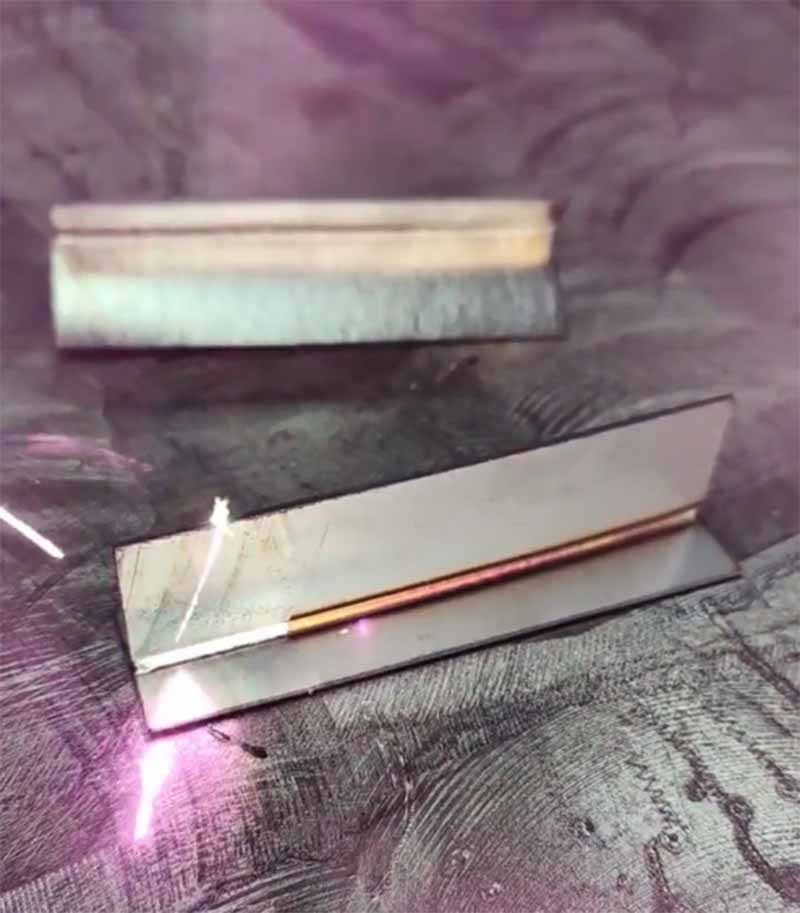

Weld Seam Cleaning

The seam cleaning function of the 4-in-1 laser welding machine uses laser technology to quickly remove oxides and other residues from the weld surface, restoring the original luster and ensuring cleanliness in the welded area. This provides a solid foundation for subsequent processes.

Laser Rust Removal

This 4 in 1 fiber laser welding machine combines laser technology with high-pressure airflow to efficiently remove rust from metal surfaces. This process thoroughly eliminates rust without damaging the workpiece, maintaining its appearance and extending its lifespan. This function is highly valued in industries like ship repair, construction, and equipment maintenance for its efficiency and non-contact nature.

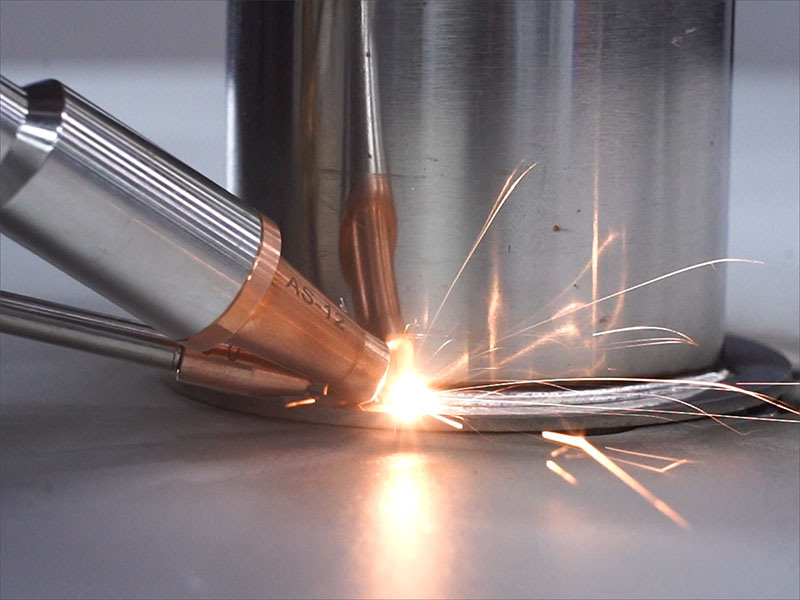

Laser Cutting

With its high-precision laser cutting capabilities, this machine is essential in metal processing and mold manufacturing. Users can flexibly adjust laser power and cutting speed to handle materials of varying thicknesses, meeting diverse production demands with ease.

Advantages of 4 in 1 Laser Welding Machine for Metal

✅ Multi-Functionality

This machine integrates welding, cleaning, cutting, and weld seam cleaning into a single device. This highly integrated design allows it to switch seamlessly between different processing needs, increasing production efficiency, simplifying operations, and reducing the need for multiple specialized machines.

✅ High Welding Quality

The welding process is smooth and produces clean, scar-free surfaces, reducing the need for extensive polishing. With high energy density, laser welding offers superior weld quality, minimal heat-affected zones, reduced deformation and discoloration, deeper weld penetration, and a reliable, fully fused seam.

✅ Efficient Production

The 4 in 1 laser welder employs a non-contact laser beam process, delivering fast processing speeds that significantly enhance productivity.

✅ Ease of Operation

With an intuitive interface, the machine is easy for beginners to learn quickly. Some models also support multilingual interfaces, making them accessible for international users. Additionally, the machine requires minimal maintenance, lowering operating costs. Its compact, multifunctional design is ideal for spaces with limited room.

✅ Versatile Adaptability

Suitable for metals like stainless steel, carbon steel, and aluminum alloys, this machine provides reliable welding solutions for both thin and thick sheets. Its adjustable settings can accommodate various shapes and sizes, meeting the demands of complex structures.

✅ Energy Efficiency and Environmental Friendliness

Compared to traditional welding methods, laser welding generates less heat and smoke, promoting a cleaner work environment and reducing pollution. The process also avoids the need for consumables like welding wires or rods, lowering production costs.

✅ Cost Savings

While the initial investment may be high, long-term savings are significant. The 4 in 1 fiber laser welding machine eliminates the need for multiple devices, enhancing the value of your investment.

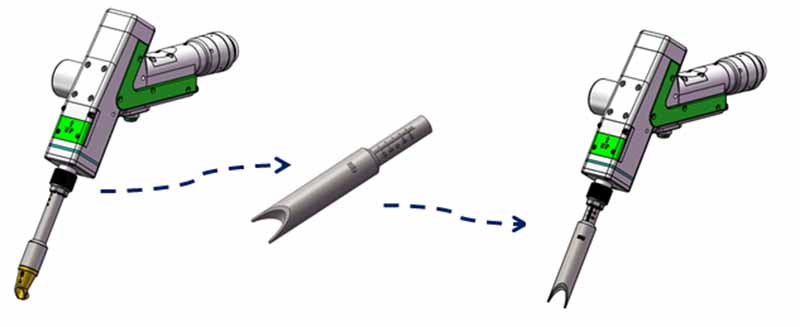

How to Switch the Cleaning & Cutting Modes on a 4-in-1 Laser Welding System

Laser Cutting

Switching between laser welding and laser cutting is straightforward: simply replace the welding nozzle with a cutting nozzle and adjust the control system mode.

Weld Seam Cleaning

To use the weld seam cleaning function: remove the welding nozzle, replace it with the dedicated seam cleaning nozzle, and switch the control system mode.

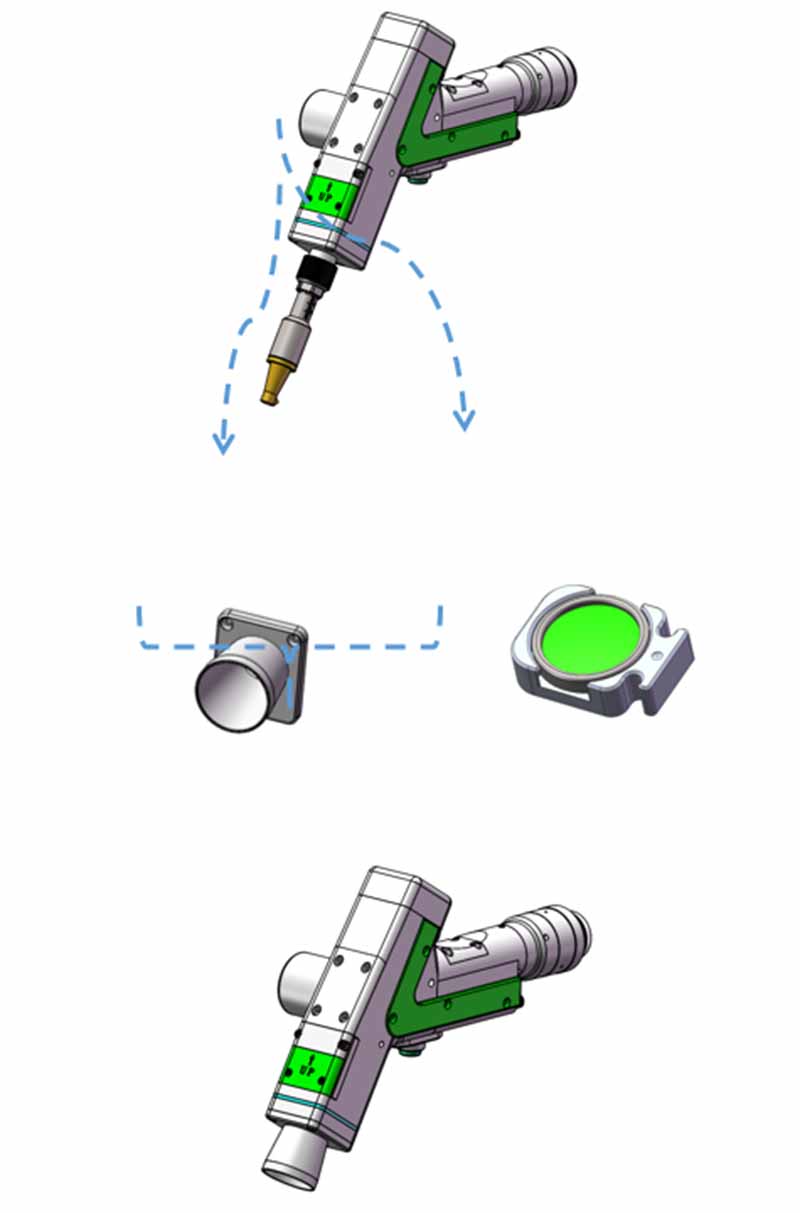

Laser Cleaning Mode

To switch from laser welding or cutting to laser cleaning, just change the focus lens and install the cleaning nozzle. Then, adjust the control system mode, and you’re ready to perform metal rust removal.

The Best 4 in 1 Handheld Laser Welding Machine

The handheld laser welding machine is designed to be lightweight and compact, making it easy to transport between work sites or within workshops. It provides precise control over the welding process, enabling intricate welding on various materials. Equipped with a 4 in 1 laser welding system and laser gun, it offers a power range of 1000W~3000W, suitable for welding materials of different thicknesses. The four-in-one functionality includes welding, cutting, cleaning, and seam cleaning, with quick mode changes achieved by switching nozzles, gun components, and adjusting control settings.

The machine features excellent weld seam cleaning capabilities, with a cleaning width of up to 10mm, ensuring a spotless weld area for high-quality welding. Its powerful rust removal function covers a width of 120mm, making it ideal for large metal surface cleaning, significantly boosting efficiency. Additionally, it performs exceptionally well in cutting metal sheets 1-3mm thick, delivering smooth, efficient cuts along the edges.

✅ How Thick Can a Laser Welder Weld Metal?

Of course, the welding thickness and quality depend not only on the laser power but also on more laser parameters. Please contact us for sample testing to confirm your final requirements. The following table is for reference:

| Laser Power | Stainless Steel | Carbon Steel | Iron | Aluminum | Galvanized Sheet | Brass |

| 1000W | 3mm | 3mm | 3mm | 2mm | 2mm | 1mm |

| 1500W | 4mm | 4mm | 4mm | 3mm | 3mm | 2mm |

| 2000W | 5mm | 5mm | 5mm | 4mm | 4mm | 3mm |

| 3000W | 8mm | 7mm | 7mm | 6mm | 6mm | 4mm |

✅ Design Features

- Lightweight Handheld Laser Head: Weighing just 0.75kg (or under 1kg), this makes it more flexible and convenient to use, offering comfortable handling.

- Red Light Aiming Assistance: Helps improve processing precision by ensuring accurate alignment with the target area.

- Interchangeable Copper Nozzles and Lenses: Allows users to switch between different lens specifications for a variety of applications. The weld seam cleaning width reaches 10mm, with a 120mm rust removal width, and is ideal for cutting sheets 1-3mm thick.

- Automatic Gas Control System: Ensures precise gas flow control during welding to improve weld quality.

- Efficient and Stable Laser Generator: Guarantees stable output power, ensuring consistent welding speed and high-quality results.

- Built-in Water Chiller: Provides efficient cooling, maintaining the machine at optimal working temperatures.

- 10m Flexible Fiber Optic Cable: Overcomes workspace constraints, enabling outdoor and long-distance welding.

- Fully Automatic Wire Feeder: Supports welding wire diameters from 0.8mm to 1.6mm, expanding the material range for welding. Simply switch to the wire-feeding nozzle for wire-fed welding.

✅ Ease of Operation

- Easy to Learn and Operate: The 4-in-1 control system features a simple operation mode, allowing for quick learning and operation. Basic training takes only 30 minutes, which significantly reduces labor costs.

- Preset Process Library: The system includes a library of process parameters for common materials and thicknesses, allowing users to quickly select welding parameters based on material and thickness. Even beginners can achieve high-quality, consistent welds.

✅ Flexibility

Diverse Welding Methods: Capable of welding at any angle, including overlap, butt, vertical, flat angle, inner corner, and outer corner welds. It can weld complex and irregularly shaped large workpieces, providing flexibility for all types of welding jobs. It also supports cutting and easy switching between welding, cutting, and cleaning modes.

Customizable Parameters: Adjustable settings to meet a wide range of processing needs, allowing users to tailor the machine to specific requirements for diverse applications.

✅ Monitoring and Diagnostics

- Real-Time Monitoring: Continuously monitors equipment status to ensure safe and efficient production.

- Automatic Alarm for Abnormalities: Instantly alerts operators when a fault or abnormal condition occurs.

✅ Safety Measures

- Safety Lock Design: Prevents accidental activation, enhancing user safety.

- Professional Master Switch: Allows for quick power shutdown in emergencies to protect operators.

- Automatic Laser Shutoff: Disables the light source when the welding head is lifted, effectively preventing accidental exposure.

✅ Convenience

- Built-In Toolbox: Provides easy storage and access to tools and accessories.

- Versatile Copper Nozzles: Equipped with a variety of nozzle options suitable for diverse tasks.

- Large Universal Wheels: Ensures easy mobility, adapting to different workspace conditions.

✅ Applications

The 4 in 1 handheld laser welding cleaning and cutting machine is suitable for multiple metal processing tasks, including stainless steel, carbon steel, copper, aluminum, and galvanized sheets. Its versatility makes it ideal for various industries such as home appliance manufacturing, cabinetry, staircases, elevators, shelving, ovens, stainless steel doors, window railings, power distribution cabinets, medical devices, communication equipment, battery manufacturing, crafts, and kitchen and bathroom products.

How to choose a 4 in1 Laser Welding Machine?

This newly upgraded handheld laser welding machine features a versatile 4-in-1 multifunctional design, ideal for small to medium-sized production needs. It supports power configurations of 1500W, 2000W, and 3000W, allowing users to select the optimal power level based on specific application requirements to achieve the best welding results across various scenarios. Whether working with thin or thick plates, this machine handles a wide range of materials and thicknesses with ease, greatly expanding its range of applications.

The laser welding machine price is influenced by various factors, including laser power, model type, specifications, and brand. For handheld laser welding machines, the market offers a variety of configurations, accessories, and clamps to meet specific user needs. The 4 in 1 laser welding machine price range from approximately US$2,000~ US $4,000.

It’s important to recognize that the true cost of purchasing a laser welding machine goes beyond the initial price. Additional expenses, such as maintenance, operation, and technical support, must also be factored in. However, from a long-term perspective, investing in a high-quality Dapeng handheld laser welding machine will offer significant returns.

Dapeng laser welding machines are known for their ease of use, quick learning, and exceptionally low failure rates. These features greatly enhance work efficiency, accuracy, and productivity, ultimately delivering substantial economic benefits to businesses. To ensure the best investment, it’s recommended to carefully assess your specific needs and budget when choosing the right model and configuration.

In short, the 4 in 1 laser welding machine for metal brings unmatched versatility and efficiency to a variety of industrial applications. By combining welding, cutting, cleaning and other functions into one machine, it helps streamline operations, reduce costs and increase productivity. Whether you work with metals, plastics or other materials, this all in one laser welder is designed to meet your every need with precision and reliability. Explore our advanced 4 in 1 handheld laser welding system to enhance your manufacturing process. Start getting a quote now!