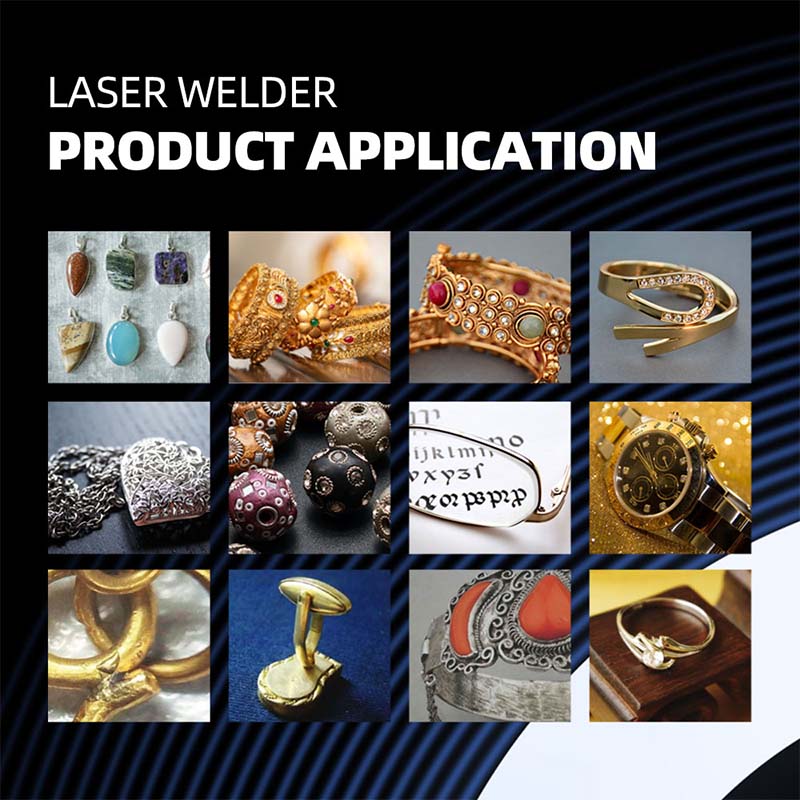

The laser welding for jewelry repair is suitable for a wide range of metals and alloy materials, such as gold, silver, platinum, stainless steel and titanium. It can also be used for denture filling grit and welding processing of tiny devices. Laser welding is widely used in the jewelry industry because of its high speed, high precision and convenience. It can fill tiny defects or voids in jewelry and enhance the overall quality and appearance of the jewelry. In addition, the technology can also repair platinum or gold claw settings by repairing, reinforcing or reconnecting the metal claws through fine soldering to ensure that the stones are firmly embedded in the jewelry. For bezel repair or reconstruction, jewelry laser welder can also give jewelry a new look.

What Can a Laser Welding Machine do in a Jewelry Store?

What is laser welding jewelry? Laser welding jewelry is a technique used in the jewelry industry to join metal pieces together. It involves the use of a laser beam to precisely melt and fuse metals, creating a strong and durable bond. The advantages of laser welding in jewelry include its precision, ability to work on various metals, and suitability for repairing or modifying intricate pieces. It is commonly used for tasks such as resizing rings, fixing prongs, and assembling complex designs.

Laser Welding for Jewelry Repair

Jewelry laser welding machines are primarily used for filling hole, spot welding of sand eyes, and repairing gold and silver jewelry. The laser spot welding process is a type of heat conduction, where the laser radiates and heats the surface of the workpiece. The surface heat then diffuses internally through heat conduction, and by controlling parameters such as the width, energy, peak power, and repetition frequency of the laser pulses, the workpiece melts, forming a specific molten pool. Due to its unique advantages, it has been successfully applied in the processing of gold and silver jewelry, as well as the welding of micro and small parts.

Adjusting Jewelry Size

Using a jewelry laser welding machine, rings can be easily adjusted to a slightly smaller or larger size.

Re-tilting Prongs and Repairing Settings

Prongs may become loose and often lose their grip on the tip of gemstones in rings. A jewelry laser welding machine can precisely locate the issues in the prongs and help them securely hold onto the gemstones. It can also assist in repairing the setting of ring prongs.

Reassembling Damaged Jewelry

Necklaces, bracelets, earrings, and other jewelry pieces can be easily repaired and reassembled. Whether due to wear, breakage, or other damage, the laser welding machine can finely and reliably restore jewelry, giving it a renewed appearance.

Custom Jewelries Design

Laser welding in the jewelry industry can achieve custom designs or modifying jewelry becomes easy. This allows for meeting customer requirements, whether it’s altering design patterns, adding decorative elements, or adjusting shapes.

Laser Welding for Jewellry Design

The use of laser technology in cutting raw diamonds allows for minimal loss and avoids the problem of chipping, providing a reliable basis for jewelry making. With the new setting method of the laser welding machine, the cut stone can be accurately embedded between two thin slices. This not only ensures a precise setting position, but also leaves the back of the stone free, opening up more possibilities for subsequent filigree decoration and transparent jewelry design.

Such an innovation not only reduces complexity in the production process, but also brings greater flexibility in terms of design. The entire jewelry design becomes simpler and designers are able to realize their creative ideas more quickly and produce unique and sophisticated jewelry pieces in a short period of time.

With a jewelry laser welding system, not only can you repair eyeglasses quickly and easily, but you can also work with a variety of metals, including titanium. This offers eyewear repair studios more profitability possibilities while improving the quality and efficiency of their services.

Jewelry laser welding machines are able to weld a wide range of metals including gold, silver, platinum, and titanium, and can handle delicate materials such as gemstones. In addition to welding, these machines can be used for repairing, engraving, marking, cutting, and shaping jewelry, providing a diverse range of process applications and making them an important tool for manufacturing and customizing jewelry.

Why Should Jewelers Invest in a Laser Welding Machine?

Jewelry laser spot welding machine is widely used because of its high welding speed, low distortion, and the lack of need for orthopedics and cleaning after welding. Laser welding technology has made it easier to create jewelry styles with special structures, avoiding problems that were difficult to accomplish or failed to meet quality standards in the past compared to traditional welding techniques. The jewelry manufacturing industry typically uses lower power laser welding machines that are safe, compact and easy to move around.

Maintaining the value of the jewelry

The value and quality of the jewelry is effectively safeguarded due to the low thermal damage caused by soldering.

High-precision machining

Accurate positioning during the soldering process ensures that a high degree of accuracy is maintained during the setting, while the surrounding jewelry is not damaged. The quality of the welded joints is excellent, presenting a beautiful appearance and leaving few traces after welding.

Small joints and fine

The advantages of laser welding machines are reflected in the small joints and the environmentally friendly meticulousness of the welds, which helps to achieve high-quality results.

Flexible adjustment of parameters

Laser welding parameters can be adjusted over a wide range. During the welding process, the welding dimensions can be adjusted at will to achieve a variety of welding results.

Precise positioning and small heat-affected zone

Especially suitable for small jewelry, the laser welding machine is able to accurately position the weld and at the same time, the heat-affected zone is small, which maintains the precision and detail of the jewelry.

High speed and automation

Realize high speed welding and automation, through computer control and digital adjustment, to ensure high precision processing and more delicate details.

Seamless welding without external force

Seamless welding is realized by laser welding machine without external force, which improves the stability of welding.

Highly concentrated energy

Highly concentrated energy, no need for additional consumables, the toughness after welding is comparable to that of the parent material, which ensures welding strength and quality.

Multi-material application

The current laser waveform is adjustable, applicable to a variety of materials, to ensure that the welding effect reaches a satisfactory level. These advantages make jewelry laser welding an efficient, precise and environmentally friendly processing technology.

Jewelry Laser Welding Machine Parameter Setting

– Laser Power

The appropriate power is selected according to the requirements of the welding material and the welding position. Typically, laser power for metal welding ranges from 40-300 watts. It is necessary to select the appropriate laser power and focal length. In general, the thinner the welding material, the less power and focal length is required.

– Pulse Frequency

Adjusts the number of pulses emitted by the laser beam in one second. Typically, the pulse frequency for welding metals ranges from 1-50 Hz. In general, materials with lower melting points require higher frequency laser pulses.

– Pulse Width

Adjusts the duration of each pulse of the laser beam. Typically, the pulse width for welding metals ranges from 0.1 to 20 milliseconds.

– Spot Size

Adjusts the focal spot size of the laser beam to accommodate different sized welding areas. Adjust the laser spot size and offset according to the shape and density of the weld joint to ensure a strong and beautiful weld joint.

Different jewelry materials and metal types may require different welding parameters. Therefore, it is best to refer to the instruction manual of the corresponding welding machine or go through training on the use of the machine and equipment, and make appropriate parameter adjustments and optimization in practice before carrying out the welding operation.

What is the Best Laser Welder for Jewelry?

Shenzhen Dapeng Laser Technology Co., Ltd. is a high-tech enterprise established in Shenzhen in 2011. The company’s business scope includes the research, development, manufacturing, and sales of industrial laser equipment. The main products of the company include:

1. Jewelry Laser Welding Machine: Specifically designed for the welding of gold and silver jewelry, this laser equipment achieves high-precision and efficient welding through laser technology. Jewelers can utilize this equipment to create intricate designs and securely bond precious metal components.

2. Handheld Laser Welding Machine: A portable laser welding device that can be widely used in multiple industries(Including soldering of electronic components, printed circuit boards, welding of metal materials, kitchen utensils, sinks, door handles, sheet metal fabrication, etc.), providing precise and reliable welding solutions. This device provides on-the-go welding solutions, enabling operators to achieve precision and reliability in their welding tasks across diverse materials and components.

3. Metal Laser Welding Machine: Laser equipment used for welding metal materials, with efficient and highly accurate welding capabilities, widely applied in the field of metal processing. Its applications span a wide range of metalworking processes, including fabrication, construction, and manufacturing of metal components for machinery and infrastructure.

4. Alumina Laser Welding Machine: Uniquely crafted for specialized applications, the alumina laser welding machine is designed to meet the high-precision welding needs of industries working with alumina materials. It finds essential use in fields such as ceramics and electronic components manufacturing.

5. YAG Laser Spot Welding Machine: Spot welding equipment using YAG laser technology, suitable for tiny spot welding of both metal and non-metal materials. Its applications extend to industries requiring micro-scale welding, such as electronics, medical devices, and microelectronics manufacturing.

6. Power Battery Welding Machine: A laser welding system designed specifically for the production of power batteries, offering efficient and high-quality welding solutions. The machine ensures the efficient and high-quality welding of battery components, contributing to the reliability and performance of power storage devices in the rapidly evolving electric vehicle and electronics industries.

Additionally, we also provide non-standard automation solutions. According to customer requirements, customized designs and integrated automation solutions are offered. More than 300 people of expert technical team makes the laser equipment produced by Dapeng Laser at the advanced level in terms of industry technology, to meet the needs of modern production for efficient, stable and reliable precision processing. The company aims to provide customers with high-quality laser welding equipment.

Customized Laser Welding Equipment Provided by Dapeng Laser

Free sampling: We provide free sampling service so that customers can test and evaluate before confirming the quality and effect.

Dedicated follow-up: Our team will keep in close contact with our customers and follow up the progress of the project throughout the process to ensure that questions are answered and needs are met in a timely manner.

Delivery and package installation: We not only provide delivery service, but also include installation service. Our professional staff will personally go to the customer’s designated location to install and ensure that the product is in good condition.

Instruction and training: In order to ensure that our customers can use our laser welding services correctly and flexibly, we provide detailed instruction and training to help customers’ better master the technical operation.

Free Maintenance: We provide free maintenance service to ensure that the products remain in good condition during normal use. Customers can contact us at any time to solve any problems.

Perfect After-Sales Service: We emphasize on after-sales service to provide customers with comprehensive support. Whether it is technical support or after-sales consultation, we will try our best to meet the needs of customers.

Support Return to Factory: If any problem occurs during the product warranty period, we provide return to factory for repair service. Customers just need to send the products to our repair center, we will be responsible for repairing and returning them as soon as possible.

200W Compact Mini Portable Jewelry Laser Welding Machine

Laser power: 200W

Laser wavelength: 1064nm

Voltage: 220V 1 phase

Welding depth: 0.1-3mm

Pulse width: 0-20ms

Laser frequency: 0-50HZ

Spot adjustment range: 0.3-2.5mm

This is a lightweight and mini jewelry laser welding machine. The machine adopts high-quality YAG laser source, which is characterized by fast welding, small deformation, and small welding spot and small heat-affected zone. It shows good performance in welding gold, silver, platinum and other materials, which can greatly improve the welding efficiency of jewelry making. The pulse width, frequency and spot of this laser machine can be adjusted according to the need to realize a variety of welding performance.

This jewelry laser machine is widely used in many fields such as shopping mall parts, rings, pendants, bracelets, dentures, cell phone charger interfaces, hardware, watches, sporting goods, golf heads, and medical equipment and so on. It is especially suitable for titanium alloy jewelry, and can be used for gold and silver jewelry to fill holes, spot weld seam lines, inlays and other welding processes.

Summary:

Jewelry laser soldering machines have become a powerful assistant in the field of jewelry restoration and processing because of their efficiency and accuracy. The benefits of laser welding jewelry mentioned in this article: it can help restorers to complete the restoration of jewelry quickly and accurately, improving work efficiency and customer satisfaction. Secondly, for jewelry designers, jewelry welding machines can provide more creative possibilities and help designers achieve more unique and exquisite designs.