Laser cutters have become essential tools across a wide range of industries, offering precision and versatility for cutting various materials. In this article, we will explore the various different types of laser cutters, key features, and the industries they serve.

Laser cutting is a technology that uses a high-energy laser beam for material processing. In this process, the laser light generated by the laser source is directed and focused by a lens into a fine, high-energy density beam, which irradiates the surface of the material, rapidly heating it to its melting point or causing it to vaporize. At the same time, high-pressure gas coaxial with the laser beam helps remove the molten or vaporized material. A numerical control (NC) system adjusts the laser’s output and mechanical movement, allowing the beam to move relative to the material, cutting along a predetermined path to achieve the designed shape. Laser cutting can be used for cutting both metal and non-metal materials.

Laser cutting equipment is primarily an integration of mechanical, optical, and electrical components. The entire system mainly consists of three parts: the machine bed, the laser and external optics, and the CNC system with the control console.

Machine Bed: This part of the laser cutting machine handles the mechanical movements along the X, Y, and Z axes, including the cutting worktable. It holds the workpiece and allows precise movement according to the control program, usually driven by servo motors.

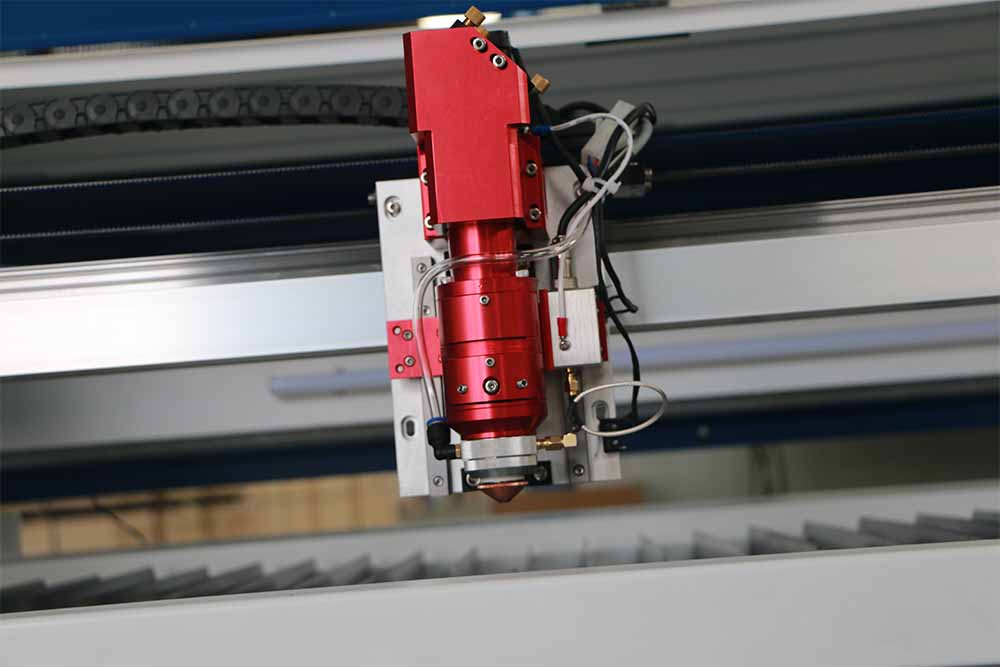

Laser Source and External Optics: The laser generates the cutting beam, while the external optics guide the laser to the surface of the workpiece.

CNC System and Control Console: This system is responsible for programming the cutting path and controlling the machines X, Y, and Z axis movements, as well as managing the laser output power and cutting parameter settings.

In addition to the three main components, laser cutting system is integrated with auxiliary systems such as a voltage stabilizer, chiller unit, gas cylinders, air compressor, air tank, cooling dryer, filters, exhaust dust collector, and slag discharge machine. Together, these elements form a complete fiber laser cutting system.

What Are the Different Types of Laser Cutters?

There are various types of CNC laser cutting machine, each with different classification standards.

By laser source, laser cutting machines can be divided into fiber laser cutting machines and CO2 laser cutting machines.

Fiber Laser Cutting Machines: These are the most widely used laser cutting machines in the market today. They use a fiber laser as the light source, enabling fast and precise cutting of various materials due to their high-quality beam and high energy density. Fiber laser cutters are commonly used for cutting, drilling, and engraving metal sheets and tubes, excelling in cutting stainless steel, carbon steel, and aluminum alloys.

CO2 Laser Cutting Machines: These machines use CO2 gas as the working medium and are mainly suited for cutting non-metal materials such as wood, acrylic, fabric, and leather. CO2 laser cutting machines offer high cutting speed, efficiency, and low operational costs, making them popular in industries like furniture manufacturing, advertising, and textiles.

| Fiber Laser Cutting Machine | CO2 Laser Cutting Machine | |

| Pros. | High efficiency and energy saving: high photoelectric conversion efficiency, low energy consumption and low running cost.Fast speed: faster than CO2 fiber laser cutting machine, especially suitable for thin metal plate cutting.Low maintenance cost: basically maintenance-free, long service life. | Versatile: can cut most non-metals with good cutting performance and smooth edges.Fast speed: CO2 laser cutters can cut thin sheets of material quickly.High precision: they can make precise cuts and are suitable for complex pattern processing. |

| Cons. | Thick plate cutting is limited: the speed is slower when cutting relatively thick plates.Higher cost: its initial investment is relatively high.Not suitable for non-metal cutting: its performance in non-metal cutting is not as good as CO2 laser cutting machine. | High energy consumption: low photoelectric conversion efficiency and high energy consumption.High maintenance cost: the maintenance cost of the laser and optical system is high.Unsuitable for cutting metals: they are not good at cutting metals, especially highly reflective metals. |

Ultra-fast laser cutting machine is a kind of laser cutting machine which adopts ultra-fast laser as the light source. It is characterized by short pulse width, high peak power, etc., which enables fine processing and high-quality cutting of materials. Ultra-fast laser cutting machine is mainly used in microelectronics manufacturing, optoelectronic devices, biomedicine and other fields to carry out fine processing and micro-Nano processing of materials.

By laser output power, laser cutting machines are classified into high-power, medium-power, and low-power machines. The power range varies based on the type of laser. In the sheet metal processing industry, high-power fiber laser cutting machines are predominantly used. In contrast, medium-power laser engraving and cutting machines are more commonly employed in the engraving field.

Based on typical cutting speeds, we recommend the following laser power for different materials:

1000W: Cuts carbon steel up to 12 mm, stainless steel up to 5 mm, and aluminum up to 3 mm.

1500W: Cuts carbon steel up to 14 mm, stainless steel up to 6 mm, and aluminum up to 5 mm.

2000W: Cuts carbon steel up to 18 mm, stainless steel up to 8 mm, and aluminum up to 8 mm.

12000W: Cuts carbon steel up to 25 mm, stainless steel up to 40 mm, and aluminum up to 35 mm.

By workbench size, laser cutting machines can be categorized into standard-format and large-format machines. Standard-format machines typically have dimensions such as 3000mm x 1500mm, 4000mm x 2000mm, 6000mm x 2000mm, and 12000mm x 2500mm. The two numbers represent the cutting widths in the X-axis and Y-axis directions. Before purchasing, it is essential to measure and plan the working area for the laser cutting machine.

For example, the Dapeng Laser 3015F model has a cutting area of 3000mm x 1500mm, classifying it as a standard-format laser cutting machine. In contrast, the SH12025F model has a cutting area of 12000mm x 2500mm, categorizing it as a large-format laser cutting machine.

The laser tube cutting machine is a precision device specifically designed for cutting metal pipes and other cylindrical materials. When referring to the working table sizes of such machines, model codes like “6035” and “6060” often indicate the processing range of the equipment for pipes.

For example, 6035 means that this model can process a maximum pipe length of 6000 mm (i.e., 6 meters) and a maximum diameter of 350 mm.

By cutting geometry, laser cutting machines can be classified into sheet laser cutting machines, robotic laser cutting machines, and 3D five-axis laser cutting machines. Sheet laser cutting machines are designed for cutting and processing 2D flat sheets, while robotic laser cutting machines and three-dimensional laser cutting machines can cut and engrave three-dimensional sheets and pipes.

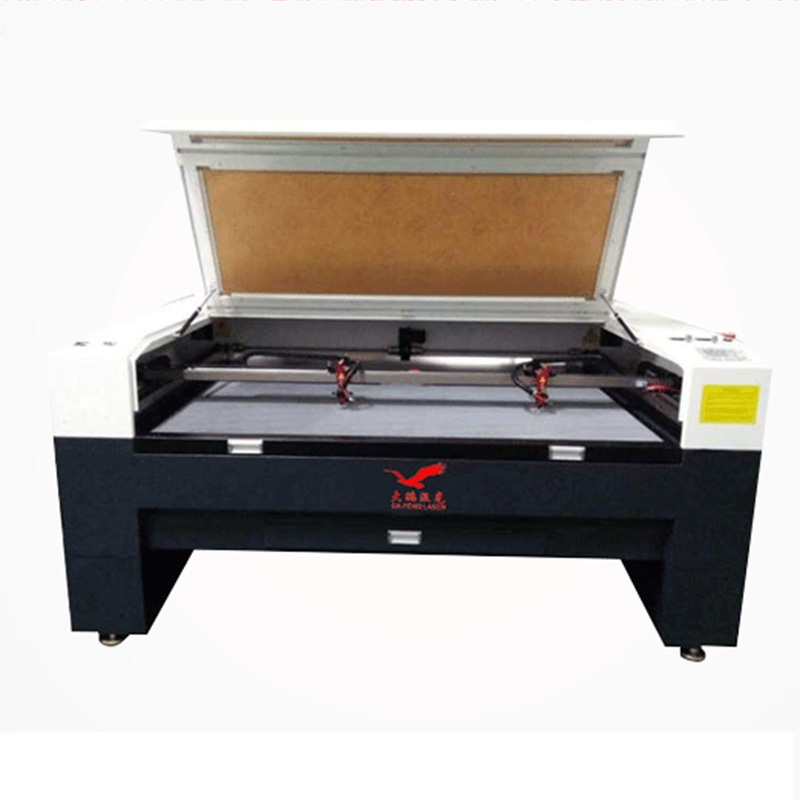

By the structure of the worktable, laser cutting cutters can be categorized into open single table laser cutting machines and exchange table laser cutting machines.

Open Type Single Table Laser Cutting Machine: These machines feature a single fixed cutting worktable, making them suitable for small batch production where material changes are frequent, especially for loading and unloading large or heavy workpieces. They are widely adopted due to their open structure, which facilitates easy material handling and offers lower costs, making them popular among small and medium-sized manufacturing enterprises.

Exchange Table Laser Cutting Machines: These machines have two worktables that can be alternately used, ideal for mass production and capable of achieving very high production efficiency. While one worktable is engaged in cutting, the other can handle loading and unloading, significantly reducing standby time and allowing for seamless integration with automated loading and unloading systems. However, the dual-table structure is more complex, resulting in higher operating and maintenance costs. The exchange table design also facilitates easy material handling.

Both single-table and exchange table laser cutter can be equipped with fully enclosed covers, along with laser safety glass and fume extraction systems, to isolate laser hazards from human exposure and protect the environment.

Advantages of Laser Cutting

High Precision and Quality Cutting: Laser cutting achieves exceptionally high precision, making it ideal for producing intricate designs and fine details. The cut edges are usually very smooth and nearly burr-free, reducing the need for subsequent finishing processes.

Reduced Material Waste and Increased Efficiency: Thanks to its high precision, laser cutting allows for more effective use of raw materials, minimizing waste. Additionally, the fast cutting speed is particularly advantageous for mass production, helping to shorten overall production cycles and improve work efficiency.

Wide Material Compatibility: Laser cutting is not limited to metal materials; it can also process various non-metal materials, including plastics, wood, and glass. This versatility enhances the applicability of laser cutting technology across different industries, broadening its range of applications.

DPLaser Fiber Metal Laser Cutting Machine

The fiber laser cutting machine system can process a variety of metal types, playing a significant role in industrial and commercial applications. It is widely used in industries such as sheet metal processing, electronics, electrical appliances, subway components, automotive parts, hardware machinery, precision components, metallurgical equipment, elevators, craft gifts, decorative items, advertising, and medical devices.

Fiber Laser: Utilizes top-brand lasers for stable and reliable power, ensuring excellent performance.

High Efficiency: Cutting speed is twice that of standard laser cutting machines.

AC Servo Motor Drive System: The system employs gear and rack transmission with linear guide rails, guaranteeing high speed, high precision, and high reliability.

High Precision: Repeat positioning accuracy is controlled within ±0.02 mm.

Lower Power Consumption: Power consumption is reduced by 20%-30% compared to conventional laser cutting machines.

Maintenance-Free: Fiber laser cutting machines do not require mirrors, saving considerable time during optical path adjustments. The laser source has a longer lifespan and requires no maintenance during operation.

Enhanced Durability: The machine frame undergoes annealing treatment to enhance shock resistance (non-annealed machines may deform), resulting in improved precision and stability for 4~5 years.

Open Type Fiber Laser Cutting Machines Price

The price of open type fiber laser cutting machines is influenced by various factors, such as power output, brand, workbench size, control system and additional features. Therefore, it may not be possible to provide an exact price at this time. However, we can estimate price ranges based on different power outputs:

Low Power (1-3 kW): Prices typically range from $10,000 to $60,000.

Medium Power (6-10 kW): Prices generally fall between $60,000 and $100,000.

High Power: Open-frame fiber laser cutting machines can exceed $200,000.

If you are interested in detailed pricing for metal fiber laser cutting machines, please leave us a message.

For inquiries regarding the quote of fiber laser cutting system or if you have questions about the different types of CNC laser cutting machine mentioned above, please contact us via phone, email, or online chat. Our professional laser experts are ready to assist you in customizing equipment that meets your production needs.

In conclusion, understanding the different types of laser cutters is essential for selecting the right equipment for your specific cutting needs. Which is best laser cutting machine? Whether you require a sheet laser cutting machine, robotic laser cutter, or a 3D five-axis system, each offers unique features for various applications. By choosing the right laser cutting machine, you can enhance efficiency and precision in your production processes. Explore our range of laser cutting machines to find the perfect solution for your industrial requirements and elevate your cutting capabilities.