What are fiber lasers used for? In the manufacturing industry, fiber lasers can be used in processes such as material cutting, drilling, welding, and more. The high energy density and superior beam quality of fiber lasers enable the precise processing of various materials, including metals and non-metals, in cutting, drilling, welding, marking, and other machining processes. This enhances work efficiency and processing quality.

Fiber Laser Pros and Cons

Beam Quality: Fiber laser cutting machines possess excellent beam quality, with a smaller focused spot, enabling finer cutting lines and achieving higher-quality processing.

Cutting Speed and Processing Efficiency: The fiber laser generator utilizes fiber laser technology, enabling high-power output. The high-power laser beam provides stronger penetration and processing effects. Compared to CO2 laser cutting machines, the cutting speed and efficiency of fiber laser cutting machines are twice that of CO2 machines with equivalent power.

Adjustable Frequency: The frequency of this laser generator can be adjusted, allowing users to choose the appropriate working frequency based on different requirements. This feature provides greater flexibility for fiber laser generators in various applications.

Wide Applications: Fiber laser generators can be widely applied in material processing, laser marking, laser cutting, and other fields. Whether it’s metal or non-metal materials, they can be processed using laser equipment.

Efficiency: Fiber laser generators use advanced optical design and optimized control systems, ensuring high efficiency with low energy consumption. The overall power consumption of the fiber laser cutting machine is only 20-30% of that of CO2 laser cutting machines, resulting in lower operating costs relative to CO2 machines.

Ease of Operation: The equipment adopts a user-friendly interface and an intelligent control system, making the operation simpler and more convenient. Even beginners or non-professionals can quickly become familiar with and operate the equipment.

Fiber lasers come with drawbacks, including a higher initial cost, potential complexity in maintenance and repairs, limitations in cutting thicker materials, inefficiency with certain materials, complex beam delivery systems requiring careful alignment, and the impact of fiber quality on overall efficiency and reliability. Despite these considerations, their numerous advantages make them a valuable tool in various industrial applications.

Fiber Lasers with Different Powers

Low-Power Fiber Laser

With an output power of less than 100W, it is primarily used for laser marking, drilling, precision processing, and metal engraving.

Medium-Power Fiber Laser

With an output power of up to 1.5kW, it is mainly applied to the welding and cutting of metal materials, as well as the refurbishment of metal surfaces.

High-Power Fiber Laser

With an output power exceeding 1.5kW, it is mainly used for cutting thick metal sheets, three-dimensional processing of special materials, and similar applications.

What is the Difference between Fiber Laser and Co2 Laser?

Fiber Laser and CO2 Laser are two distinct types of laser cutting devices, exhibiting notable differences in cutting materials, power, cutting quality, pricing, and primary applications.

Cutting Materials:

– Fiber Laser: Fiber lasers are typically suitable for cutting metal materials such as steel, aluminum, and copper. They are particularly adept at high-speed cutting of thin metal materials and are well-suited for sizes of 20 millimeters or smaller.

– CO2 Laser: CO2 lasers are more suited for non-metal materials like wood, plastic, glass, ceramics, and organic materials. They excel in cutting non-metal materials.

Beam Quality:

– Fiber Laser: Fiber lasers typically have excellent beam quality, which results in a smaller, more focused laser spot for precise material processing.

– CO2 Laser: CO2 lasers have a larger beam spot and are better suited for applications where beam quality is not critical.

Power:

– Fiber Laser: Fiber lasers typically offer higher power, suitable for high-speed and deep cutting tasks. They generally have a power range of 1 kW to 15 kW.

– CO2 Laser: CO2 lasers typically operate within a lower power range, usually between 25 W and 6 kW, used for cutting and engraving tasks. Fiber laser cutting machines are 3 to 5 times faster than CO2 laser cutting machines with equivalent power.

Cutting Quality:

– Fiber Laser: Fiber lasers usually provide higher cutting quality, with smoother edge quality and higher precision.

– CO2 Laser: CO2 lasers perform well in cutting non-metal materials, but they may not match fiber lasers in metal cutting.

Price:

– Fiber Laser: Fiber lasers generally come with a higher initial investment cost. However, they are often considered cost-effective in the long run due to lower maintenance requirements resulting from their solid-state construction and longer operating lifetimes.

– CO2 Laser: CO2 lasers typically have a lower initial investment cost, but they may incur higher maintenance costs due to the complexity of gas-filled tubes and the need for periodic replenishment or adjustment of the gas mixture.

CO2 lasers have efficiencies of around 5%~10%, which means that they consume 10~20 times more power than they emit in the form of a laser. This compares poorly with fiber lasers, which typically offer efficiencies in excess of 90%, and means that while CO2 has a low initial investment, the later operational investment is significant.

Applications:

– Fiber Laser: Fiber lasers are often used for cutting, welding, engraving, and marking materials like metals, plastics, and ceramics. They are particularly suitable for high-precision and high-speed applications.

– CO2 Laser: CO2 lasers are commonly used for cutting, engraving, and marking materials like wood, acrylic, paper, and textiles. They are also used in industrial applications and medical procedures.

| Optical Fiber Laser | CO2 Laser Source |

| Benefits of Fiber Laser High Efficiency: Fiber lasers are typically highly efficient, effectively converting input energy into laser output.Excellent Beam Quality: Fiber lasers generally exhibit excellent beam quality, producing small and focused laser spots suitable for high-precision material processing.Long Lifespan and Low Maintenance: Fiber lasers usually have a longer lifespan and require less maintenance since they do not rely on gas filling. | Benefits of CO2 Laser Widely Applicable to Non-Metallic Materials: CO2 lasers generate laser wavelengths around 10.6 micrometers, suitable for cutting, engraving, and marking many non-metal materials such as wood, acrylic, paper, and fabric.Lower Costs: Compared to some high-power laser systems, CO2 lasers typically have lower costs, making them a viable choice for many small and medium-sized enterprises. |

| Processing Thick Materials: Fiber lasers present some challenges and limitations when processing thicker materials.Higher Costs: Fiber lasers generally have higher costs than CO2 lasers, especially in high-power applications. | Lower Efficiency: CO2 lasers typically have lower efficiency compared to other types of lasers such as fiber lasers, meaning they consume more energy.Complex Gas Filling: CO2 lasers require a stable gas mixture, and gas filling and maintenance are relatively complex.Larger Beam Spot: The beam spot of CO2 lasers is larger, suitable for certain applications but not ideal for tasks requiring high precision. |

Fiber Laser Applications for Manufacturing

According to the operational mode, fiber lasers have two most commonly used types: continuous-wave lasers and pulsed lasers. CW lasers emit a continuous beam with a peak power of 120 kW. They are used for cutting, welding, brazing, and drilling. Pulsed lasers can be further classified into nanosecond, picosecond, and femtosecond pulsed lasers.

Nanosecond laser: nanosecond pulsed lasers typically have pulse widths in the nanosecond range (10^-9 seconds), making their pulses relatively longer. These lasers are widely used in various industrial applications, including scribing, etching, and drilling, surface treatment, hardening, and marking.

Picosecond laser: picosecond pulsed lasers have pulse widths in the picosecond range (10^-12 seconds), shorter than the pulses of nanosecond lasers. This makes them suitable for finer processing tasks such as micro fabrication, cutting of semiconductors, sapphires, and glass.

Femtosecond lasers: femtosecond pulsed lasers have pulse widths in the femtosecond range (10^-15 seconds), among the shortest pulses. They are highly valuable in precision material processing, ophthalmic surgery, and fields involving ultra-short pulse lasers.

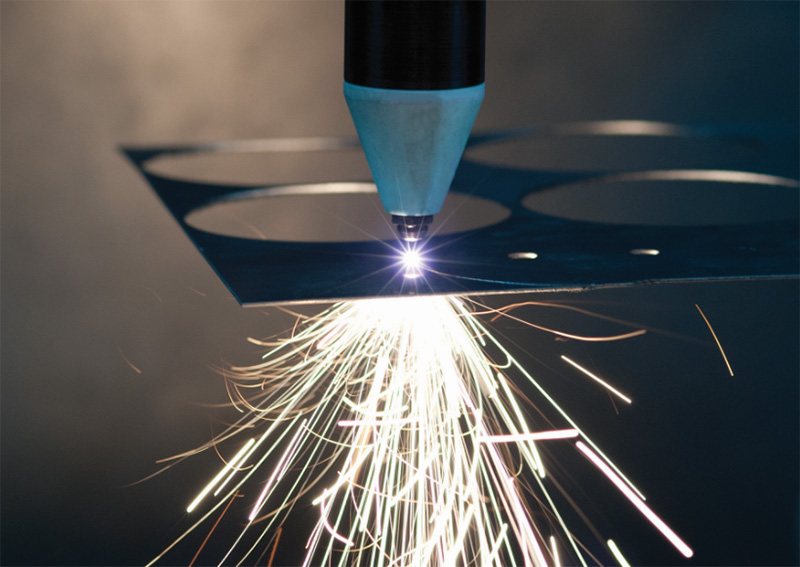

Industrial fiber Laser Cutting Machine

Fiber laser cutting utilizes a fiber optic beam to transmit laser energy to the cutting head for the cutting process. With high photoelectric conversion efficiency and low power consumption, it is suitable for cutting stainless steel and carbon steel plates. It offers faster cutting speeds for thin sheets compared to other cutting machines. The advantages of fiber laser cutting machines include high speed, efficiency, good cutting surface quality, and the ability to cut thicker materials. It is suitable for high-precision processing, especially for thin sheets up to 12mm. When cutting materials like carbon steel, stainless steel, pure aluminum, brass, and other highly reflective materials, it exhibits faster cutting speeds than traditional CO2 laser cutting machines. The fiber laser beam achieves a smaller spot diameter, allowing for faster processing speeds even with thicker materials, significantly reducing workpiece tolerances.

Fiber laser cutter is suitable for high speed cutting of metal materials, carbon dioxide laser cutter is suitable for fast cutting of non-metallic materials, and YAG solid state laser cutter is suitable for cutting processes that require high precision.

Fiber Laser Cleaning

Continuous fiber laser cleaning employs a continuous laser light source, typically a continuous-wave (CW) laser, emitting a stable continuous laser beam. This method is commonly used for surfaces requiring continuous and uniform cleaning, such as the removal of oil, dirt, oxides, and other contaminants.

Pulsed Fiber Laser Cleaning utilizes a pulsed laser light source, usually a pulsed laser, emitting high-energy light pulses. Pulsed Fiber Laser Cleaning is typically employed in applications that demand high-energy cleaning and have strict requirements for material surface quality, such as removing welding residues, coating removal, and cleaning intricate components.

In industries like large-scale shipping, automotive, and aerospace, high-power laser cleaning equipment is predominantly based on pulsed fiber lasers. Continuous Fiber Laser Cleaning is suitable for relatively straightforward cleaning tasks, while Pulsed Fiber Laser Cleaning is applicable to tasks that require high energy and precision cleaning.

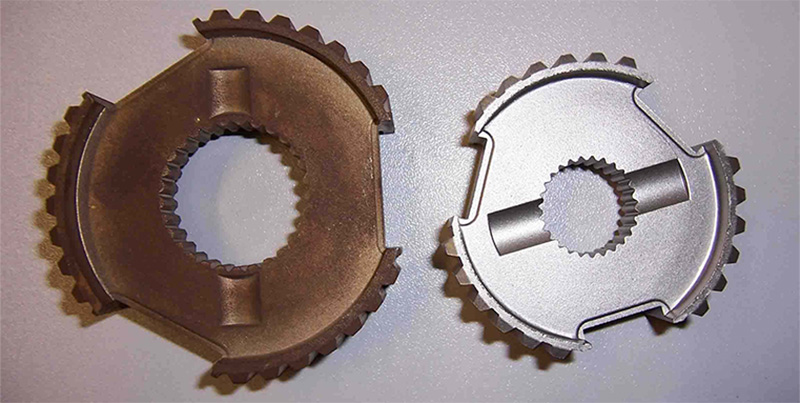

Fiber Laser Application in Marking

Fiber laser marking excels in high-contrast marking tasks and is particularly suitable for the processing of metallic materials. They are unique in their ability to produce very small focal diameters with 100 times higher laser intensity than CO2 laser systems. This feature makes fiber lasers ideal for permanent marking on metallic materials, including information such as serial numbers, bar codes and data matrices.

The advantages of fiber laser marking are its high accuracy, high speed, low maintenance and long life, making it an ideal tool for clear, durable marking and traceability in a variety of industries. These applications not only help improve production efficiency, but also enhance brand personalization of products, parts traceability, and quality management.

Conclusion:

What does a fiber laser do? From efficient cutting and cleaning to precise marking, fiber lasers have showcased their unique advantages in manufacturing, materials processing, and various other fields. Whether applied in high-speed, high-precision metal cutting machines or delivering clear and durable marks in laser engraving, fiber laser technology has made significant contributions to the industrial landscape. In industrial, fiber laser technology has emerged as a remarkable innovation, distinguished by its outstanding performance and diverse range of applications.