Ultrafast laser cutting technology has rapidly advanced, offering exceptional precision and speed for micron- and even nanoscale processing on various materials, including quartz glass. Its applications span a wide range of industries, from microelectronics to biomedical engineering, where picosecond and femtosecond laser technology play a crucial role. The glass laser micro cutting machine not only enhances processing efficiency but also significantly expands the possibilities of material machining, bringing revolutionary advancements to the field of precision manufacturing.

Types of Glass Laser Micromachining

1. Picosecond Laser Cutting

Picosecond laser cutting machines use ultra-short picosecond laser pulses for precise cutting. The extremely short pulse duration, typically in the picosecond range (1 picosecond = 10^-12 seconds), allows for extremely high peak power while maintaining low average power. This minimizes the heat-affected zone (HAZ) and enables near-cold processing.

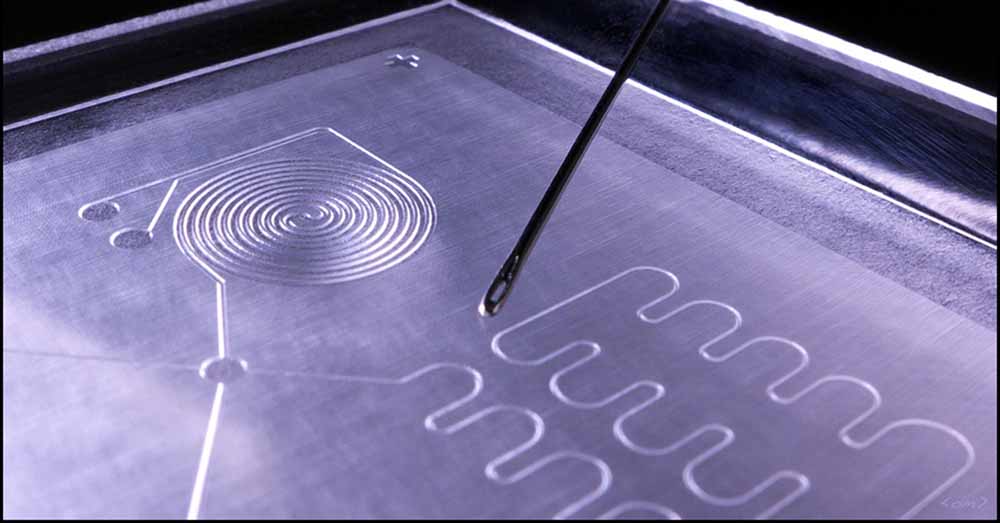

2. Laser Glass Drilling

Laser drilling removes glass material point by point by focusing pulsed energy. A galvanometer controls the laser focal point to scan along a predefined path at high speed, achieving efficient drilling. Using a bottom-up spiral processing approach, material is removed layer by layer from the bottom of the glass until complete penetration is achieved. This method is suitable for photovoltaic glass, electronic glass, microcrystalline glass, and glass tubes. It can process hole diameters from 0 to 60mm and glass thicknesses from 0 to 12mm, with an edge chipping of less than 250μm, invisible to the eyes.

3. Ultrafast Laser Glass Marking

When the laser energy density exceeds the damage threshold of glass, it can engrave patterns, text, QR codes, and other information on the glass surface, resulting in a frosted gray marking effect. This technique is widely used for logos, anti-counterfeiting codes, and similar applications.

4. Ultrafast Laser Glass Black Marking

By utilizing the high-temperature and high-pressure characteristics of ultrafast lasers, this process ablates the stainless steel material beneath the glass, causing carbon ink particles to adhere to the glass surface. This creates a high-contrast black marking, making it ideal for high-end electronics and industrial applications.

5. Ultrafast Laser Glass Color Marking

Ultrafast lasers alter the refractive index inside the glass to form a micro-Nano grating structure, creating colorful markings within transparent glass. This technique is widely applied in artistic decorations, premium signage, and optical components.

✅ Cold Processing: No heat-affected zone, reducing the risk of cracks

✅ High Precision: Micron-level processing accuracy with smooth, burr-free edges

✅ Wide Material Compatibility: Supports various glass types, including soda-lime glass, borosilicate glass, quartz glass, and sapphire

✅ High Efficiency & Stability: Non-contact processing suitable for mass production

Application of Glass Laser Cutting and Drilling Machine for Special-Shaped Hole

In the process of drilling special-shaped holes in glass, picosecond laser cutting machines have become a key industry choice due to their high precision and efficiency. Among them, the Dapeng Laser picosecond laser cutting system stands out with its excellent performance, providing high-quality solutions for glass drilling and cutting.

Complex Cutting Edges with Micron-Level Precision

Picosecond laser technology enables micron-level precision machining, allowing for accurate processing of circular, square, or complex curved shapes with exceptional detail.

1. High-Precision Cutting to Ensure Glass Quality

- The high energy density of picosecond laser pulses enables precise cutting while minimizing heat and vibration.

- Unlike traditional laser cutting, picosecond laser processing significantly reduces micro-cracks and edge defects, enhancing glass quality and reliability.

2. High-Efficiency Cutting to Reduce Production Costs

- The ultrashort pulse width of picosecond lasers allows for rapid material evaporation, minimizing energy loss and increasing cutting speed.

- Compared to conventional laser equipment, picosecond laser cutting machines greatly improve production efficiency and lower processing costs, creating new growth opportunities for the manufacturing industry.

3. Driving Innovation and Industry Development

The application of laser technology in glass cutting presents vast potential. In the future, more advanced and reliable picosecond laser systems will continue to drive technological advancements, optimizing manufacturing processes and offering superior solutions for the LCD display manufacturing industry and beyond.

Laser Micromachining System for Glass Cutting

Glass, as a brittle material and thin film, often faces challenges in traditional processing methods, such as breakage, edge chipping, uneven cutting paths, and surface damage. However, the application of picosecond and femtosecond laser cutting machines has brought significant breakthroughs in the glass manufacturing industry, greatly improving both processing quality and efficiency.

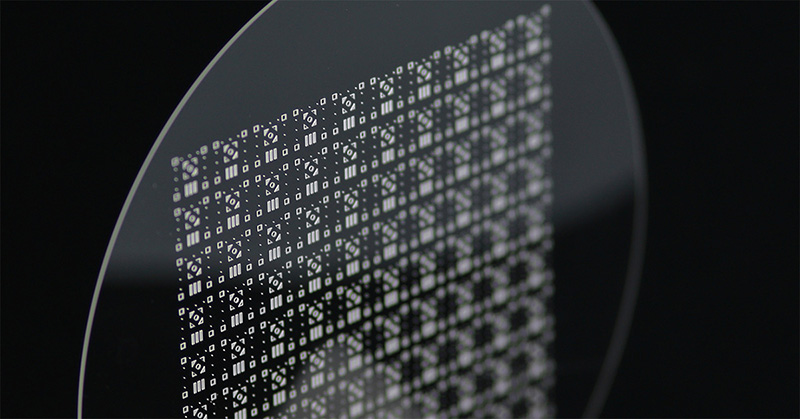

1. Precision Machining of LCD Glass Substrates

LCD glass substrates are ultra-thin specialty glass materials, with thicknesses as low as 0.4mm, and in some electronic applications, as thin as 0.05mm. As the core component of display panels, their quality directly affects the performance of LCD TVs, monitors, and other devices. Traditional processing methods often result in fractures, edge chipping, and micro cracks, reducing the final product yield.

By utilizing ultrafast laser micromachining systems, manufacturers achieve:

- High precision (error margin below 20μm)

- Fast cutting speeds

- Smooth, burr-free, and crack-free edges

This has made ultrafast laser cutting the mainstream technology for optoelectronic display glass substrate manufacturing.

2. High Aspect Ratio Microhole Machining in Quartz Glass

Microhole drilling (diameters below 300μm) is a critical process in micro device manufacturing, widely used in microfluidic devices, electronic packaging, and semiconductor applications, requiring extreme precision and quality.

Traditional processing techniques struggle to meet these demands, whereas femtosecond laser technology delivers exceptional results. For example:

- Drilling 72μm diameter holes with 1,824μm depth

- Achieving an impressive aspect ratio of 25.3:1

This enables high-precision manufacturing, providing optimal solutions for industries requiring micro-scale drilling.

3. Microhole Machining for Solar Photovoltaic Glass

Photovoltaic glass is a key component of solar panels, including front and back glass. Back glass is increasingly replacing traditional PVDF film to enhance fire resistance, waterproofing, and durability, while reducing potential-induced degradation (PID). Picosecond and femtosecond laser cutters can precisely machine various small hole shapes with high accuracy and stability, ensuring smooth hole walls. Compared to traditional methods, laser processing improves efficiency and eliminates the need for washing, grinding, or polishing, significantly reducing production costs.

4. Glass Coating on Metal Pipelines

Metal pipelines are widely used in energy, thermal, and material transport industries but are prone to corrosion, leading to economic losses and potential hazards. Laser cladding technology applies a dense glass coating on metal surfaces by using a high-energy laser to melt and fuse glass powder onto the substrate. This enhances wear resistance, corrosion resistance, heat resistance, and oxidation resistance, significantly extending the pipeline’s lifespan.

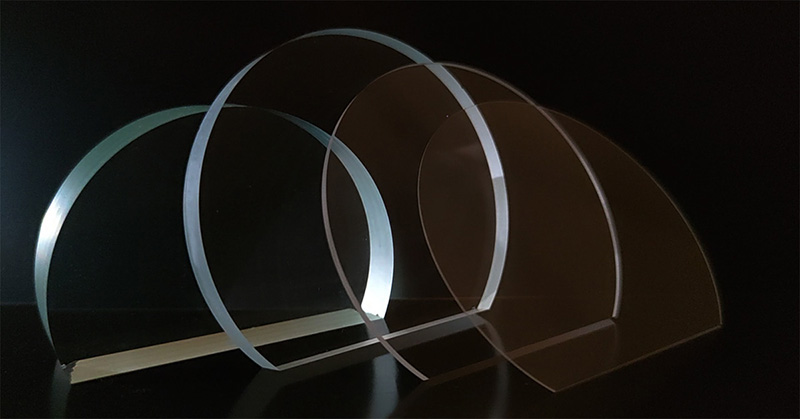

5. High-Precision Quartz Pendulum Processing

Quartz pendulums are critical components in quartz flex accelerometers used in aerospace, aviation, and inertial navigation systems. Due to their complex structure and extreme precision requirements, traditional processing methods struggle to meet standards. These components have thicknesses of only 0.66–0.76mm, with key features such as cantilever beams and triple-boss structures as thin as 20μm, and C-slot widths of just 0.3±0.1mm. Ultrafast laser machining ensures high precision and superior surface quality, providing reliable solutions for quartz accelerometer manufacturing.

6. Microstructure Fabrication on Glass Surfaces

Femtosecond laser processing enables the creation of microstructures (e.g., ridges, grooves) on glass surfaces for various applications:

- Solar panel cover glass: Reduces reflection loss, improving photovoltaic conversion efficiency.

- Optical components: Enhances image uniformity and clarity, improving optical performance.

- Microfluidic channels on glass: Facilitates fluid control for analytical chemistry, environmental monitoring, and biomedical research, such as simulating capillaries for blood or drug flow studies.

Infrared Picosecond Laser Glass Cutting Machine for Various Glass Materials

1. Compatible Glass Types

Soda Calcium Glass Cutting: Commonly used in construction, furniture, and home appliances.

Borosilicate Glass Cutting: Known for heat resistance and chemical stability, ideal for laboratory equipment and cookware.

Quartz Glass Cutting: High thermal resistance and optical transparency, making it perfect for semiconductor and optical component manufacturing.

Sapphire Glass Cutting: Used for smartphone sapphire covers, camera lens covers, and LED sapphire substrates.

LCD Glass Cutting: Supports cutting for special-shaped LCD screens, including rounded R/U/C corners.

Specialty Glass Cutting: Covers bulletproof glass, conductive glass, optical fiber, and other high-performance glass materials.

2. Cutting Capabilities

Borosilicate & Soda-Lime Glass: Cutting thickness 0.5–20mm, speed 50–1500mm/s.

Sapphire Glass: Cutting thickness 0.5mm, speed 70mm/s.

3. Cutting Thickness of Ultrafast Laser Glass Processing

The cutting capability of an infrared picosecond laser cutting machine depends on factors such as laser power, wavelength, pulse width, and the specific type of glass. Generally, the cutting thickness ranges from a few microns to several millimeters, as follows:

- Thin Glass (e.g., smartphone screen protectors): Easily cut down to tens of microns.

- Medium-Thickness Glass (e.g., standard window glass): Can be cut up to several millimeters.

- For thicker glass, cutting speed may decrease, and higher laser power is required. When selecting an infrared picosecond laser cutting machine, it is essential to consider production needs and glass material properties to choose the most suitable equipment model.

Picosecond Laser Glass Cutting Machines Manufacturer

As a leading manufacturer of picosecond laser glass cutting equipment, DPLaser is committed to providing customers with high-precision, high-efficiency, and multifunctional ultrafast laser cutting solutions. Our machines are widely used for processing various glass materials, including standard float glass, high-borosilicate glass, ultra-clear embossed glass, and transparent conductive oxide (TCO) coated glass, meeting the precision manufacturing needs of various industries.

Why Choose Our Ultrafast Laser Glass Cutting Machine

Ultrafast Laser Technology

Utilizing customized picosecond and femtosecond lasers combined with a proprietary beam-shaping cutting head, our ultrafast laser technology enables precise cutting and segmentation of various brittle materials. This ensures smooth, chip-free edges, with chipping as small as approximately 2 microns.

High Precision with No Thermal Impact

Our cutting process eliminates taper and gaps, with an extremely small heat-affected zone (HAZ). The processed edges are free of debris, burrs, or residues, perfectly meeting the requirements for high-precision glass cutting.

Versatile Applications

Our acrylic glass cutting machine is not limited to glass cutting. It also supports precision engraving, marking, drilling, milling, and forming, making it ideal for developing complex micro-scale products.

Wide Industry Applications

Our technology is extensively used in lens manufacturing, optical components, the medical industry, precision instrument lenses, smart wearable, glass watch dials, semiconductors, automotive rearview mirrors, the cosmetics industry, mirror cutting, and precision engraving and marking.

With extensive expertise in laser drilling, cutting, marking, and forming, Dapeng Laser ensures that every machine meets the highest precision and quality standards. Driven by customer needs, we provide customized solutions to help clients achieve efficient and precise manufacturing goals. In a word, as ultrafast laser micromachining continues to evolve, it is redefining the possibilities of precision glass cutting. With its high accuracy, minimal thermal impact, and ability to handle complex geometries, technologies like picosecond and femtosecond laser cutting are setting new standards across industries. Whether you need intricate micro-cutting, high-speed drilling, or delicate edge finishing, DP Laser’s infrared picosecond laser glass cutting machine offers cutting-edge solutions tailored to your manufacturing needs.