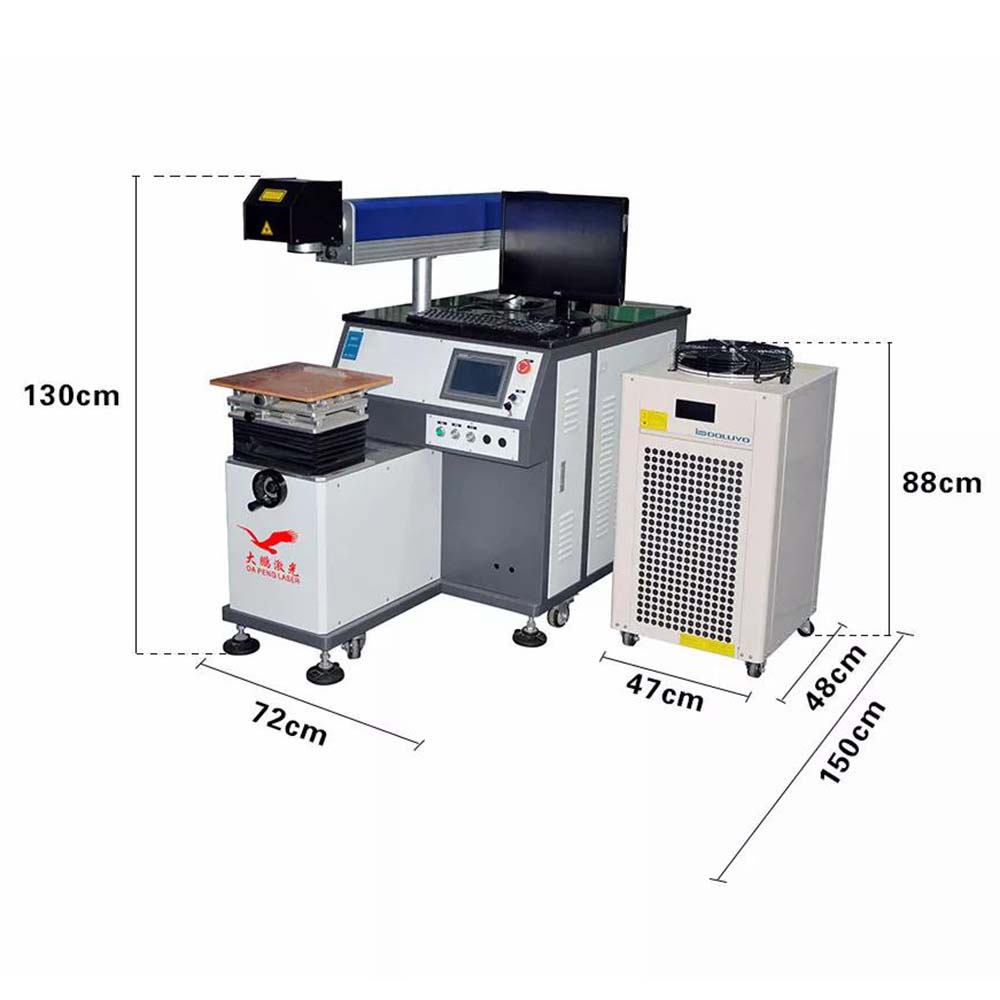

YAG Automatic Laser Spot Welding Machine

Galvanometer scanning YAG spot laser welding machine for jewelry, stainless, nickel steel, aluminum alloy, copper, gold, silver, titanium metal materials. The galvanometer laser spot welding machine utilizes a high-speed scanning head for welding, achieving speeds of up to 15,000mm/s, significantly enhancing production efficiency. The digital scanner interface exhibits strong anti-interference capability, ensuring better stability. Equipped with dedicated control software compatible with various file formats and a high-power cooling system, it meets the demands of mass production. The machine is user-friendly, allowing easy operation, and offers the flexibility to adjust current waveforms as needed.

Vibro mirror laser spot welder uses a scanning oscilloscope to achieve a dynamic welding process. It uses the movement of the scanning lens instead of the movement of the workpiece or the movement of the welding mirror set to enable the laser beam to switch quickly between the welding joints to achieve higher efficiency, the work efficiency is 4~10 times than traditional laser spot welding. YAG laser spot welder is mainly used in the welding process of jewelry metal material, with elegant and solid welding spot, small heat-affected zone, high efficiency and low cost.

Main Advantages:

1. Spot welding, butt welding, stitch welding and sealing welding can be performed on the workpiece.

2. Fast welding speed, high aspect ratio, small heat-affected zone and small deformation during welding.

3.The internal structure of the laser head is completely sealed, accurate and convenient adjustment, and good welding effect. Equipped with CCD vision system to monitor the welding effect in real time.

Features:

1. Fast speed, high efficiency, large depth, small heat affected area, high welding quality, no contamination of welding points, high efficiency and environmental protection.

2. The output power of the laser is stable, the operation process of the equipment is stable and reliable, and the processing consistency is high.

3. Corrosion resistance, high temperature resistance, high photoelectric conversion efficiency.

4. Laser energy, pulse width and frequency are adjustable, suitable for welding various metals.

5. The unique YAG crystal cooling method improves the beam quality and the life of the xenon lamp, reducing the cost of use.

Application:

Vibration mirror automatic laser welding machine is widely used in tiny parts of precision machining, rings, pendants, bracelets, dentures, and cell phone charger interface, hardware, clock, sports, golf, medical devices, especially for gold and silver jewelry fill the holes, weld line, embedded parts welding.