10W 20W 30W 50W Visual Positioning Flying Fiber Laser Marking Machine

Automatic visual positioning laser marking machine is a specialized type of laser engraving machine that is designed for high-speed flying production lines. The CCD vision laser marking system realizes efficient and accurate marking of products by integrating vision positioning technology. The core lies in templating and storing the product features as a standard reference. In the actual processing, the CCD camera captures the product image and compares it with the pre-stored template, and the computer quickly completes the position identification and calibration, thus guiding the laser head to carry out accurate marking. This process is not limited by the shape of the product, whether it is round, square or complex irregular shapes can be recognized and processed.

Standard laser marking machine can only mark one product at a time, requiring manual feeding, positioning marking and unloading. And DPLASER automatic positioning flying laser marking machine can realize continuous marking, no need manually locate the marking position, just place the product in the scanning range of the CCD camera.

The CCD camera positioning laser marking machine is especially suitable for marking on 3C industry,auto industry, medical equipments, electronic components, IT industry, hardware industry, precision instrument, crafts, ultra high-precision parts which is not easy to be positioned by hand, such as: electronic components, IC chips, circuit boards, resistors, metal jewelry, pens, etc.

Automatic Visual Positioning Laser Marker Configuration

High-speed scanning mirror

It is composed of X-Y optical scanning head, electronic drive amplifier and optical mirror. The signal provided by the computer controller drives the optical scanning head through the driving amplifier, so as to control the deflection of the laser beam on the X-Y plane.

Laser Field Mirror

In the same primary optical system, an additional field lens will reduce the area of the detector. If the same detector area is used, the field of view can be expanded and the incident flux can be increased.

Product Features

- Matching optical fibre, green light machine, CO2, UV light, EP terminal pumping etc. machine types to combine with automatic platform, meet diverse customers’ requirements.

- The positioning accuracy can reach ±0.03mm according to the hardware configuration.

- Assembly line production process, mark one or more products at once depending on product size. High efficiency, easy for beginner. The production capacity is 3~5 times that of ordinary laser marking machines.

- The marking process is automated, non-contact, non-toxic, and non-polluting.

- High-speed scanning galvanometer system, stable output power, good optical mode, and excellent beam quality.

- The product can be placed at any angle without fixtures. No need for consumables, low cost of use.

- Special product marking can play a very good role in anti-counterfeiting and won’t wear out.

- The equipment performance is stable, and it has the ability to work continuously for 24 hours.

- Compatible with document output by Auto CAD, CorelDRAW etc. multiple software, carry out bar code, two-dimensional code, graph words etc. marking, support PLT,PCX,DXF,BMP etc. document format, direct use SHX,TTF fonts.

- System can automatic coded, printing serial number, batch number, date etc. Providing standard network interface, serial port,USB port, meet the requirements of data transmission and equipment extension.

- It can be equipped with assembly line, robot arm or other automatic loading and unloading mechanism to realize automatic fully automated production.

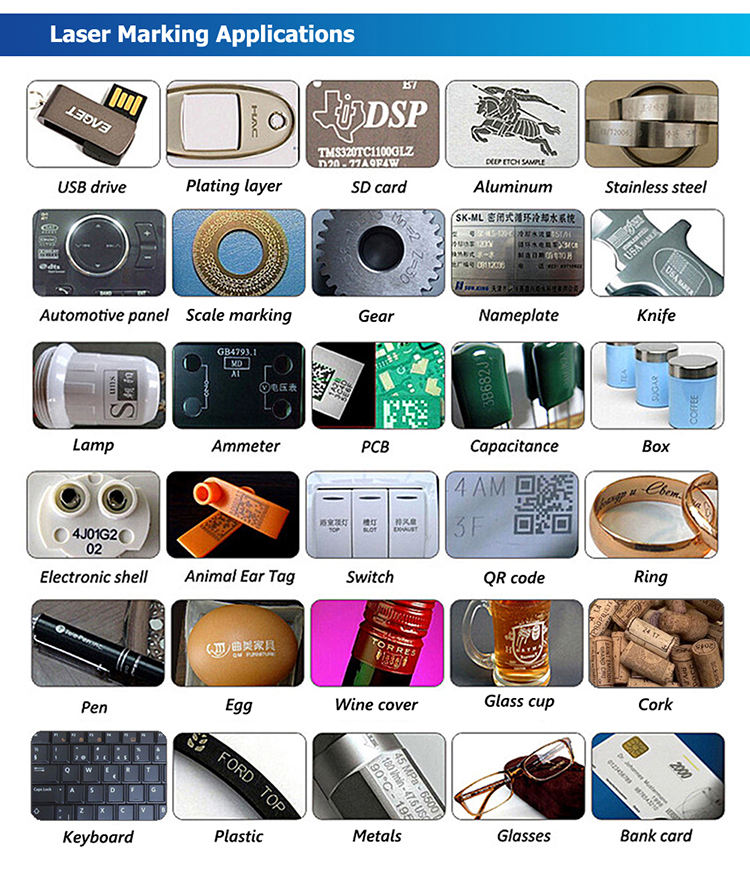

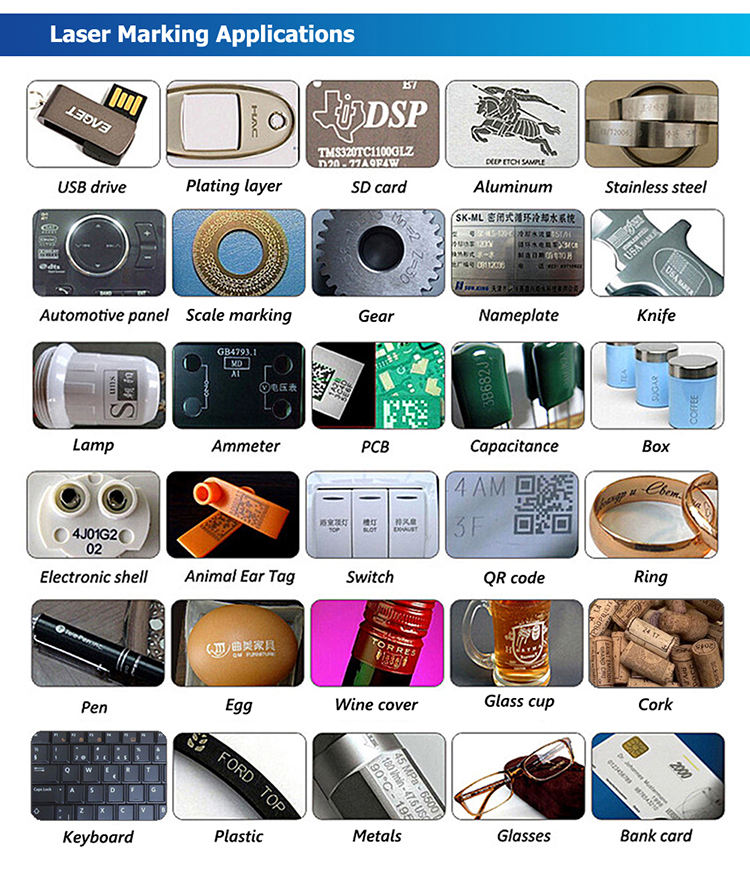

Applications

Visual positioning laser marker is especially suitable for marking on product which is not easy to be positioned by hand, such as: food packaging, circuit boards, resistors, metal buttons, pens, power plug, electronic components, capacitors, integrated circuit (IC) cards, small screws and other precision parts, as well as jewelry and other product series with complex appearance and variable dimensions.