UV Laser Marking Machine for Plastic, Silicon, Glass

UV laser marking machines adopt high-performance ultraviolet laser and digital high-speed scanning galvanometer for engraving plastics, including PP (polypropylene), PC (polycarbonate), PE (polyethylene), ABS, PA, PMMA, silicon, glass and ceramics. With small heat-affected area, good beam quality and small focus spot advantages, which can engrave ultra precision metal and non-metal materials, especially special chips and other fine marking.

UV laser engraving machine is a non-contact, precise, and efficient device used for engraving, etching, or marking objects with text, graphics, barcodes, serial numbers, and other types of information.

- The UV laser operates at a short wavelength and a smaller focal point, allowing for extremely precise marking.

- It falls under the category of cold processing, resulting in minimal heat impact on the material being treated, thereby preventing damage and yielding a high success rate.

- It finds use across a broad spectrum of materials, compensating for the limitations of infrared laser processing.

- Employing a high-speed digital galvanometer facilitates swift marking, granting both efficiency and remarkable accuracy.

- Comparing with traditional solid laser marking machine, angle of divergence is only 1/4 of diode pump laser device. It is especially suitable for precision marking.

Why Choose UV Laser Marking Systems for Plastic, Silicon, Glass, Ceramic

- Near-perfect marking quality: 355nm output wavelength reduces the thermal impact on the processed parts; vibrating mirror type high-precision marking head marking effect is fine and repeatable processing; high-precision and detailed spot to ensure perfect marking results; marking process is non-contact, marking effect is permanent.

- It is more suitable for processing materials with high reaction to heat radiation.

- Can cooperate with the production line, automatic loading and unloading, automatic feeding and unloading.

- Suitable for marking on most metal and non-metal materials.

Product Advantages

- Short UV laser wavelength and smaller focused spot for ultra-fine marking.

- Cold processing, small heat-affected zone, avoiding damage to the processed material, high yield.

- Wide range of applicable materials to make up for the lack of infrared laser processing capability.

- High-speed digital galvanometer for fast marking speed, high efficiency and high precision;

- No need for consumables, low cost of use and maintenance; stable performance of the whole machine, can run for a long time.

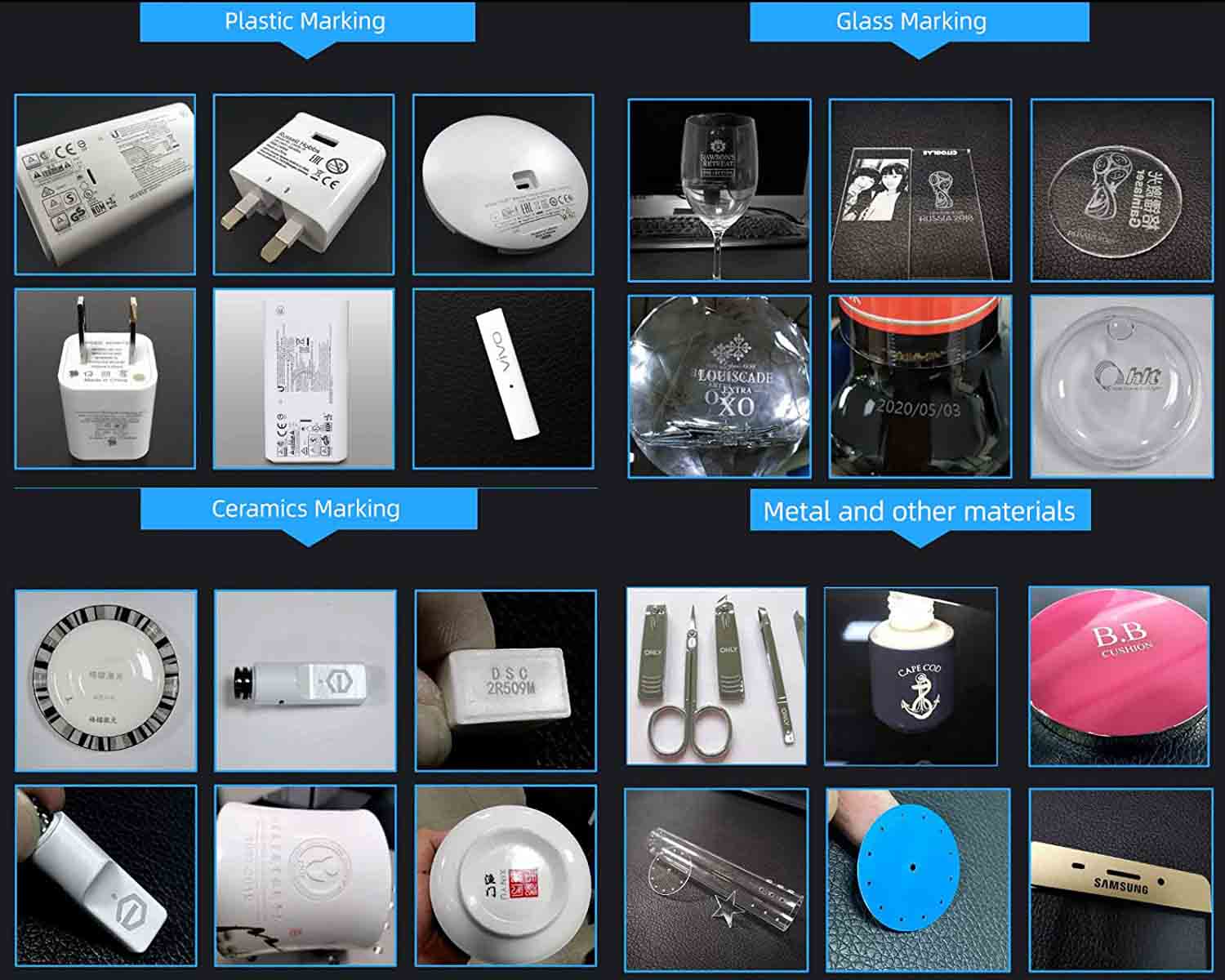

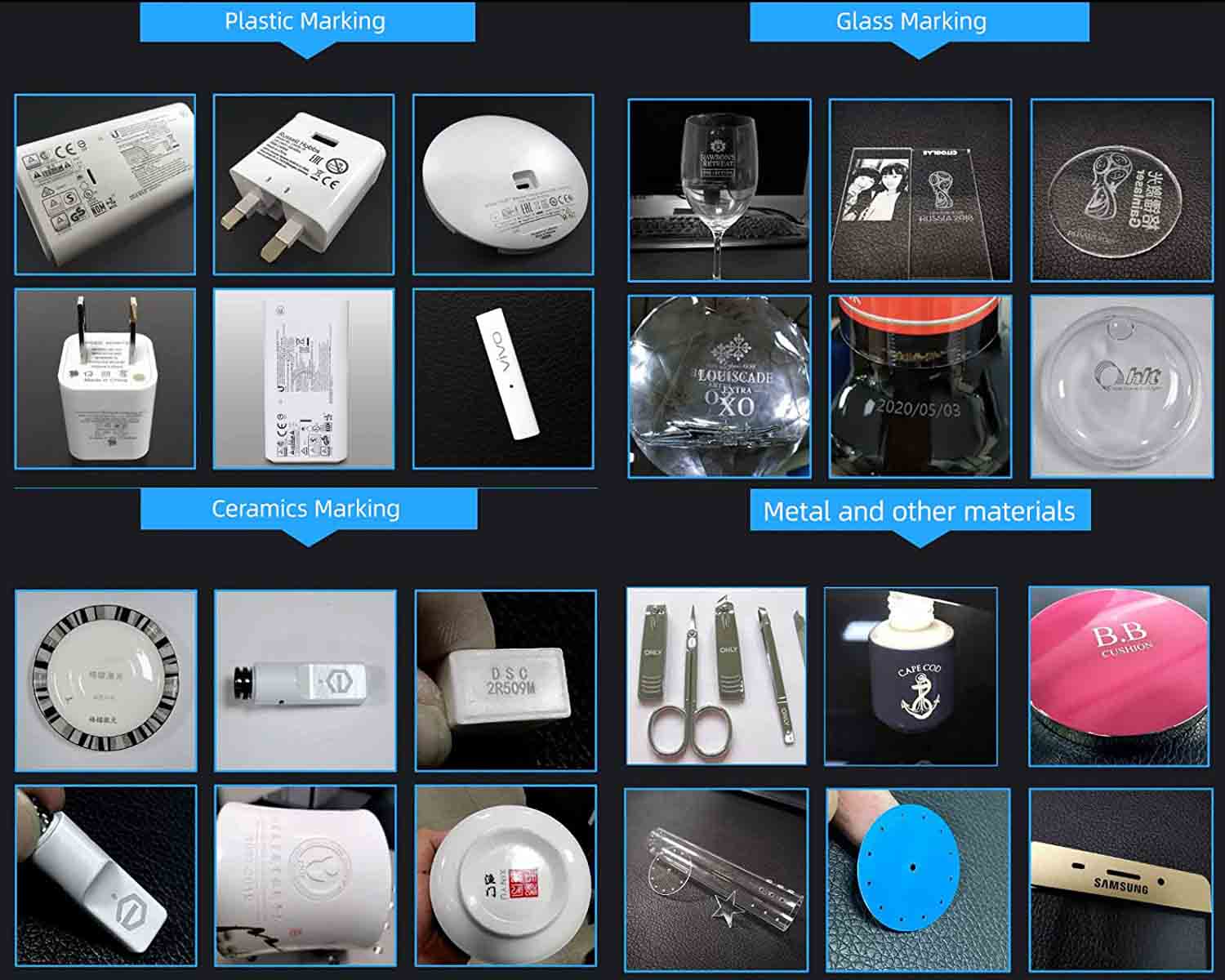

Ultra Fine UV Laser Engraver Applications

- Suitable for marking the surface of glass, polymer materials and other objects, microporous processing.

- Widely used for marking the surface of packaging bottles (boxes) of polymer materials, such as food, drugs, cosmetics, wires, etc., and micro-hole punching (aperture d≤10μm).

- Flexible PCB board, LCD, TFT marking, scribing and cutting.

- Metal or non-metal plating removal

- Silicon wafer microvia, blind hole processing.

What Materials Can Be Marked

PP (polypropylene), PC (polycarbonate), PE (polyethylene), ABS, PA, PMMA, Silicon, Wood, Leather, Acrylic, Fabric, Surface of Plated Film, Glass, and Ceramics.