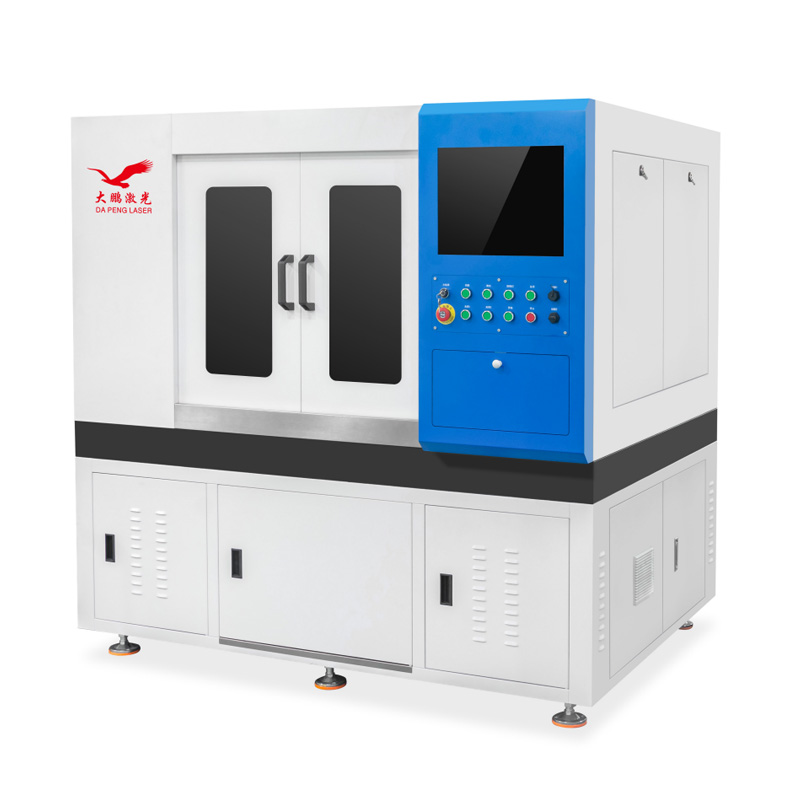

Stator Mover Precision Laser Cutting Machine

The precision fiber laser cutting machine for stator and mover is a high-precision cutting equipment specially used for processing stator and mover. In the motor manufacturing and power industry, the stator and mover are the core components of the motor, and their accuracy is critical to the performance and efficiency of the motor. Laser cutting technology can achieve fine cutting and processing of stators and movers by using high-energy laser beams.

Precision laser cutting machine has many advantages in the processing of stators and actuators. Firstly, it can realize high-precision cutting and ensure the accuracy of the size and shape of the stator and the mover.

Secondly, the precision laser cutting machine has a small heat-affected area. This means that during the cutting process, the heat is concentrated only in a very small area, minimizing the thermal deformation or thermal stress of the material, thus ensuring high-precision processing of stators and actuators.

In addition, the precision laser cutting machine has high processing speed and efficiency. It can quickly complete the cutting task of stators and actuators, increase productivity and reduce manufacturing cycle time. This is essential for mass production and fast delivery.

For different types of stators and actuators, the precision laser cutting machine can be flexibly adapted. Whether it is a round stator or a shaped kinematic, the laser cutting machine can cut with high precision according to the design requirements and meet the needs of various motor structures.

- Adopts gantry structure with fully enclosed protectionfor linear motors and guide rails to reduce dust contamination.

- Utilizes dual- side drive linear motors for high precision, large acceleration, and fast speed.

- Laser processing is an non-contact flexible method that is not affected by the shape of the workpiece, enabling the cutting of any expected shape.

- Equipped with a dedicated laser control system that is powerful and easy to learn, suitable for technicians with Low entry requirements.

- Capable of cutting various metal foils, primarily used for silver and copper foils.

- Mainly applied in precision electronics industry.