Professional Fiber Laser Pipe Cutting Machine

Fiber laser cutting system for tube with CNC exchange platform aim to increase the productivity, flexibility and cutting quality of tubes and profiles finishing with more precise fiber laser cutting. The fiber laser tube cutter is capable of high- speed cutting of rectangular tubes, square tubes, elliptical tubes, round tubes and profiles such as angle steel and channel steel. It offers features such as high speed, high precision, and cost – ffectiveness. Utilizes dedicated tube cutting software with core technology for efficient cutting, which is a fundamental guarantee for material savings and enhanced cutting efciency.

- Aviation grade aluminum beam

Aviation-grade aluminum features corrosion resistance, light weight and high rigidity, ensuring high-speed laser cutting - High-quality thick-walled carbon steel plate welding bed

The high-strength bed is more stable and durable. The bed has been annealed for stress relief at 600°C, with strong structural rigidity. The overall mechanical structure of the machine has little deformation and vibration, ensuring cutting accuracy. - Independent control cabinet

All electrical components and the laser source are built into a separate control cabinet to prevent dust accumulation. - Integrated large air volume dust removal system

The dust extraction system can remove all the fume and dust generated during the cutting process with high air volume.

Advantages of Professional Fiber Laser Pipe Cutter:

- Laser cutting machine can quickly cut rectangular tubes, square tubes, oval tubes, round tubes and shaped tubes, and

angle steel, channel steel and other profiles, With high speed, high precision, cost-effective features. - Horizontal structure, stable operation, high precision;

- Intelligent cutting software, intelligent cutting;

- Imported servo motor to improve the cutting speed of the whole machine;

- Configure automatic feeding and remnant material systems for mass production.

- The machine is highly integrated, with good system performance and long life, automatic lubrication;

- Highly automated, strong anti-interference ability, fast dynamic response;

- Centralized operation, flexible processing, automatic feeding, pneumatic chuck clamping convenient and fast;

- Simple maintenance and maintenance, basic maintenance-free;

- Use dedicated laser cutting software, with the core technology of efficient cutting.

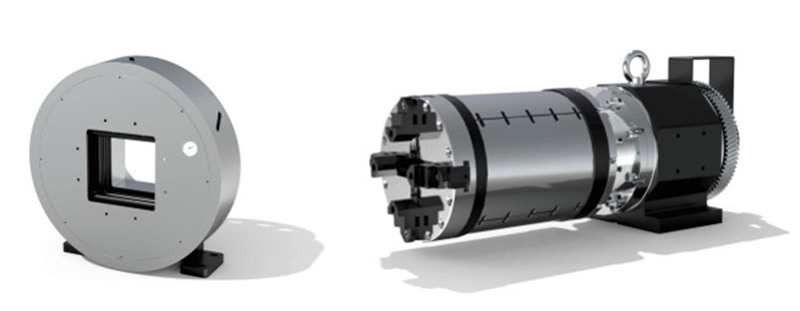

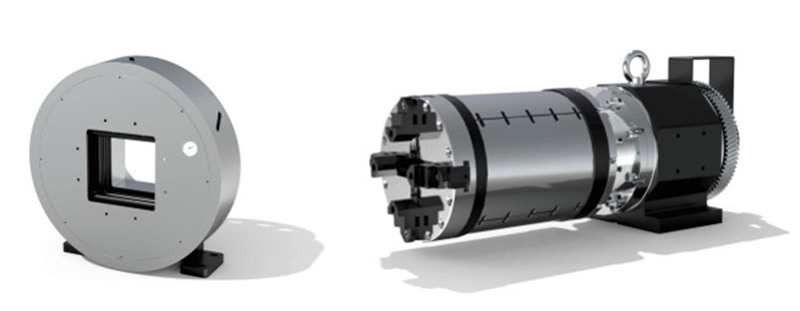

Chuck:

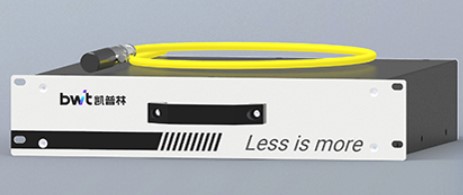

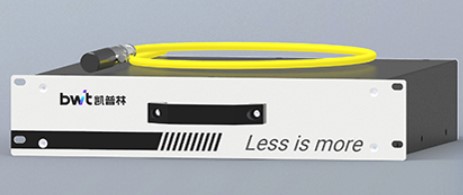

| Lasers: Raycus/MAX/BWT

|

Laser Cutting Head: Osprey

|   |

| Servo Drive Utilizing a bus control method to ensure precise positioning and optimal dynamic response, this guarantees smooth and reliable operation of the automatic positioning mechanism with minimal maintenance. High-power motors drive the X, Y, and Z axes. |

| Transmission Components Fast speed, high precision, and strong reliability ensure long and stable operation. Higher speeds with lower noise levels guarantee high accuracy and extended lifespan. |   |

| Servo Feeding Device Servo-controlled material feeding and clamping for cutting, reducing material pulling, and improving efficiency. A single cutting stroke can reach up to 1.2 meters. |

| Laser Cutting System FSCUT3000DE is a control system developed for the processing of pipes, supporting high-precision and high-efficiency cutting of square tubes, round tubes, elongated tubes, oval tubes, as well as angle steel and channel steel. |   |

| Laser Cutting Power Head Independently developed for high precision, the power head undergoes multiple tests to quickly clamp and enhance work efficiency. The clamping force is stable, reliable, and adjustable, allowing for fast cutting speeds and excellent accuracy. It is worry-free for cutting profiles, making it widely applicable to both batch and single-item processing enterprises. |

Laser Chiller

|   |

Samples:

The applications of laser processed pipes and profiles are diverse, from the automotive industry, mechanical engineering, architecture construction, furniture design to petrochemical industry, etc. Laser cutting of tubes and profiles provides a wider manufacturing range for metal parts and offers flexible and unique design possibilities.