Mini Handheld Laser Welding Machine

Portable laser welding machines are lightweight and easy to carry. Unlike traditional welders or robotic welding systems, these compact machines are user-friendly and easy to set up. This makes them suitable for both professionals and beginners, and ideal for precise, demanding tasks in both outdoor and industrial environments.

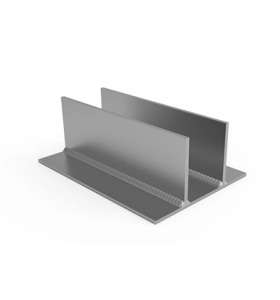

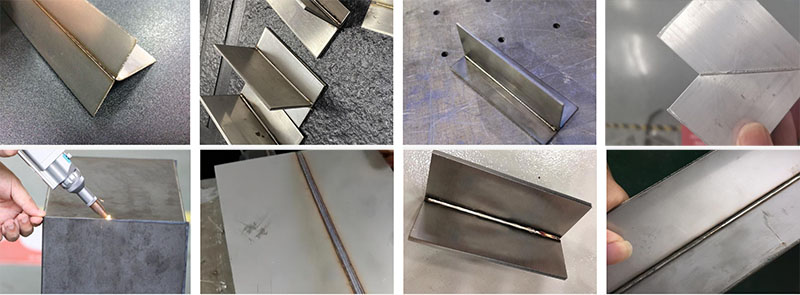

The mini handheld laser welder for edge, butt, tee, corner, and lap joints is user-friendly, easy to set up, and delivers consistent, high-quality welds across various materials and thicknesses. Ideal for both professionals and beginners. With auxiliary gas protection, a clean, high-quality weld is formed, securely joining two components.

Designed for portability, mini laser welding machines are lightweight and compact, allowing easy transport to different job sites or workshops. The handheld operation enables welding at any angle or location. Its simplicity ensures that even inexperienced welders can operate it efficiently. The compact design also facilitates easy movement in tight spaces, requiring minimal production area.

This mini laser welding machine series offers high electro-optical conversion efficiency, robust output power, superior beam quality, compact structure, maintenance-free operation, and cost-effectiveness.

Features of Portable Handheld Laser Welding Machine

- Fast welding speeds with deep weld penetration and minimal thermal deformation, ensuring superior weld quality and reduced post-processing.

- The mini handheld laser welding machine has a compact and user-friendly design, making it easy to operate. Built-in factory presets for all materials and thicknesses.

- The new handheld laser welder features an LED touchscreen and smart operating system—most beginners can master the basics in just 30 minutes.

- Welding speed is 3~5 times faster than traditional welding(Argon arc welding, arc welding, gas welding, soldering and brazing etc.)

- High-speed welding across a wide range of metals such as gold, silver, copper, iron, aluminum, stainless steel, and carbon steel, as well as challenging materials like titanium and quartz.

- Capable of high-speed welding across a wide range of metal types and thicknesses, including thick, thin, reflective, and dissimilar metals—all without requiring filler wire.

- The focused laser beam produces an ultra-fine spot ideal for micro welding applications, enabling high-precision positioning.

- It supports a variety of welding methods—including groove welds, fillet welds, tee welds, spot welds, and surfacing welds—and allows for flexible operation at virtually any angle or position.

- The laser machine offers a long service life of up to 100,000 hours, ensuring reliable performance over time.

Advanced Laser Source

User-friendly and efficient, achieving more precise results and welding speeds up to 4X faster than TIG and MIG!

Digital Control System

Adjust welding parameters with ease, and switch between multiple welding modes at will! From precise spot welding to continuous welding, ensure you get the best results and quality every time you weld. The operation screen has a user-friendly touchscreen. It enables quick startup for users at any skill level.

New Design Laser Weld Gun/Humanized Design

Our hadheld laser welding gun is lightweight, ergonomic design weighs just 0.8kg. It’s built for comfort during long hours of work. The small and lightweight design makes them easy to handle and suitable for welding in tight spaces or for intricate welding tasks.

Wire Feeder

If two weld metal gap more than 0.2mm that need filler wire.

Laser Welding Copper Nozzles

Laser welding heads come with different nozzles to improve flexibility and material compatibility. These nozzles make the equipment more versatile and suitable for various welding tasks. Specialized nozzles also enhance laser beam control and precision, boosting welding performance.

Handheld Laser Welding Mode

Various Metal Materials

|

|

|

|

| laser welding aluminum | laser welding carbon steel | laser welding stainless steel |

laser welding copper |

Application industries

Metal manufacturing and processing industries, such as metal welding, surface welding of electrical switch cabinets, elevator manufacturing, household appliance manufacturing, stainless steel stove, frame, doors and windows, fence, electric box, pipeline, and kitchenware manufacturing. Welding of various metal materials such as carbon steel, aluminum alloy plate, galvanized plate, electrolytic plate, silicon steel, titanium alloy, galvanized aluminum plate, and reflective materials copper.

Why Choose DPLASER Laser Machine?

- Core Technology: We are both a manufacturer and seller of laser equipment, and can provide customized laser devices.

- Independent R&D: We can provide customized laser machines for any application of our customers, and develop new machines based on market research.

- Customer Support: We provide free technical support for equipment installation and use to help customers succeed.

- Strict Testing: All our suppliers are from world’s top manufacturers. Before delivery, each machine must undergo strict testing and inspections to ensure the quality and safety of the laser equipment.

- On-time Delivery: Each machine has an accurate assembly process and strict time control to ensure that customers receive goods promptly.

- After-Sales Service and Guarantee: We provide lifelong service for laser machines and accessories, and we are responsible for solving any problems that may arise during this period.

Reviews

There are no reviews yet.