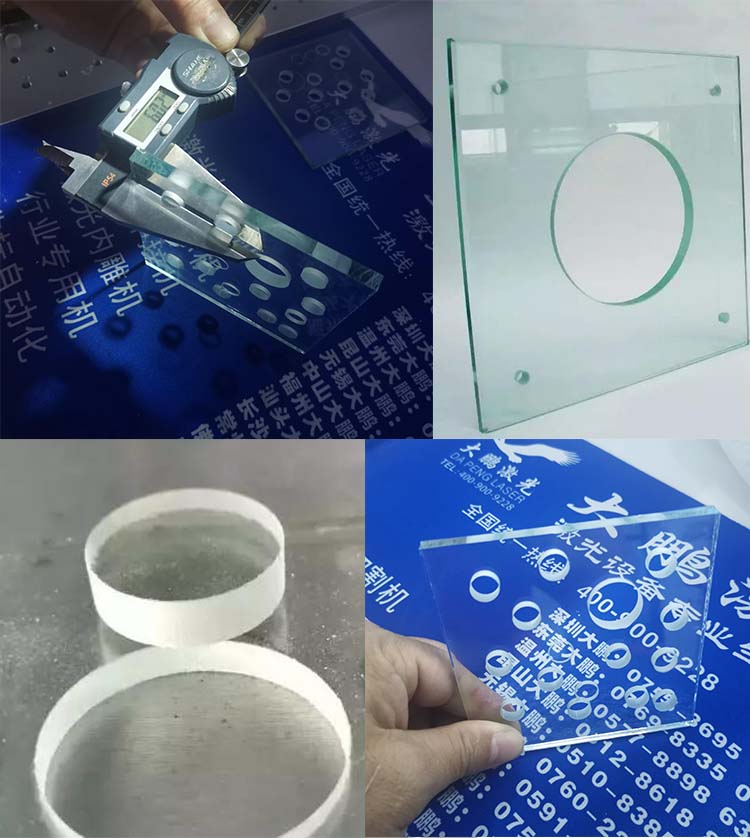

Laser Glass Drilling Machine

The laser drilling machine for glass materials offers laser marking with high precision and fine features, and is particularly suited to the handling of hard and brittle glass substrates. The laser presents a number of significant advantages over traditional methods of glass processing, laser machine drilling and sanding glass. Its ease of operation and non-contact processing ensures that the glass is not damaged by external forces, while achieving excellent glass perfection and fineness.

Features of Laser Drilling Machine for Glass

Laser System:

DP-JP-100-M8 series laser systems utilize a Master Oscillator Power Amplifier (MOPA) structure, supporting independent adjustment of pulse width and pulse frequency. While maintaining the performance of the existing series, the M8 series optimizes pulse peak power and beam quality. It excels in applications with high demands for peak power and brightness, particularly in tasks like glass drilling, where peak power exceeds 50 kW.

Scanning Galvanometer:

The rear-focused three-dimensional scanning galvanometer finds wide applications in high-end processes such as laser precision marking, laser engraving, laser deep engraving, laser cutting, and laser welding on multi-level, inclined, cylindrical, spherical, and complex 3D surfaces. Laser processing is more than 80% faster than conventional processing. By using a 3-axis galvanometer laser head, it is also possible to change the working focus of the laser inside the material, thus enabling 3D effects to be produced inside glass objects.

Lens (λ=1064nm):

The F-theta scanning lens, also known as a field lens, flat-field focusing lens, or linear lens, disperses the laser beam over the scanning area or workpiece, forming uniformly sized and focused spots across the entire marking plane.

Laser Chiller:

Water cooling system

Dual digital display

Full power cooling, micro-cooling, heating control

High-precision temperature control with fluctuations controlled within 0.5°C

Sensor fault self-diagnosis and water flow alarm functions

Highly integrated chip on the mainboard with strong anti-interference capability

Equipped with antifreeze function for better protection of machine water circuit components in low-temperature environments

Comes with universal wheels for easy mobility

Compact size, user-friendly operation, energy-efficient, stable performance, and quality assurance.

Software Features

- Advanced digital three-axis dynamic focusing technology ensures fast marking speed, high real-time zoom control, and uniform focusing spot. It achieves precise laser marking on curved workpieces without defocusing during processing.

- User-friendly operation with excellent equipment stability; specialized control software is compatible with various software outputs such as AutoCAD, CorelDRAW, Photoshop, and more.

- Capable of receiving files in various formats, including BMP, JPG, DXF, PLT, AI, etc.

Applications

This laser glass drilling machine can be applied to a wide range of processes such as drilling, cutting and marking. The applications of lasers on glass are wide-ranging and cover everything from purely decorative applications to cutting, drilling and engraving in consumer electronics, LCDs, medical devices, telecommunications and more. Some typical objects include perfume bottles, jars, glasses, jugs, cutlery, frames, mirrors, display cases, monitors, gadgets, and various decorative items.

Reviews

There are no reviews yet.