Automatic YAG Laser Welding Machine for Metal Mould Die Repair, Stainless Steel Aluminum Mold

The mold repair laser welding machine, equipped with a manually adjustable laser head and an electrically adjustable workbench, is designed for the repair of various industrial molds. Without the need to relocate the mold, the movement of the laser head is controlled by a hanging rod manipulation lever, allowing for flexible adjustments to the welding angle and position. This mould laser spot welding machine is suitable for repairing large molds, medium-sized molds, as well as manually spot welding. It is applicable to a variety of mold steels, carbon steels, common alloy steels, stainless steels, plastic molds, casting molds, forging molds, stamping molds, die-casting molds, and more.

Advantages of High Precision Mold Laser Welding Machine:

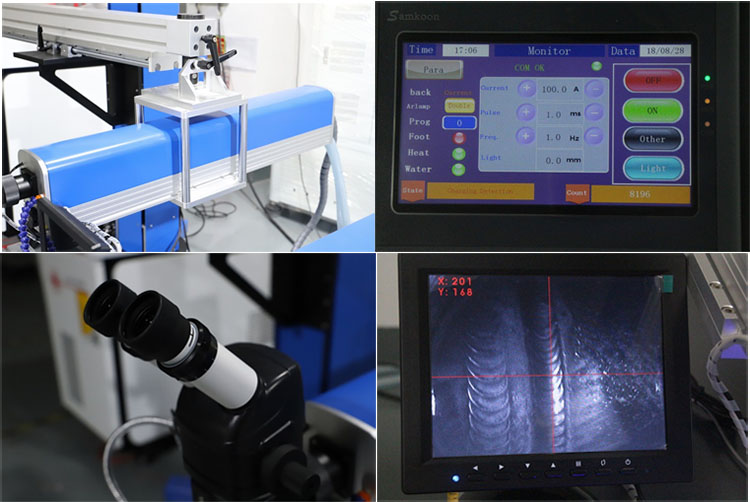

- This machine adopts the integrated design of laser head, laser power supply, internal circulation cooling system, control system, computer numerical control system and workbench.

- It has compact, beautiful appearance, convenient operation, stable performance and small space occupation.

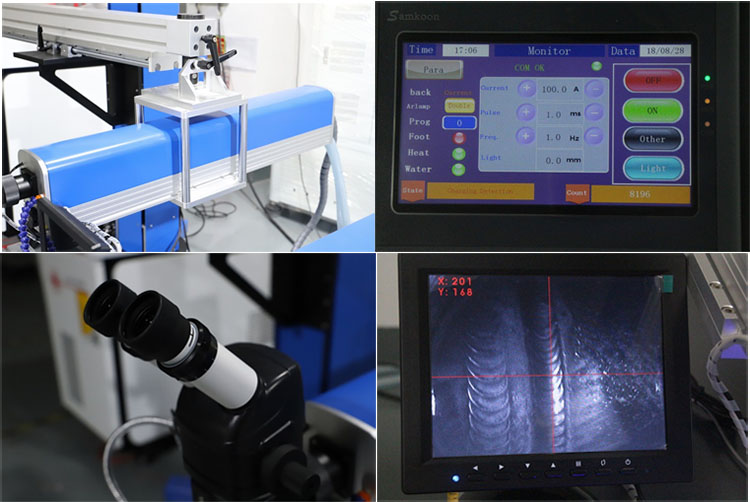

- It uses a power switch, and the output power, frequency, pulse width and other parameters of the laser can be selected through the touch screen.

- It also has an automatic protection function to prevent misoperation and temperature excursion.

- Through the remote control or touch screen, you can choose the output power, frequency, pulse width and other parameters of the laser, set the speed and control direction (forward, backward, left or right) to move the worktable, so as to produce smooth and neat welding lines or welding spots, and optimize effect.

- Drive mode of CNC workbench: imported PLC control, stable operation and high precision of the workbench.

- Simple and easy to learn control system, easy to set the parameters of the mold laser welder control system.

- 20x magnification high quality microscope allows you to clearly observe the welding position and welding result.

- Laser welding focusing lens F=150, welding head angle can be adjusted according to the exact welding angle.

- CCD camera helps you to easily view the welding result and adjust the precise welding position.

Application Industry:

1.The mold repair laser welding machine is used to repair set foot part welder parts claw, fill sand holes and small teeth precision components such as batteries with nickel, integrated circuit leads, watches and clocks, gold and silver jewelry, spot welding, repairing, and inlay and welding of claw.

2. It is also applied for the fast welding of various metal letters, stainless steel letters, LED luminous characters, AD Logos, customized metal signage and exterior billboards. It’s widely used for Logo making, fine word production, metal word production, Copper factory, advertising production and so on.

What Materials Laser Welding Machine for?

Stainless steel, steel plate, iron plate and other metal and alloy. Suitable for welder of kettle, vacuum cup, stainless steel bowl, sensor, tungsten wire, high power diode (triode), aluminum alloy. The shape of welding point: circle, arc and square, etc.

Notice:

When using the mold laser welding machine to repair the mold, use a microscope to observe the mold and repair welding conditions, and observe with both eyes at the same time, so that the specific conditions of the mold can be observed during observation.

The welding wire must be selected correctly during operation, because the mold can only be repaired if the welding wire is selected correctly (the diameter can be melted from 0.2-0.8). If it is not used correctly, it will affect the repair effect of the mold and even fail to repair the mold.

The mold laser welding machine must use argon protection, and the program should be set to first argon and then laser to prevent oxidation in the first pulse laser during continuous processing.