1000W 1500W 2000W 3000W Handheld Fiber Laser Welding Machine

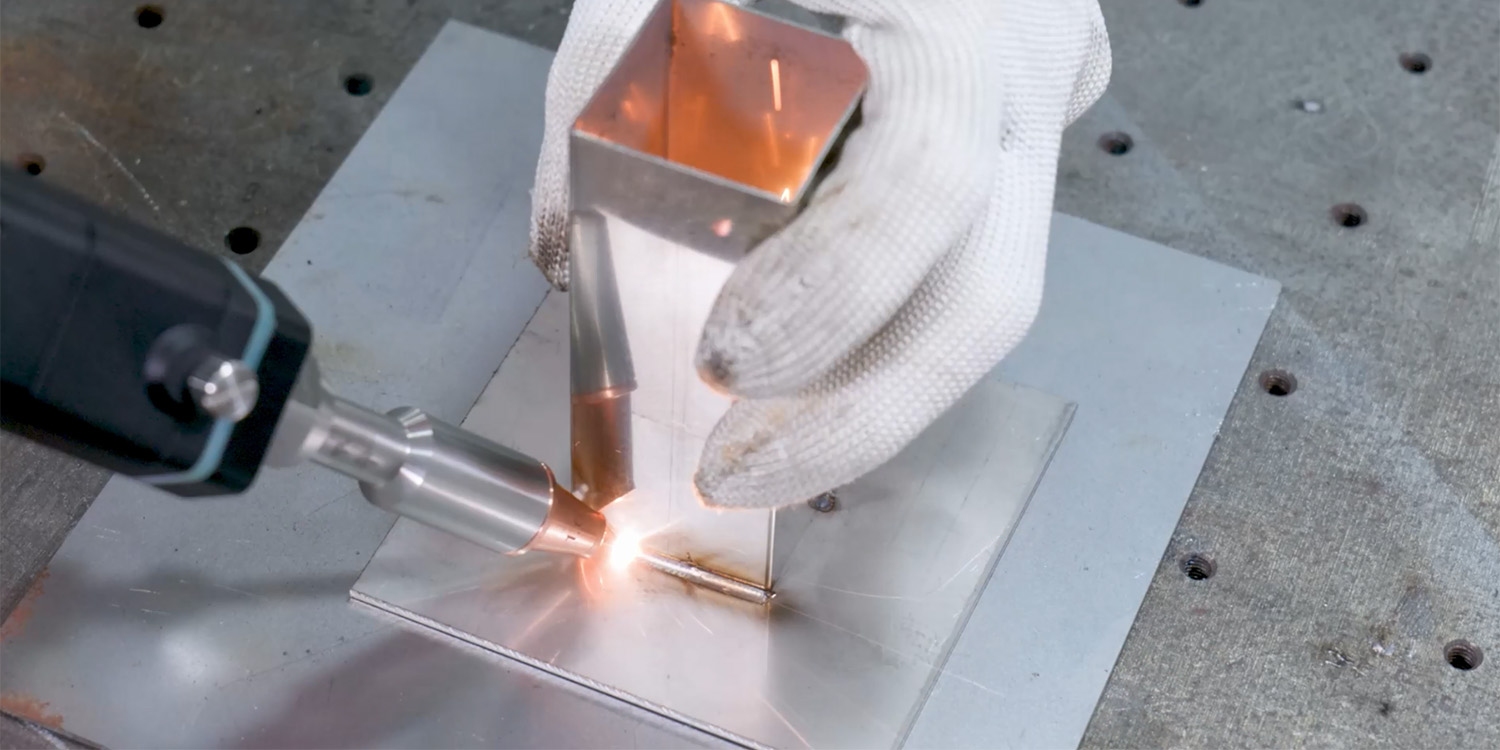

The handheld laser welder is easy to learn and operate, capable of producing high-quality welding results on various materials and thicknesses. The weld seams are smooth and aesthetically pleasing, requiring no secondary grinding or post-processing. The high-speed welding efficiency contributes to increased productivity. This handheld metal laser welding machine has 5-in-1 metal welding functions, including spot welding, seam welding, pulse welding, continuous welding and repair welding, which can meet a variety of welding needs.

Features of Handheld Laser Welder:

- New type of metal welding method, mainly for thin-walled materials, precision parts welding

- It can realize spot welding, butt welding, stack welding, sealing welding and so on.

- High depth-to-width ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, flat and beautiful weld, no need to deal with after welding or just simple treatment

- High quality of weld seam, can be precisely controlled, high positioning accuracy, easy to realize automation.

Laser Source(RAYCUS/MAX/BWT optional):

High power and high quality laser output

High electro-optical conversion efficiency, spot energy star flat-top distribution, high energy density

Anti-high reflection

Adopting unique and innovative hardware level anti-high reflection protection technology, it can process all kinds of high reflectivity materials.

Compact structure, smaller size

Built-in high-power single-module integration, the whole machine is smaller in size.

Modularized design, easy maintenance

Separate photoelectric module design, stable operation, less failure, and more convenient for later maintenance.

Excellent performance, low processing costs

Processing efficiency can be increased by up to 532%, annual cost savings of up to 1.1 million

Wide range of applications

Can be used for cutting, welding, drilling, cladding, additive manufacturing, surface heat treatment, etc. of metal and non-metal materials.

surface heat treatment, etc.

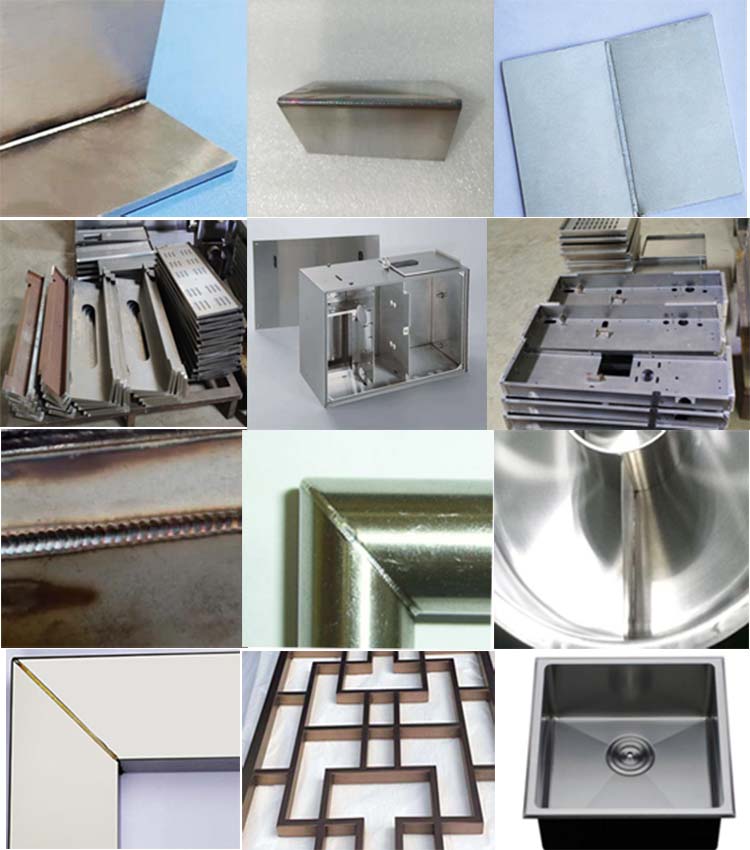

Various Metal Materials

|

|

|

|

| laser welding aluminum | laser welding carbon steel | laser welding stainless steel |

laser welding copper |

Laser Welding Head:

The portable laser welding machine features a handheld welding gun design, replacing the fixed optical path system to enable more flexible, long-distance, and outdoor welding. It easily connects to shielding gas, ensuring stable and reliable weld quality.

Interface type: QBH

Laser Incidence: Coaxial

Laser power: 1000W~3000W optional

Laser wavelength range: 1070±20

Collimation focal length: 80mm /D20

Focusing distance: 150mm,400m/D20

Protective gas: nitrogen / argon and other inactive gas

Weight: 0.75kg

Adjustable width: 0-6mm

Automatic Wire Feeder Kits:

- For a more perfect welds

- For metallic and non-metallic materials such as carbon steel, stainless steel, aluminum, galvanized sheet, non-ferrous metals and alloys

Welding Software:

The open CNC system allows the user to integrate third-party specialized software or technology into the system. A range of open tools is also available, allowing the user to customize their own personalized interface and special features as required.

- Realization based on data acquisition

- Welding Processing Status Current Processing Tasks

- Real-time monitoring of welding

Handheld Laser Welder Application:

DPLaser handheld fiber laser welder is versatile and can be applied in the welding of precision metal components used in various industries, including kitchenware manufacturing, electronic products, advertising, mold fabrication, stainless steel doors and windows, handicrafts, furniture, automotive accessories, gifts, accessories, sheet metal, PCB, packaging, jewelry, semiconductors, and more.

The wire feeder is designed to automatically feed the wire during the welding process, suitable for both industrial and home use. Handheld torch is more flexible and convenient to meet various angles and positions of welding. Welding seam is beautiful and solid, simple, fast and flexible operation, low processing cost. Compared with arc welding and TIG welding, there is 3~4 times improvement in efficiency.

Reviews

There are no reviews yet.