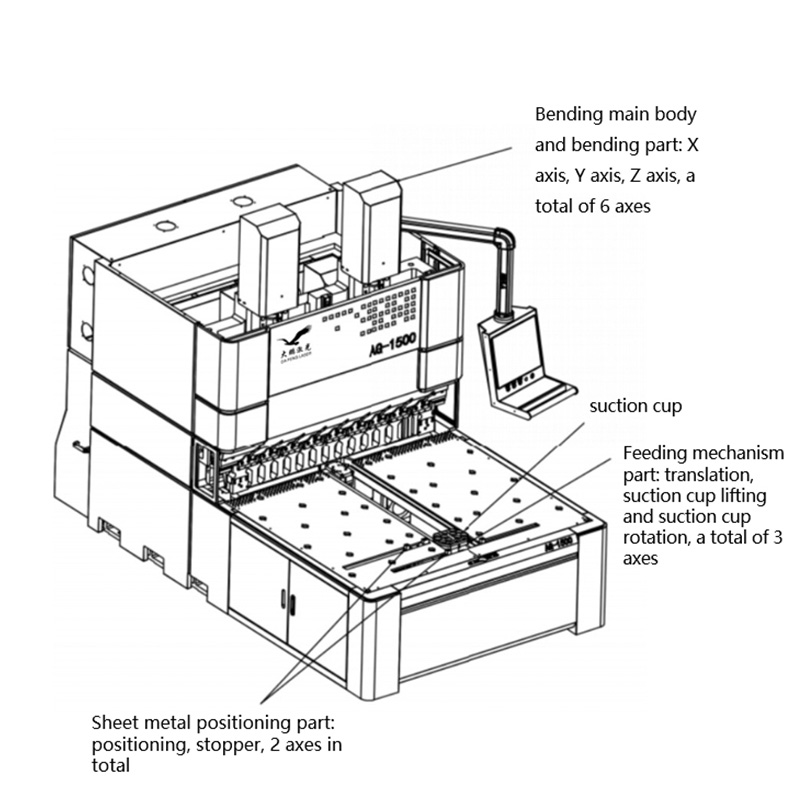

Automatic Sheet Metal Folding Machine CNC Panel Flexible Bender

CNC metal press brake bending machine is a specialized machine used for bending and forming sheet metal and other materials. It allows for precise and automated bending of metal panels, making it a valuable tool in various industries such as manufacturing, construction, and sheet metal fabrication.

The AG/AGP series is a flexible CNC bending machine designed and manufactured to high-precision machine tool standards. It employs high-grade castings, and both castings and welded components undergo rigorous stress relief processes. High-precision machine tool processing is performed to ensure long-term operational accuracy, stability, and high rigidity of the entire machine.

– High-quality castings for equipment frame, designed for stability under high impact forces.

– Precision carbon dioxide protection welding to ensure firm and attractive welds.

– Extensive heat treatment and vibration aging to relieve internal stress in the workpiece.

– Utilization of a high-precision multi-axis machining center for consistent accuracy before and after clamping.

Features:

1. Precision: CNC control ensures high accuracy and repeatability in bending operations, resulting in precise and consistent parts.

2. Versatility: These machines can be used to bend a wide range of materials, including steel, aluminum, stainless steel, and more. They can also handle various thicknesses and shapes of metal sheets.

3. Speed and Efficiency: CNC Metal Panel Benders are capable of high-speed bending, which increases production efficiency and reduces lead times.

4. Complex Shapes: They can create complex and intricate shapes that might be difficult or impossible to achieve with manual bending methods.

5. Reduced Labor Costs: Automation reduces the need for skilled operators, saving on labor costs and minimizing the risk of human error.

6. Quick Setup: CNC Metal Panel Benders can be programmed to change setups rapidly, making them suitable for small-batch and custom production runs.

7. Cost-Effective: While the initial investment in a CNC Metal Panel Bender may be substantial, the long-term cost-effectiveness can be significant due to increased productivity and reduced scrap.

8.Integration with CAD/CAM Systems: CNC Metal Panel Benders often work in conjunction with computer-aided design (CAD) and computer-aided manufacturing (CAM) software, allowing for seamless part design and production.

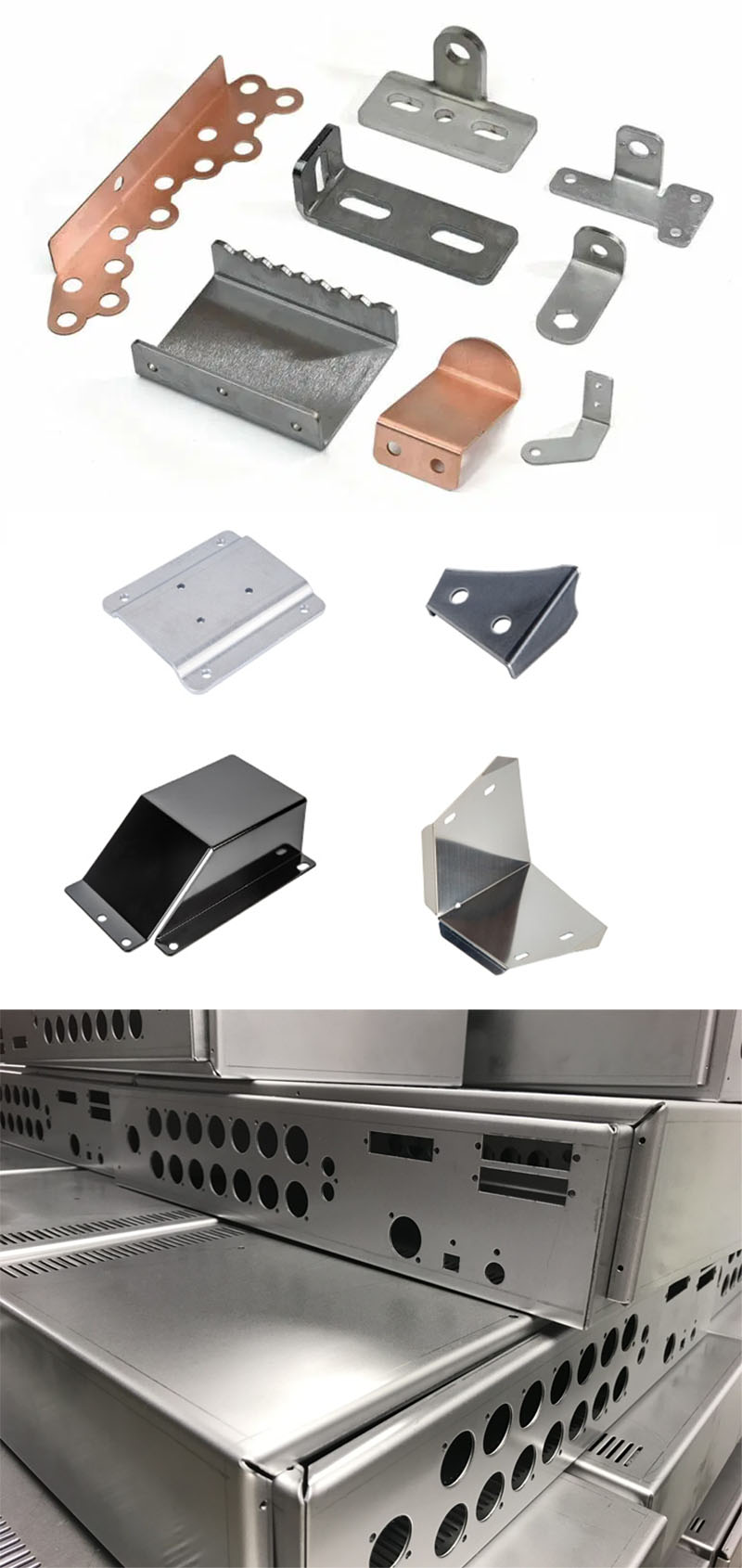

Application:

CNC metal bender are commonly used in the production of metal cabinets, enclosures, signage, kitchenware, furniture, doors and windows, automotive parts, and HVAC components, among others. CNC Metal Panel Benders have revolutionized the sheet metal fabrication industry by streamlining the bending process and improving the quality and efficiency of metal forming operations.

Reviews

There are no reviews yet.