YAG Laser Spot Welding Machine for Jewelry Repair & Design

The automatic YAG spot laser welder is capable of performing automatic or semi-automatic spot welding, butt welding, stack welding, and seal welding. It is equipped with a four-dimensional ball screw table and an imported servo control system, allowing it to target complex plane straight line, arc, and any track welding. The machine is user-friendly, with the ability to adjust the current waveform arbitrarily. It offers high welding accuracy, fast speed, and produces effective results.

Jewelry laser welding machine is mainly used in perforating and spot welding of white gold, platinum, carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized sheet, silicon steel sheet, titanium alloy etc.

Features:

- Large penetration ratio, small deformation, no pollution in solder joints, no air holes in solder joints, smooth and beautiful appearance, no need or only simple post-processing.

- The output power of the laser is stable, the operation process of the equipment is stable and reliable, and the processing consistency is high.

- Corrosion resistance, high temperature resistance, high photoelectric conversion efficiency.

- Laser energy, pulse width and frequency are adjustable, suitable for welding of various metals.

- Fast speed, high efficiency, large depth, small heat-affected zone, high welding quality, no pollution of solder joints, high efficiency and environmental protection.

| Microscope and camera system Binocular microscope, microscope and CCD synchronous display, very convenient for real-time observation of the welding effect of the sample. |

| Interface Color touch screen, friendly man-machine interface, just simply set the parameters, easy to operate. |   |

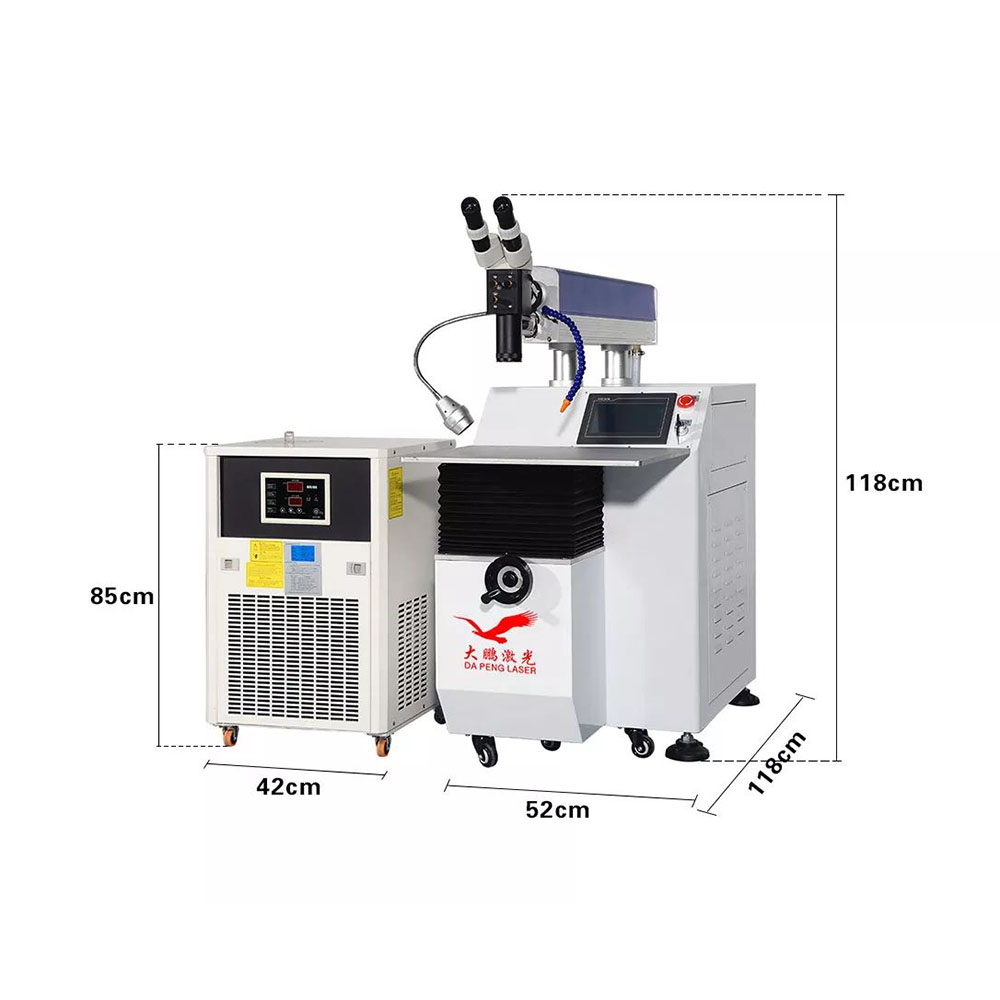

| Water cooling system Aluminum alloy material, more powerful heat dissipation, water cooling to reduce the use and maintenance costs. |

| Air blowing tube The angle of the blowing tube can be adjusted at will. Compact design saves studio space. Prevent oxidation and blackening of workpiece by blowing nitrogen or argon gas. |   |

| Foot switch External foot pedal controls laser emission, click once, light out once, easy to use and change control. |

| High productivity Fast welding speed, noiseless operation, much higher welding efficiency and significantly reduced welding time. |   |

Application:

YAG jewellery laser spot welding machines can weld materials such as gold, silver, platinum, titanium and its alloys, electric nickel strips, etc. It can be used for precision welding lithium batteries, battery packs, electrodes, diodes and relays. In the electrical industry, laser spot welding is used to join air conditioner motor rotors, leakage protectors and silicon steel sheets. The kitchen and bath industry also employs this technology for the manufacture of kettles, faucets, plumbing fittings, valves, sinks and shower heads. In addition, the eyewear industry utilizes laser spot welding technology to join the outer frames of eyeglasses made of stainless steel and titanium alloys for a precise and efficient welding process.

DPLASER: The Top China Manufacturer in Laser Welder

1) Top professional laser equipment manufacturerin China. More than 10,000 machines have been sold overseas in recent years.

2) A wide range of laser marking engraving machines, cutting machines and welding machines(Fiber, CO2, UV, Mopa) in stock, lead time 5~7 days.

3) Door to door service and lifelong technical service.

We provide 1 year warranty, manual or operation video in English, technology support online or door to door anytime.