Industrial CNC Laser Cutting System for Metal Tube

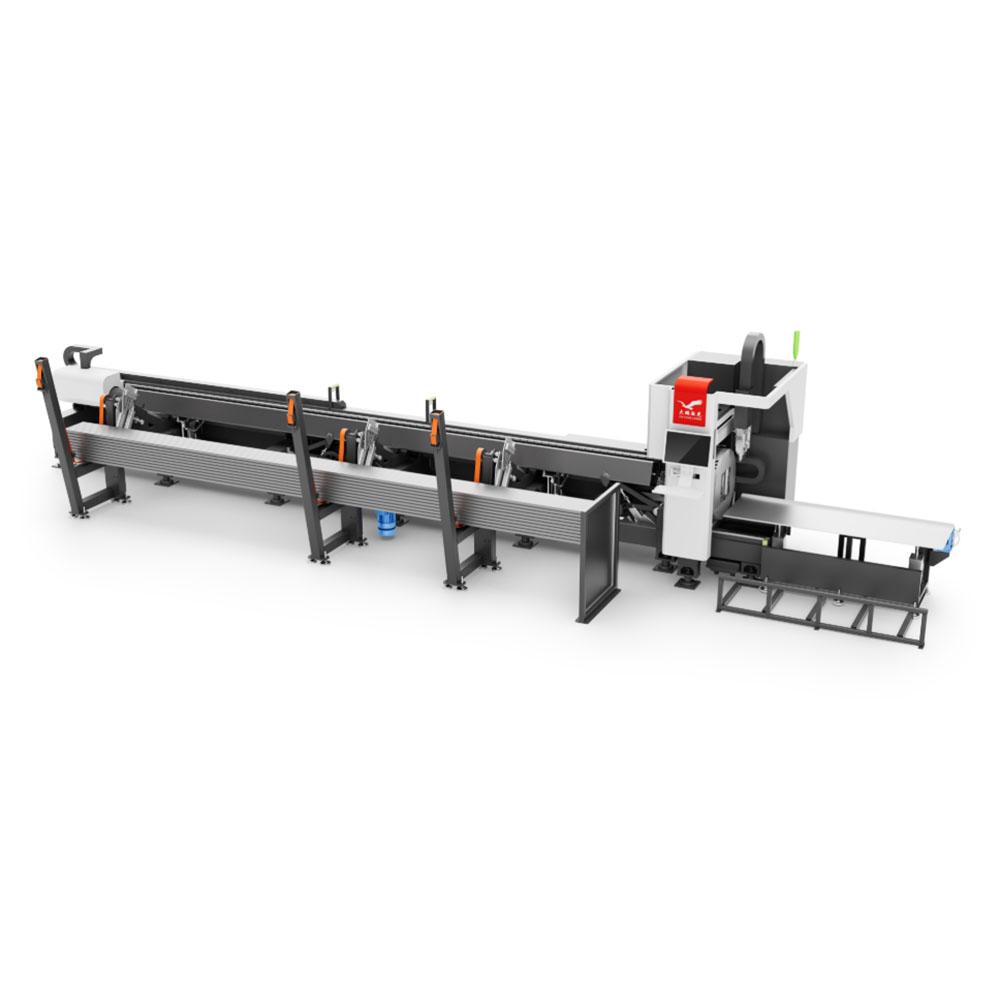

Affordable laser tube cutting machine is an affordable, practical, and versatile tube laser cutter machine. The most productive laser solution for your metalworking. Square and round tube, range min. ∅10 – max.∅240mm.

Features of Professional Pipe Cutting Machine

- Imported high-precision gear rack and linear guide rail ensure smooth transmission and high accuracy. Through laser interferometer, the stability of the machine tool operation and the service life of transmission components are further guaranteed.

- The laser pipe cutting machine adopts a U-shaped beam structure, with the bed using integral square tube and plate mixed welding structure. It undergoes 600°C high-temperature heat treatment, followed by 24-hour furnace cooling and annealing, rough machining, and then vibration aging treatment to completely eliminate welding and processing stress. The machine is processed with a 12-meter gantry milling for semi-rough and finish machining, ensuring good rigidity, high precision, excellent resistance to bending torque, and permanent deformation-free use. The Z-axis adopts an integral cast aluminum structure, lightweight, with quick dynamic response, suitable for high-speed machining and acceleration.

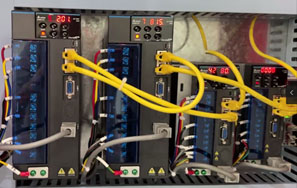

- X, Y, Z, W1, and W2 axes all use Delta high-performance servo motors, characterized by high precision, high speed, large torque, and stable performance, ensuring the machine’s structural stability, good rigidity, light weight, and high dynamic response.

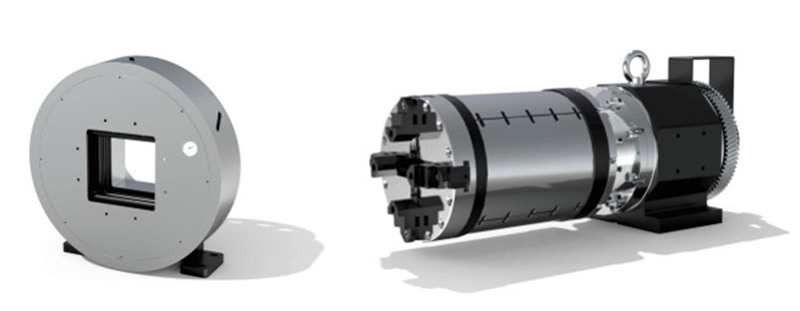

- The front and rear chucks are both four-jawed and pneumatically clamped, moving symmetrically in pairs for automatic centering without the need for manual re-centering. Equipped with pressure regulating valves, the air pressure can be adjusted at any time.

- The feeding area is equipped with a fully automatic feeding system, with the feeding support consisting of variable diameter wheel support components (optional dynamic support and dynamic material receiving). The unloading area is equipped with material receiving inclined plate components. The front chuck is driven by a cylinder for overrun cutting. When cutting large pipes, the rear chuck cannot fully retract into the front chuck. At this time, the front chuck performs overrun cutting, effectively reducing scrap and ensuring precision. Both chucks clamp simultaneously, achieving extremely short scrap (can be as short as 30-80 with layout and process allowance).

- It adopts the FSCUT3000DEM CNC system for dedicated BOCHU fiber laser pipe cutting machines based on the Windows operating system, integrating many specialized laser cutting control function modules, with powerful functions and a user-friendly interface for easy operation.

- The Baichu CNC system FSCUT3000DEM expert edition nesting software is the core technology for achieving “continuous cutting, efficient cutting, and high nesting rate cutting” of CNC cutting machines, fundamentally guaranteeing material savings and improving cutting efficiency.

- The cutting head can be equipped with the fiber laser special cutting head produced by the internationally renowned company, Ospri, and capacitance sensing, characterized by high sensing accuracy, sensitive response, and the most stable and reliable performance.

- Imported high-precision electronic proportional valve from Germany accurately controls the air pressure of cutting auxiliary gas to achieve the best cutting effect.

- The machine is highly integrated with good system performance and high lifespan, featuring high cutting accuracy, low operating costs, and meeting the needs of 24-hour industrial production.

|

|

Laser Source: Raycus Superior beam quality Maintenance-free operation Constant over the entire power range Modular ‘plug and play’ design Large working area, small focal length Compact, robust and easy to install Efficiency > 30% Integrated coupler or beam switch option 2-year warranty |

Laser Cutting Head

|

|

|

Servo Drive

|

| Transmission parts

Higher speeds, higher precision and reliability ensure long and smooth operation. Higher speeds with lower noise volumes ensure high precision and long service life. |

|

Application

This metal tube fiber laser cutting system is widely used to cut various metal pipes and tubes for complex metal parts, prototypes and custom parts in a cost-effective and economical laser cutting capabilities. It is widely used to cut various pipes and tubes, for example, stainless steel, carbon steel, galvanized, aluminum, etc.

Chuck

| Front Clamp | RKQ240 | Back Clamp | RKH240 |

| Single Claw Stroke | 120mm | Single Claw Stroke | 40mm |

| Single Claw Thrust | 76-334kgf | Single Claw Thrust | 136-612kgf |

| Clamping Range | 10-240mm | Clamping Range | 10-240mm |

| Min Clamping Thickness | ≥1mm | Rated Speed (r/min) | ≥1mm |

Fully automatic loading module is optional

Receiving rack module is optional, follow-up support and follow-up receiving are optional

Reviews

There are no reviews yet.