6 Axis 3D Fiber Laser Cutting Robot

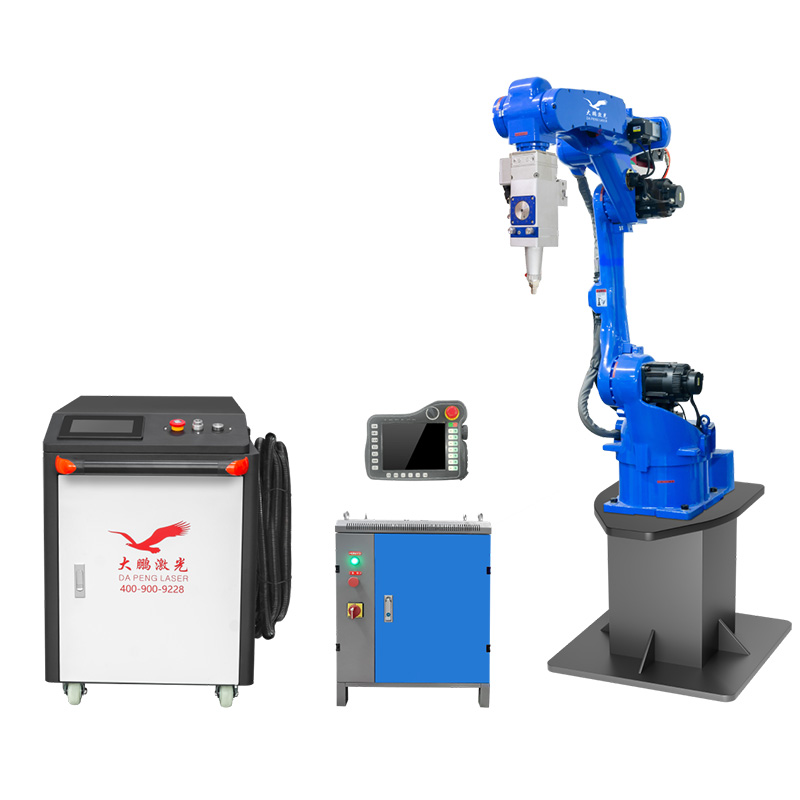

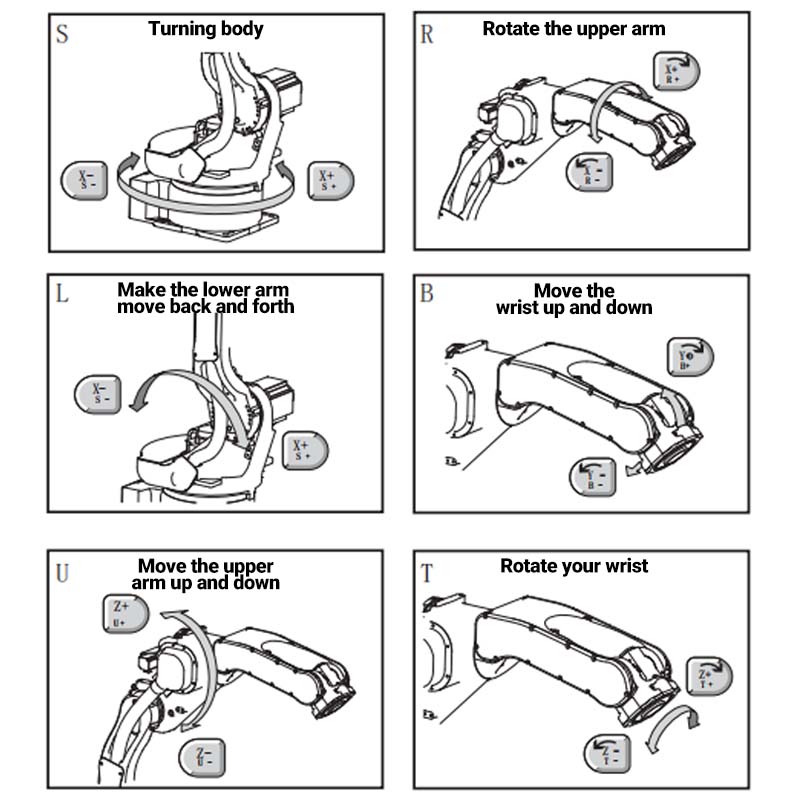

The 6 axis laser cutting robot system integrates a robotic arm with a fiber laser cutting system, making the positioning of the laser cutting head and workpiece more flexible. The robot’s six degrees of freedom enable it to position the fiber laser cutting tool precisely in three dimensions, allowing for the efficient and accurate cutting of complex 3D shapes in a wide range of materials.

- Combining industrial robots with fiber laser technology for 3D cutting, it enables cutting, perforation and edge trimming of sheet metal parts.

- An independently developed PLC system, in conjunction with the flexible and rapid motion performance of industrial robots, allows programming for different products and trajectories. This system is particularly well-suited for processing irregular shapes in automobile 3D components, making it widely applicable in the locomotive manufacturing industry, including locomotive parts, car bodies, door frames, trunks, roof covers, and door edge seats.

- The 3D fiber laser cutting machine has a small footprint, is easy to operate and maintain, and has low maintenance costs. It is an advanced 3D fiber laser cutting device that combines high stability, high precision, high performance, and high speed.

Applications:

The CNC robotic laser cutting is utilized in precision manufacturing to cut complex shapes and intricate patterns in materials such as metal, plastic, and composites. It is especially suitable for drilling and cutting of shell & tubes, and shaped machining of three-dimensional parts, so it is widely used in locomotive manufacturing industries such as automobile parts, bodywork, door frames, roofs, and door window manufacturing to enhance production efficiency and product quality.

Why Choose 3D Robotic Fiber Laser Cutting Machine for Metal?

- 3D Cutting Capability: 3D robot laser cutting machine can efficiently handle complex automotive sheet metal parts, including hoods, rear trunk lids, radiator frames, bumpers, fenders, doors, as well as chassis components like subframes, control arms, rear axles, and more. This capability allows for multi-dimensional trimming and punching operations.

- Avoiding Traditional Processes: Traditional methods such as die stamping, plasma cutting, or five-axis machine tool laser cutting typically require mold manufacturing and numerous processes, while laser cutting robots can reduce these cumbersome procedures and improve efficiency.

- Precise Trimming: Laser cutting robots can perform precise trimming operations, especially when dealing with structurally complex oblique cuts, punches, or folds in large automotive molds. This reduces the need for repeated trial and adjustment, thus reducing the workload for welders.

- Material Compatibility: Industrial laser cutting robots can effectively handle different types of materials, such as alloy steel (e.g., Cr12, Cr12MoV), without the need for multiple welds, reducing the risk of material cracking and mold scrap and lowering production costs.

- Flexibility: Robot laser cutting system offer higher flexibility in the mold-making process, especially in cases of low-volume or prefabrication stages. They can quickly adapt to different design requirements, reducing the cost and lead time for mold development.

Reviews

There are no reviews yet.