With the popularity of new energy vehicles, the demand for lithium-ion batteries continues to increase. To ensure the quality and stability of lithium-ion batteries, precise welding of the battery’s core components is crucial. The commonly soldering methods for lithium batteries include spot welding, wire welding, and laser welding. Among them, spot welding and wire welding are traditional welding methods, while laser welding of EV battery is a new and advanced technology for its high precision and efficiency.

Part 1: Welding Technologies for Lithium Battery

1. Spot welding:

Spot welding is one of the most common welding techniques. It uses resistance heating to weld the electrodes and connecting tabs together by spot welding tongs. Spot welding is fast and provides good welding results, but it requires high surface quality of the electrodes and connecting tabs.

2. Seam welding:

Seam welding involves heating two metal sheets to soften them and then applying tension to connect them. This welding technique is suitable for larger battery components and provides a stronger connection.

3. Laser welding:

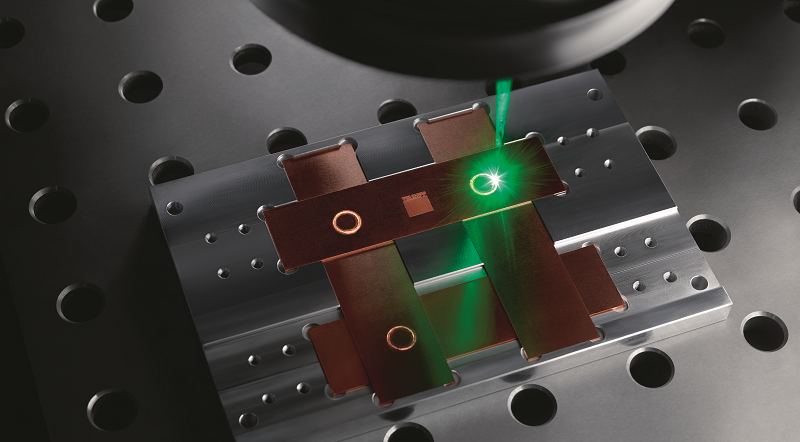

Laser welding uses a high-energy laser beam to instantly melt and connect the electrodes and connecting tabs. Laser welding has the advantages of high welding speed, small heat-affected zone, and high welding quality, but the equipment cost is higher.

4. Tin soldering:

Soldering uses molten solder to connect the electrodes and connecting tabs. This technique is commonly used for soldering small battery components and requires appropriate tin alloys and welding process control.

Spot welding, wire welding and laser welding are commonly used welding techniques for new energy batteries. According to specific a requirements, choosing a suitable welding method to ensure the quality and performance of the battery pack.

Part 2: Why Use Laser Welding for Lithium Ion Battery Pack?

Laser welding is a process that utilizes the exceptional directionality and high power density of a laser beam. It works by focusing the laser beam onto a small area using an optical system, creating a highly concentrated heat source at the welding spot within an extremely short period of time. This concentrated heat source melts the materials being welded, resulting in the formation of strong welds and seams.

Laser welding is increasingly used for lithium ion battery pack manufacturing for eight reasons:

High welding speed:

Laser welding has a faster welding speed. Laser welding is a high-speed welding process, which is important for the mass production of battery packs otherwise, the production process could take too long and limit production numbers.

High precision:

Laser welding is a precise method of joining metal parts, resulting in a consistently high-quality bond. With laser welding, weld penetration depth and weld width can be easily controlled and modified to achieve the desired results. The welding strength is high, and the resistance, air tightness and mechanical properties of the welding point are good. This is critical to the performance and reliability of the electric vehicle battery.

Non-contact reduced damage:

Laser welding is a non-contact welding technology that does not directly contact the battery components during welding, reducing the risk of damage and deformation of the battery components. This is very important to maintain the integrity and consistency of battery packs. Laser welding creates less heat and causes minimal damage to the battery cells.

Improved conductivity:

The electrical conductivity of an e-mobility battery is critical to its performance. Laser welding uses a high-energy laser beam to melt the welded joint in an instant, enabling high-quality conductive connection between the electrode and the connecting piece. Laser welding can ensure low resistance and stable current transfer, improving the electrical conductivity of the lithium battery packs.

Dissimilar metal welding:

Lithium-ion batteries often involve different kinds of metal materials, such as copper, aluminum and nickel. Laser welding can realize the welding of different kinds of metals, because its high energy density can overcome the interface reaction between metals. This makes laser welding ideal for welding dissimilar metals.

Surface contaminant treatment:

During battery manufacturing, there are often contaminants, oxides or coatings on the surface of electrodes and tabs. These contaminants and oxides can negatively affect weld quality. Laser welding has high-energy local heating, which can remove surface contaminants by melting and evaporating, providing a clean welding surface, thereby ensuring the quality and reliability of welding.

Automation and flexibility:

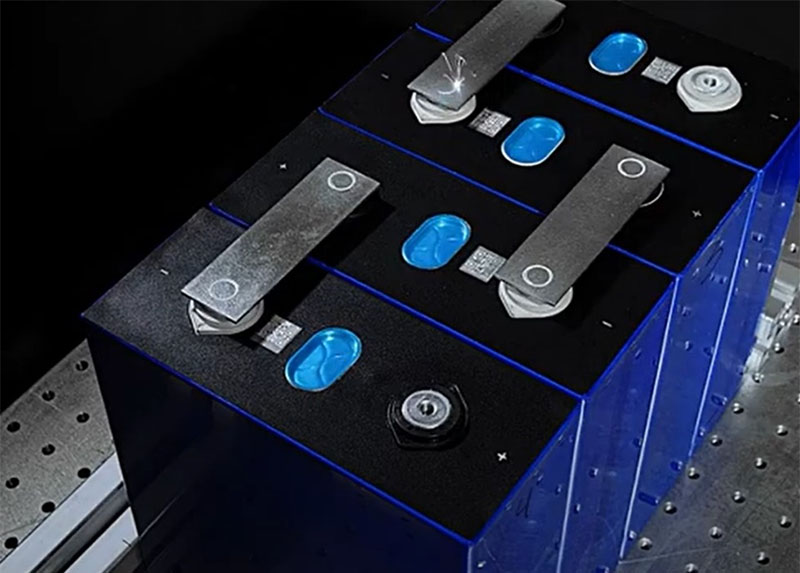

Lithium battery laser welding machine can be integrated with automated production lines which can help reduce manual labor, ensuring a more consistent and efficient production process. At the same time, laser welding can also adapt to battery components of different sizes and shapes, with strong flexibility.

In the entire new power batteries industry, laser welding as a high-precision welding method, is extremely flexible, precise and efficient, and can meet the performance requirements in the production process of batteries. At present, it has become the essential equipment for li ion battery welding.

The Advantages of Battery Laser Welder

Resistance welding, laser welding and Micro TIG welding are the main welding techniques in battery manufacturing. And what are the advantages of using laser welding for lithium ion battery packs?

Welding Speed:

Resistance welding has a fast welding speed, which can achieve efficient production. Laser welding also has a faster welding speed, but may be more delicate and complex than resistance welding. The welding speed of micro argon arc welding is relatively slow, and it is suitable for situations that require high welding quality.

The Galvo lithium battery laser welding machine has high welding efficiency, which is at least 3 times higher than that of ordinary laser welding machines. The flexibility of our laser equipment fits the battery design and enables the production of more powerful batteries. There are many configurations and options that you can choose to customize and use into your electric vehicle battery production line.

When choosing laser welding for battery, both pulsed and continuous mode are viable options, depending on the application needs and welding requirements. You can refer to this article: Introduction of EV battery laser welding process to know pulse and QCW laser welding machine for battery pack.

Welding Quality:

Laser welding has the characteristics of small heat-affected zone and fine weld seam, which can achieve high-quality welding. Resistance welding results may be affected by the surface quality of electrodes and lugs. Micro argon arc welding can achieve a solid connection, but the welding heat is relatively large, which may have a certain thermal impact on the surrounding area.

Equipment cost: The cost of Battery Laser Welding Machine is relatively high and requires a large investment. Resistance welding & micro argon arc welding equipment is relatively common and affordable.

Part 3: Laser Welding Applications in Battery Pack Assembly Lines

Laser welding technology is mainly used in the manufacture and connection of batteries, as well as the manufacture of battery casings.

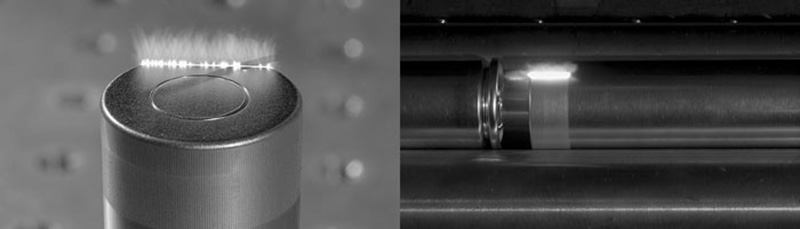

1. Laser Welding Battery Cells and Battery Tab

There are usually three materials for battery tabs. The positive electrode of the battery uses aluminum (Al) material, and the negative electrode uses nickel (Ni) material or nickel-plated copper (Ni-Cu) material. In the manufacturing process of lithium batteries, one of the process is to weld the battery tabs and poles together. Welding not only needs to ensure reliable connection between tabs and poles, but also requires smooth and beautiful welds. Choosing the fiber laser with good beam quality and uniform energy distribution to achieve aluminum-aluminum and copper-copper structure welding stability of the electrode column, reduce spatter, and improve welding quality and efficiency.

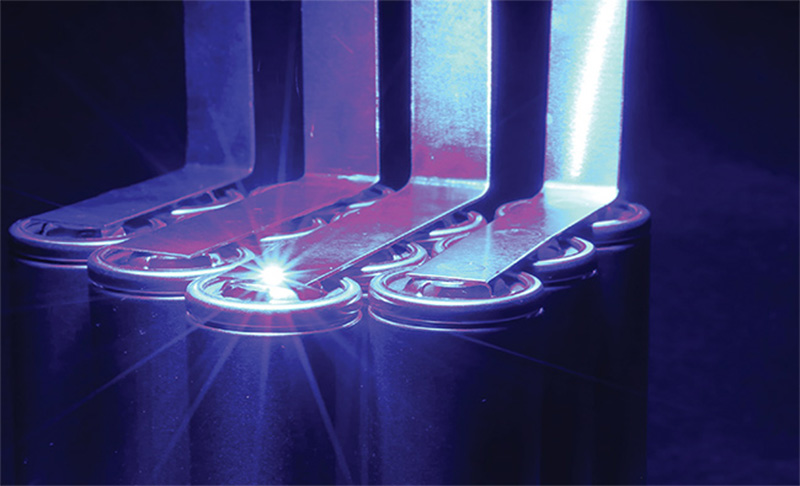

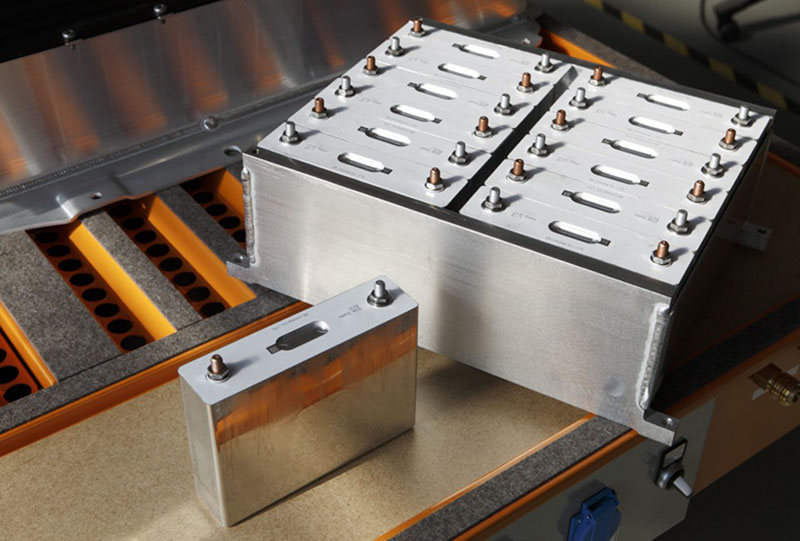

2. Lithium Battery Module and Pack Soldering

The series and parallel connection between power batteries is generally completed by welding the connecting piece and the single battery. The positive and negative electrodes are made of different materials, generally copper and aluminum.

The adapter piece and the tab are the key components to connect the battery cover and the battery cell. Copper to copper and aluminum to aluminum are using laser welding. At the same time, since both copper and aluminum conduct heat very quickly, and have very high reflectivity to laser light, and the connecting pieces are thicker, it is suitable to use a high power laser for welding.

3. Laser Welding the Lithium Battery Case

The casing materials of the lithium battery include aluminum alloy and stainless steel, among which aluminum alloy is the most used. The processing and joining of these materials also requires laser welding technology. Pre-welding of the battery pack into the shell, sealing welding of the top cover of the shell, sealing welding of the liquid injection port, etc. Stainless steel is the most suitable material for laser welding, especially 304 stainless steel, whether it is pulsed or continuous laser, it can obtain welds with good appearance and performance.

Using a continuous laser to weld the lithium battery casing can increase the efficiency by 5~10 times, and the appearance and sealing are better. Laser welding machines can provide high-efficiency and high-precision welding in the manufacture of battery casings.

Part 4: Application of Laser Technology to Batteries Production

Laser Welding

Laser welding technology has been widely applied in the new energy vehicle and battery industries. Many well-known international companies, such as Tesla, LG, BYD and Panasonic, have adopted laser welding technology in their production lines. The application of laser welding technology not only enhances the production efficiency and quality of new energy lithium batteries but also promotes technological innovation and industrial advancement in the electric cars and battery industries.

Laser Cleaning

Regardless of whether it is paint, oil, grease, or smoke residue, battery manufacturers should ensure that the surface of the battery pack is thoroughly clean before and after welding. High-power laser cleaning machines are an ideal choice because they can quickly, uniformly, and precisely remove coatings, paint, electrolytes, and oxides from metal surfaces to improve welding quality.

Laser Marking

Fiber laser marking machines provide high contrast, soft and permanent marking on lithium battery pack, such as clear QR or part identification codes. They can also easily print brand logos and nameplate, further enhancing brand influence.

Cost of Battery Laser Welding Machine

The equipment can be expensive to acquire, operate and maintain. However, it is a viable and cost-effective option to consider having a laser equipment manufacturer offer a laser welding solution for your power battery production line. Price usually depends on laser welding machine configuration and quantity. Please consider improving your battery manufacturing efficiency, quality and saving labor from now on.

The Bottom Line:

With the continuous expansion of the lithium battery market, the battery manufacturing technology is also constantly developing and upgrading. As a high-precision, high-efficiency, and high-stability welding method, EV battery laser welding will become an important trend in lithium battery electrode welding. As a well-known battery laser welding machine manufacturers and suppliers, DPLASER will provide more high-quality and efficient battery laser welding solutions for the production of lithium batteries.