Laser marking technology has become an indispensable tool in the medical industry, revolutionizing the way surgical instruments and medications are identified and traced. In this blog post, we will learn applications of laser marking for medical, particular emphasis on its role in marking surgical instruments and medicines. By understanding the reasons behind the widespread adoption of laser marking machines in healthcare, we aim to provide valuable insights to guide you in selecting the most suitable medical laser marking machine for your specific needs.

Laser Marking Surgical Instruments

According to international regulations governing the registration of medical devices, each medical device must bear a Unique Device Identification (UDI) code to ensure traceability. These identifiers must possess durability, clarity, and recognizable.

However, in cases where certain medical devices undergo frequent reuse and processing hundreds of times, often with strong alkaline detergents and high-temperature steam sterilization, how can highly identifiable, clear, and durable UDI codes be imprinted on them? Laser engraving machine offers the perfect solution for medical devices in such scenarios.

Why Use Laser Marking in the Medical Industry?

Laser marking finds significant application in the pharmaceutical and medical device sectors. Firstly, its non-contact operation minimizes the risk of cross-contamination, contributing to the cleanliness maintenance of medical supplies. Secondly, its high precision enables the creation of intricate markings, ideal for precise identification of medical equipment and products. Moreover, laser marking’s durability and resistance to wear ensure long-lasting and reliable markings, meeting the prolonged usage demands of medical supplies.

Readable Markings: Laser engraving machines can create permanent, high-contrast markings on medical equipment, ensuring clear visibility of Unique Device Identification (UDI).

Durability: Medical equipment is often used in humid, acidic, or alkaline environments, requiring good corrosion resistance. Laser marking preserves the corrosion resistance of medical equipment surfaces, extending their lifespan and ensuring performance stability.

Non-contact: The non-contact nature of laser marking machines is particularly advantageous in the medical supplies industry. By utilizing laser technology, the marking process for medical equipment and products does not involve physical contact with the surface being marked. This feature is crucial for maintaining the integrity and cleanliness of medical supplies, as it eliminates the risk of contamination that can occur with traditional marking methods involving physical contact.

High Precision: The precision provided by laser technology enables intricate markings to be achieved, ensuring that even the most delicate medical instruments and devices can be accurately marked without compromising their integrity.

Permanent Markings: Laser interacts directly with the material surface to create permanent markings. Such durability is crucial for long-term use of medical equipment, ensuring lasting readability of identification information and avoiding identification difficulties due to fading or damage.

Maintaining High Contrast: Parameters can be adjusted during laser marking to ensure markings have high contrast. This is crucial for ensuring clear visibility of markings and improving identification accuracy. Furthermore, maintaining high contrast helps reduce the risk of identification errors, enhancing the safety of medical equipment.

Compliance with Regulatory Requirements: Medical devices must comply with strict regulatory requirements, including device tracking, management, and maintenance. Laser marking can label a unique UDI on devices, ensuring compliance with regulatory requirements throughout their lifespan, thereby enhancing the safety and compliance of medical equipment.

Laser marking and engraving bring numerous advantages to the medical device industry, including high precision, permanent markings, non-contact processes, and compatibility with various materials. This technology is widely adopted for its ability to meet regulatory requirements, enhance patient safety, and ensure product integrity.

In the medical industry, common types of laser marking machines include CO2 laser marking machines, fiber laser marking machines, picosecond laser marking machines, and UV laser marking machines. UV laser marking machines are particularly suitable for applications requiring high precision, such as the marking of medicine capsules and infusion tubes. Medical devices are typically made of materials such as metal, plastic, and glass, and they require unique Device Identification (UDI) codes for tracking product information and improving traceability.

Application of Laser Engraving for Medical Equipment

Laser Marking Surgical Instruments

Surgical instruments and instrument packaging require clear identification for proper use and management during surgical procedures. Laser marking technology can permanently mark key information such as model numbers, batch numbers, and sterilization information on the surface of instruments or packaging.

Medical Devices

Laser marking machines can be used to permanently mark important information such as manufacturer details, product models, serial numbers, and production dates on medical devices, which are crucial for product traceability and quality control.

Medical Implant

Medical implants typically require identification of production dates, batch numbers, manufacturer information, etc., to ensure compliance with safety standards and quality requirements before implantation into the human body. Laser marking is a permanent identification method that ensures the accuracy and longevity of this identification information.

Drug Packaging

Traditional drug packaging marking involves direct printing on packaging materials, which can easily lead to fading, peeling, or tampering of product information. Laser marking, as a non-contact, non-polluting identification method, can meet the needs of various medicine package and the drug surface. The markings are not easily erased or tampered with, providing anti-counterfeiting measures and ensuring the traceability of drug information.

Medical Catheters

Laser engraving machines can also be used for identification on infusion tubes and subcutaneous injection needle heads. Traditional inkjet marking poses a risk of contaminating the product, whereas laser marking achieves clean marking on products without contamination or damage, ensuring the safety and reliability of infusion tubes and improving the efficiency and safety of medical devices.

Medical supply manufacturing requires a very high level of product quality and labeling, as medical products are directly related to people’s health and lives. In order to meet these high standards, manufacturers need to use advanced technology and equipment to ensure the quality and safety of their products.

As an advanced manufacturing technology, laser marking equipment has been widely used in the production and manufacturing of medical supplies. Its main advantages include high precision, high efficiency, non-contact processing, and other features that enable precise marking and engraving on a wide range of materials with long-lasting and durable marking quality. This makes laser marking machine one of the indispensable tools for medical manufacturers.

Despite the high price of laser marker, the return on investment is substantial in the long run. Firstly, combined with assembly lines, laser marking equipment can significantly improve productivity and product quality, reducing labor costs and production errors, saving time and resources. Secondly, by ensuring clear and durable product marking, it helps to enhance product image and market competitiveness, which in turn increases sales and market share. In addition, laser marking system has a long service life and stable performance, which can bring sustained benefits to manufacturers.

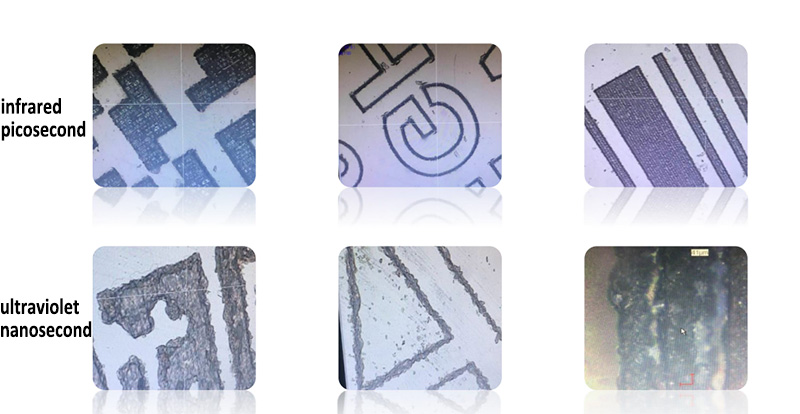

Picosecond Laser Marking Machine – Medical Instrument Marking

Medical picosecond laser marking machine is a commonly used laser marking equipment in the medical industry. It utilizes picosecond ultra-short pulse laser technology, which is mainly used for precise, high-quality marking of various medical metal instruments and plastic products. Its ultra-short pulse width allows for extremely high peak power and precise control, making it particularly suitable for creating long-lasting, clear, micron-sized graphic or text markings on material surfaces without thermally affecting the microstructure of the object being processed.

The pico laser marking machine can create color marking on titanium and black marking on anodized aluminum oxide and stainless steel. These are commonly used materials for medical devices, so it is very suitable for medical industries marking.

All device identifiers for medical devices, implants, tools, and instruments must be permanently, clearly and accurately marked. This characteristic is important for traceability and transparency of medical products and devices, ensuring that they can be properly tracked and identified throughout their lifecycle. Picosecond laser black marking is widely used in medical implants, surgical instruments and disposable. Therefore, the picosecond laser marking machine is an ideal tool for enhancing quality control, traceability, and safety in the medical industry.

Why Use Picosecond Laser Marking Machine in the Medical & Pharmaceutical Industry?

High Precision: Picosecond lasers are known for their ultra-short pulse width, enabling Nano-level micromachining on material surfaces and providing extremely high marking resolution and precision. Therefore, it is particularly suitable for complex graphics and small font marking on small, precision medical instruments.

Fast Marking Speed: This equipment adopts advanced laser technology, with efficient marking speed, significantly shortening the production cycle and improving production efficiency.

Deep Color Marking: Picosecond lasers can achieve deep black marking on a variety of materials, with high contrast and excellent visual effects, meeting the long-term stability requirements of medical devices.

Adjustability: Users can adjust laser parameters such as power, frequency, and focal length according to different marking requirements, accurately controlling the depth and width of the marking. This ensures the durability of the marking while avoiding excessive damage to the material surface, without affecting the function and safety of the instruments.

Wide Material Adaptability: The equipment is not only suitable for metal materials (such as stainless steel, titanium alloys, etc.) but also for marking on plastics, ceramics, and other non-metal materials, widely used in various medical metal and plastic products.

High Stability and Reliability: The equipment adopts advanced laser technology and stable mechanical structure design, ensuring long-term stable operation and reducing maintenance costs and downtime.

Ease of Operation: The equipment has a user-friendly operation interface, simple and easy to understand operation, even non-professionals can easily get started, saving training costs and time.

Laser marking medical devices are used to create permanent, high-contrast marks on medical instruments and medical products. Femtosecond laser marking and picosecond laser marking are two advanced short-pulse laser technologies that provide extremely high-precision marking with excellent contrast.

Femtosecond Laser Marking & Picosecond Laser Marking

Femtosecond lasers are known for their extremely short pulse widths (down to the femtosecond level, i.e., 10^-15 seconds), which allow for extremely fine and virtually non-destructive processing on the surface of, or within, materials. In marking applications in the medical industry, femtosecond lasers create deep black marks with excellent contrast, thanks to a “cold processing” process that produces little heat diffusion, thus avoiding thermal effects on the surrounding material and resulting in clearer and more durable marks. This feature is particularly suitable for thermally sensitive and biocompatible medical materials.

Although the pulse duration of picosecond lasers is slightly longer than that of femtosecond lasers, they are still in the ultra-short pulse range, which produces less heat effect during processing. In medical labeling applications, picosecond lasers also meet the need for precision labeling of high-quality medical products.

While femtosecond lasers are generally considered to provide the best high-contrast marking results, picosecond lasers are a little less impressive, but also provide excellent marking solutions. Both technologies represent advanced applications of laser marking for the ever-increasing demands for refinement, standardization and safety in the medical industry.

Conclusion:

Laser marking in the medical industry provides critical support for the identification, traceability and quality control of medical devices. Picosecond laser, as an advanced short-pulse laser technology, provides a reliable solution for the precision marking needs of medical devices, and its high-contrast and high-precision marking effect greatly improves the recognizability and safety of products. With the continuous progress and innovation of technology, laser marking will continue to play an important role in the medical field, bringing more opportunities and challenges to the development of the medical device industry.