In the modern realms of manufacturing and design, the rise of laser technology has opened new possibilities for creators and manufacturers. This article, we will thoroughly compare difference between laser cutting and laser engraving, analyzing their respective characteristics and applicable scenarios. Whether you are pursuing precision cutting or seeking deep engraving, by contrasting the advantages of these two, we aim to assist you in making informed decisions and harnessing the full potential of laser technology in your projects.

Laser cutting machines and laser engraving machines both utilize laser energy to melt materials and shape them into desired forms. While their functions are similar and are often confused, they have distinct differences. The main distinctions of the laser cutting vs laser engraving include:

Difference Between Laser Cutting & Laser Engraving

Working Principles:

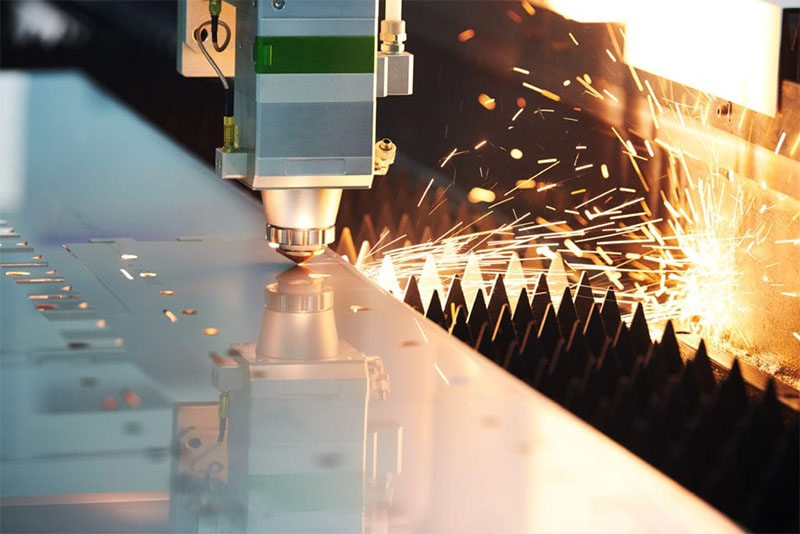

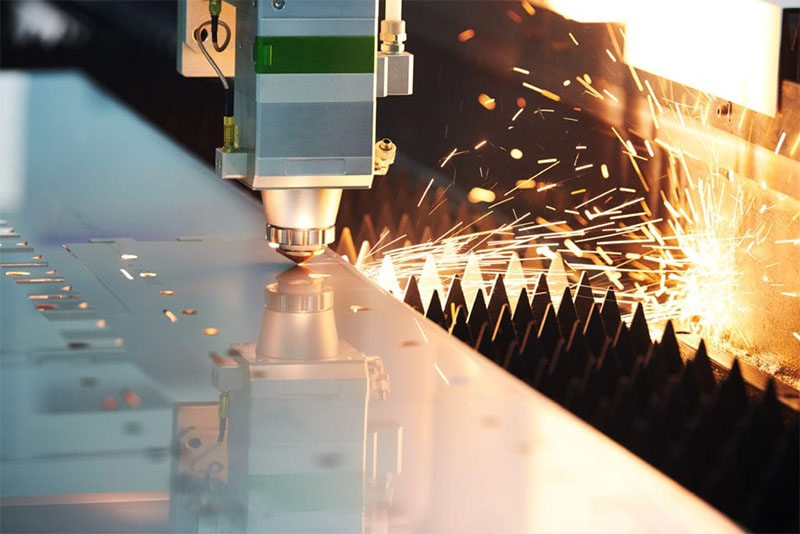

– Laser cutting utilizes a high-energy density laser beam to locally evaporate, melt, or oxidize materials. By controlling the position and movement speed of the laser beam, cutting of the material is achieved. The device achieves its purpose by using laser-induced high-temperature melting for a thorough cut. The temperature at the focus of laser cutting is very high, and the beam transforms the material, causing it to melt, oxidize, or vaporize, forming a cut line. The cut surface is typically relatively smooth along the vertical cutting edge.

– Laser engraving, on the other hand, utilizes the high-energy density of a laser beam to create small oxidation, scorching, or vaporization effects on the material’s surface, achieving the engraving of patterns, text, and more. The device achieves its purpose by using laser-induced high-temperature melting for engraving without cutting through. Laser engraving presents fine and precise markings with richer patterns and textures. The depth and width of the engraving can be adjusted based on laser parameters.

Power Difference:

The laser engraving machine typically has a smaller power, ranging from a few hundred to around one thousand watts. In contrast, the laser cutting machine has a much larger power range, with lower-power laser cutting machines starting at 1000W and larger ones reaching tens of thousands of watts, suitable for cutting thick metals.

Cutting Depth:

The main difference between engraving and cutting lies in the depth. Laser cutting machines can be configured to achieve the desired depth for engraving or cutting.

Laser engraving machines can also be used to cut relatively thin workpiece. The engraving depth for metals is typically around 0.020 inches, and the cutting depth depends on the material hardness and the rated power of the laser marking machine. However, due to the smaller power of laser engraving machines, they may not achieve effective cutting for thicker work pieces.

Design File Formats:

Laser cutting machines use vector design files, while engraving machines use both vector and raster design files.

Vector design formats are suitable for laser processing that requires fine lines. It involves using the laser beam to trace the straight lines and curves of the design vectors individually. Vector design files can be in formats such as EPS, AI, or CDR.

Raster design formats are suitable for laser processing materials like wood, stamps, and paper. It involves constructing the design from pixels and engraving it line by line or point by point. Raster files are in JPG or PNG formats.

Price:

The price of laser cutting machines varies widely due to differences in lasers and accessories, ranging from tens of thousands to several hundred thousand. In contrast, laser engraving machines with lower power are much cheaper compared to laser cutting machines.

Size and Application:

| Laser Cutting Machine: | Laser Engraving Machine: |

| Typically designed on a larger scale to accommodate sizable workpieces. These machines are primarily used for cutting various materials, including metals, wood, and plastics. They are commonly employed in industrial and manufacturing settings due to their robust cutting capabilities. | Generally designed as desktop models, compact and lightweight. Machines of this nature are suitable for engraving smaller-sized items such as crafts, signage, toys, etc. Laser engraving machines prioritize fine and precise engraving work rather than large-scale cutting. |

Laser Cutting vs Laser Engraving for Metal

Application for Different Materials:

In general, laser cutting machines have higher power, often equipped with CO2 and fiber laser sources, allowing them to process a wider range of materials.

Fiber laser cutting machine is suitable for thicker materials, including metals, alloys, plastics, and organic glass. It is particularly well-suited for precise and rapid cutting of metal materials.

Metal materials include stainless steel, aluminum, copper, iron, etc. Non-metal materials include PVC, acrylic, density board, wood, etc. Materials that can be processed by laser cutting include metals, acrylic, density board, wood, etc. In comparison, laser engraving machines can handle thinner portions of metals, alloys, acrylic, density board, wood, KT board, and similar materials.

Difference between Laser Engraver and Laser Cutter

Laser Cutting:

Purpose:

Primarily used for precise shaping and cutting through metal materials to create accurate components.

Process:

The laser beam is focused on the metal surface, and under the high-temperature action of the laser, the metal evaporates or melts, achieving precise and clear cutting along a predetermined path.

Applications:

Widely used in manufacturing, automotive, aerospace, and metal fabrication industries for producing complex metal components, parts, and prototypes. Applicable to various materials, including metals, plastics, wood, etc.

Laser Engraving:

Purpose:

Generally used for non-metal materials such as wood, leather, paper products, and plastics. It can also engrave some metal surfaces with suitable coatings.

Fine Engraving:

Laser engraving can achieve very detailed engraving effects, suitable for applications with high requirements for patterns, text, etc.

Flexibility:

Different effects can be achieved by adjusting the laser’s intensity and engraving depth, providing high flexibility.

Non-contact:

Similar to laser cutting, laser engraving is a non-contact processing method that does not damage the surface of the workpiece.

Applicable to Various Materials:

Laser engraving can be used for various materials, including wood, plastics, glass, etc.

Material Removal: Laser cutting forms shapes by cutting through the material, while laser engraving forms markings by removing surface material.

Purpose: Cutting is used for manufacturing components, while engraving is used for decoration and identification.

Depth: Cutting is typically deeper, while engraving is surface treatment.

Applications: Laser cutting is primarily applied to achieve functional parts, while laser engraving focuses more on aesthetics and identification. In the case of metal materials, laser cutting is commonly used in the manufacturing sector, while laser engraving is more suitable for identification and decoration purposes.

Laser Cutting vs Laser Engraving for Woodworking

Using CNC laser cutting and engraving on wood depends on factors such as the type of wood, hardness, and other parameters like humidity or texture. The more uniform the color and texture of the wood, the better and more uniform the laser engraving effect.

During laser cutting, the laser beam passes through the wood, rapidly evaporating excess debris to ensure clear and clean cutting edges. CNC laser cutting is well-suited for woodcraft projects requiring high precision and detail, such as puzzles, decorations, or architectural models.

For laser engraving, consistent engraving can produce patterns with specific depths, resulting in subtle transitions and gradient colors. By adjusting the engraving depth, different levels of engraving effects can be achieved, ranging from shallow to deep, meeting various design requirements. Deep engraving is often used in the creation of wooden artworks, signs, or personalized gifts.

Adjusting the intensity and engraving depth of the laser can yield different effects, making the engraving process more flexible. This allows for the creation of more three-dimensional and rich effects on the wood surface. Additionally, by controlling the laser’s movement path and intensity, different depths and details of engraving can be achieved to meet specific design needs.

Can I Use Laser Cutting Machine for Engraving?

Yes, laser cutter are generally capable of engraving. Laser cutting machines use a high-energy laser beam to cut or vaporize materials, and this technology can create patterns, text, or designs on different types of materials. In some cases, by adjusting parameters, using appropriate lenses, and adjusting focus, simple engraving effects can be achieved.

Laser cutting system are primarily designed for cutting materials rather than engraving. Laser engraving machines are specialized for creating patterns, text, or designs on the surface of materials. For dedicated engraving tasks, it is usually recommended to use a laser engraving machine specifically designed for that purpose.

Application Areas:

Laser cutting has a wide range of applications, including but not limited to the metal industry, automotive manufacturing, electronics manufacturing, aerospace, and more. In these fields, laser cutting can be used to cut metal plates, tubes, parts, etc., with the advantages of high precision, speed and low cost. Laser cutting is usually faster than laser engraving.

Laser engraving also has a wide range of applications and is mainly used in the fields of art, handicrafts, gifts, signs, and decorative materials and so on. In these fields, laser engraving can be used to produce various patterns, text, images, etc., with the advantages of high precision, good effect, fast speed and so on. In addition, laser engraving can also be used in the fields of container printing, leather texture processing, wood product engraving, etc., which can improve production efficiency and reduce costs.

Advantages & Disadvantages: Laser Cutting vs Laser Engraving

| Laser Cutting: | Laser Engraving: |

| High Precision: Laser cutting achieves extremely high cutting precision, suitable for materials requiring fine processing and complex shapes.Fast: The laser cutting process is relatively fast, enabling the completion of large-scale production in a short time.Non-contact: Laser cutting is a non-contact processing method that avoids physical contact, preventing damage to the surface of the workpiece.Applicable to Various Materials: Laser cutting can be used for cutting a variety of materials, including metals, plastics, wood, etc.High Initial Investment: The purchase and maintenance costs of laser cutting equipment are relatively high, which may be a burden for startups. | Fine Engraving: Laser engraving excels in producing intricate and detailed engraving effects, making it well-suited for applications demanding high precision in patterns, text, and other intricate elements.Flexibility: The flexibility of laser engraving lies in its capacity to adjust the intensity and engraving depth of the laser, allowing for the attainment of diverse effects and providing a high degree of flexibility.Applicable to Various Materials: Laser engraving is applicable to a variety of materials, including wood, plastic, glass, and more.Relatively Slow: Compared to laser cutting, laser engraving has a relatively slow processing speed and may not be suitable for large-scale production.Material Thickness Limitation: For thicker materials, laser engraving may require a longer time to complete, and the effect may not be as pronounced as laser cutting. |

| Laser cutting focuses more on separating materials quickly and accurately, while laser engraving emphasizes detailed marking and pattern outlining on surfaces. Different application scenarios determine the differences in material selection, process principles, cutting results, and application areas. Laser engraving can produce more detailed and complex designs than laser cutting. | |

Laser Types for Laser Cutting and Engraving

The choice of laser source for laser cutter and laser engraver primarily depends on the application requirements and the nature of the processed materials.

Laser Cutting:

CO2 Laser: CO2 lasers are the most common type for laser cutting, suitable for most non-metal materials such as wood, plastics, paper, and fabrics. They operate in the infrared region with a typical wavelength of 10.6 micrometers.

Fiber Laser: In the field of metal cutting, fiber lasers excel. They are primarily used for cutting metals such as carbon steel, stainless steel, aluminum, and copper. Fiber lasers have a high photoelectric conversion efficiency, making them suitable for high-precision and rapid cutting of metals.

Laser Engraving:

CO2 Laser: Similar to laser cutting, CO2 lasers are widely used for laser engraving. They are suitable for various non-metal materials, including wood, leather, fabrics, and plastics.

Fiber Laser: In some cases, fiber lasers can also be used for laser engraving, especially when there are specific requirements for metal engraving.

UV Laser: For certain special materials such as some plastics and transparent materials, UV lasers may be more suitable, with typically shorter operating wavelengths.

Whether you need to cut thick materials like wood or engrave glass, laser technology can meet your requirements. With DPLASER laser cutting and laser engraving systems, you can enhance the efficiency and quality of your manufacturing production. As technology continues to advance and applications expand, laser processing technology is poised for broader prospects of development.