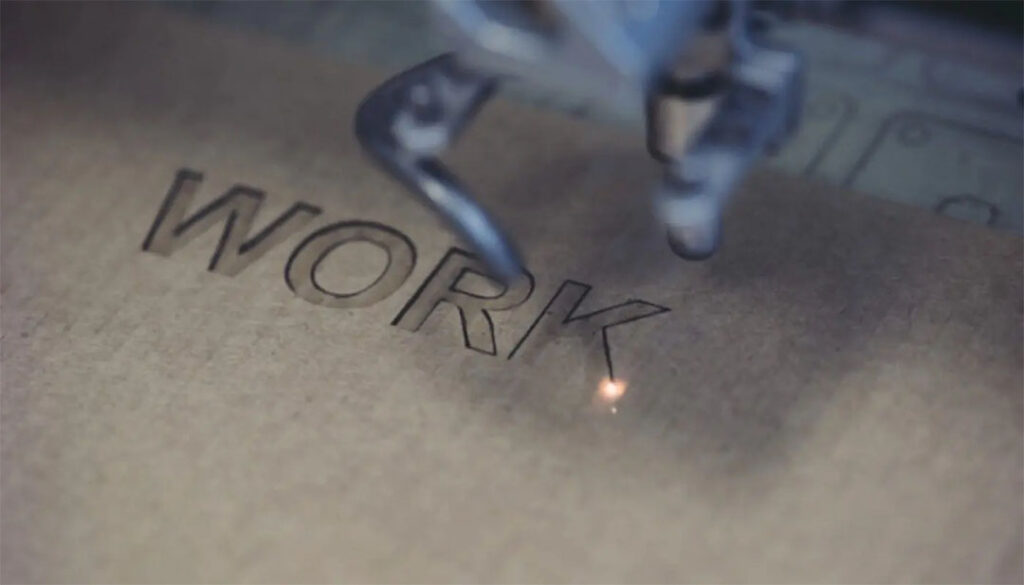

With its unparalleled precision, laser equipment shines in cutting many types of materials. Nowadays, with the leap of technology, laser engraving process is not only limited to ultra-high precision cutting, but also expanded to diversified application scenarios, such as precision cutting, fine marking, micro-drilling and deep engraving, etc., which greatly improves the manufacturing efficiency and the possibility of artistic creation. When choosing a laser engraving machine, it is vital to make the right choice for your engraving needs. In this article, we will explore what is the best laser engraving machine for metal? We will take an in-depth look at the various types of laser engravers and laser engraving accessories, and provide expert guidance to help you find the best engraving machine for your needs.

What Are the Different Types of Laser Engraving and Marking Machines?

1. Fiber Laser Marking Machine: Fiber laser marking machines utilize fiber laser sources to generate high-intensity laser beams. These machines are renowned for their high-speed marking capabilities and are commonly used for marking metal materials such as stainless steel and aluminum. Fiber laser marking machines are also highly reliable and require minimal maintenance.

2. CO2 Laser Engraving Machine: CO2 laser engraving machines use carbon dioxide lasers to engrave or cut materials. These machines are typically employed for engraving wood, acrylic, leather, and other non-metal materials.

3. UV Laser Marking Machine: UV laser marking machines utilize ultraviolet laser sources to create markings on various materials, including plastics, glass, and ceramics. These machines offer high efficiency and excellent marking quality, making them popular in industries such as electronics, medical devices, and cosmetics. UV laser marking machines are also known for their ability to mark transparent materials without causing damage.

How to Choose Laser Engraving Machine?

Laser engraving systems have become indispensable when it comes to personalizing items or adding intricate designs to a variety of materials. Choosing a laser engraver that perfectly fits your specific needs, budget and workspace constraints ensures that your investment results in accurate, efficient and high-quality engraving every time.

Material Compatibility: One of the most important factors to consider is the compatibility between the machine and the materials you plan to mark or engrave. Different machines are designed to handle specific materials. For processing organic materials like wood, glass, paper, or leather, you will need a CO2 laser. For marking metals or plastics, a fiber laser is required. Consider the thickness, hardness, and composition of the materials to ensure compatibility.

Marking or Engraving Depth: Depending on your requirements, you may need a machine capable of creating shallow marks or deep engravings. Some machines offer adjustable settings, allowing you to achieve different depths according to the application. Ensure to assess the marking or engraving depth capability of each machine you’re considering.

Speed and Productivity: The speed at which a machine marks or engraves materials is an important consideration. Look for machines that offer fast marking speeds without compromising accuracy and quality. Additionally, consider productivity features of the machine, such as automatic loading and unloading systems, to maximize efficiency.

Worktable Size: The worktable size of a laser engraving machine is a key factor in equipment selection as it directly impacts the size of materials that can be processed and production efficiency. A larger worktable means it can accommodate larger workpieces, suitable for handling large projects like furniture decoration panels, signage production, or industrial part marking. Even when dealing with small workpieces, a larger worktable offers more layout flexibility, allowing simultaneous fixation of multiple small pieces for batch processing, thus enhancing production efficiency.

Dual-head laser marking machines enable more efficient multitasking parallel processing. Each laser head can work independently, targeting different areas or engraving multiple identical or different workpieces simultaneously, significantly reducing the production cycle, especially in large-scale customization or high productivity requirements.

Attachment for Laser Engraving & Marking

Optional accessories for laser marking machines aim to achieve optimal results and enhance the functionality and flexibility of laser engraving machines to meet the requirements of various application scenarios. The cost of these additional accessories may increase, so specific needs and budget must be considered when evaluating the overall cost of a laser engraving machine.

- Rotary axis: Laser marking machines can engrave spherical, cylindrical, and other curved surfaces, such as cans, thermos cups, baseball bats, mugs, balls, vases, pen holders, and rings. By rotating the workpiece, continuous and smooth markings can be made on curved surfaces, suitable for circumferential marking of various circular or curved products.

- Dynamic focusing system: Allows the laser automatically focus can adjust during the marking process according to changes in the workpiece surface, suitable for marking uneven surfaces, ensuring clear and uniform marking effects on surfaces with different heights or curvatures. The surface irregularity is recommended not to exceed 5mm for adaptive engraving.

- CCD vision positioning system: Captures images of the workpiece through a camera, automatically locates the marking position after image processing, particularly suitable for high-precision positioning or marking of irregular workpieces in batches, significantly improving positioning accuracy.

- Two-dimensional worktable (XY table): Provides precise movement in the X and Y directions, expanding the marking area, making it possible to mark large-sized objects or perform multi-position marking. Through computer control, precise positioning and marking of complex patterns can be achieved.

- Conveyor belt interface: Used to integrate the laser marking machine into automated production lines, completing marking tasks while products flow continuously, greatly improving production efficiency, suitable for batch production and online marking needs.

- Automatic loading and unloading system: Automatically loads and unloads workpieces through mechanical arms or conveyors, reducing manual intervention and improving production efficiency, especially suitable for scenarios with large-scale and continuous production.

- Flying marking head (or online marking head): Designed for high-speed production lines, capable of marking while products are in motion, suitable for industries with high-speed continuous production such as packaging, wire and cable, and pipe manufacturing. The flying marking head can synchronize with the production line speed, ensuring marking quality without compromising production speed.

Which Laser Engraver is the Best for Curved Surfaces and Concave Convex Surface?

Laser marking machines are primarily used for flat processing because the laser focus of these machines is fixed. However, for regular curved surfaces such as cylinders, brake discs, metal rings, and other disc-shaped components, marking requirements can be achieved by rotating the axis while marking.

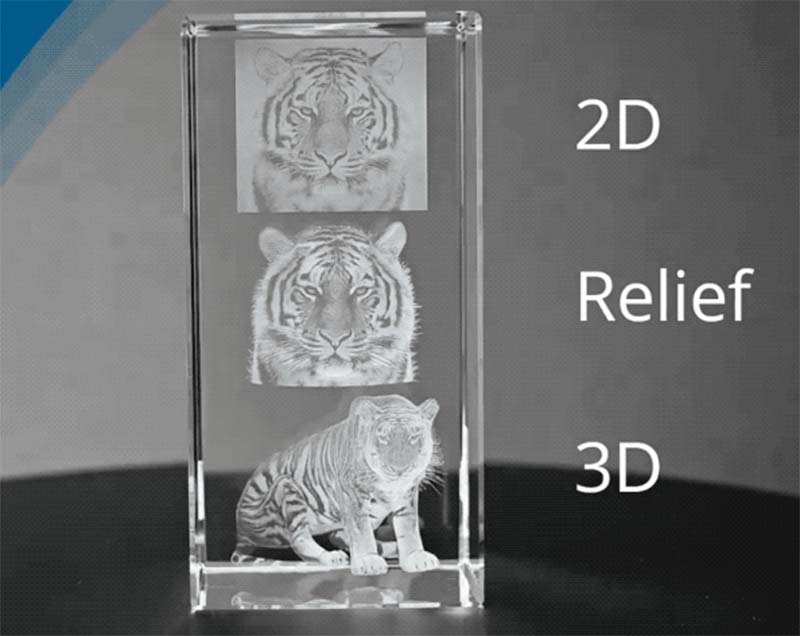

The emergence of 3D dynamic focusing laser marking machines meets the demands of marking applications on curved surfaces and variations in height in a single operation. These machines combine 3D dynamic galvanometer technology and software 3D modeling to achieve variable focus engraving, thus meeting laser marking and engraving requirements at different heights.

Features of 3D dynamic focusing laser engraving machines:

- Enable marking and engraving on curved surfaces and products with variations in height.

- High marking accuracy, fast marking speed, and one-time shaping.

- Improve production efficiency, achieve excellent marking effects, and further advance the application of laser marking.

What are the Applications of Laser Engraving Machine?

The versatility of laser engraving machines is truly remarkable, ranging from adding an elegant touch to personalized gifts to bringing precision to industrial applications. The following applications showcase the extensive possibilities of laser marking machine.

Industrial Manufacturing

Laser engraving technology plays an important role in modern manufacturing, penetrating into many branches of metalwork, plastic molding, mechanical parts, and electronic component refinement. With their ability to work with precision and efficiency, laser engraving machines significantly enhance the productivity of the manufacturing process and the quality of the finished product.

Precision Jewelry Engraving

Laser engraving machines play an indispensable role in the glittering arena of jewelry manufacturing. They are capable of creating subtle totems and characters on precious metals and stones, perfectly suited to the aesthetics of high-end jewelry and accessories.

Textile and Leather Cutting

The leather goods industry has witnessed the creative magic of laser engraving machines, which not only produce intricate and varied patterns and textures, but also give each piece of leather a unique style character, promoting the flourishing of personalized leather fashion.

Glass surface treatment

Laser technology has opened up a new world in the field of glass craftsmanship, through accurate engraving and etching technology, laser engraving machine is able to shape a vivid three-dimensional artistic effect on the glass plane, greatly enriching the expression and ornamental glass artwork.

Conclusion:

This article provides choosing the best laser engraving machine for beginners in 2024, emphasizing the importance of understanding actual engraving needs and applications. By understanding the different types of laser engraving machines and making the right choice for your specific needs, new possibilities open up for your personal project or business. In the meantime, we welcome discussion on the latest developments in laser engraving technology.