Laser cutting technology has transformed the manufacturing industry, offering precision and versatility across various materials. But can CO2 lasers effectively cut metal? In this article, we’ll explore CO2 laser cutter for metal, answering questions such as whether you can cut metal with a CO2 laser, the maximum thickness a CO2 laser cutting machine can handle, and the types of metals they are best suited for.

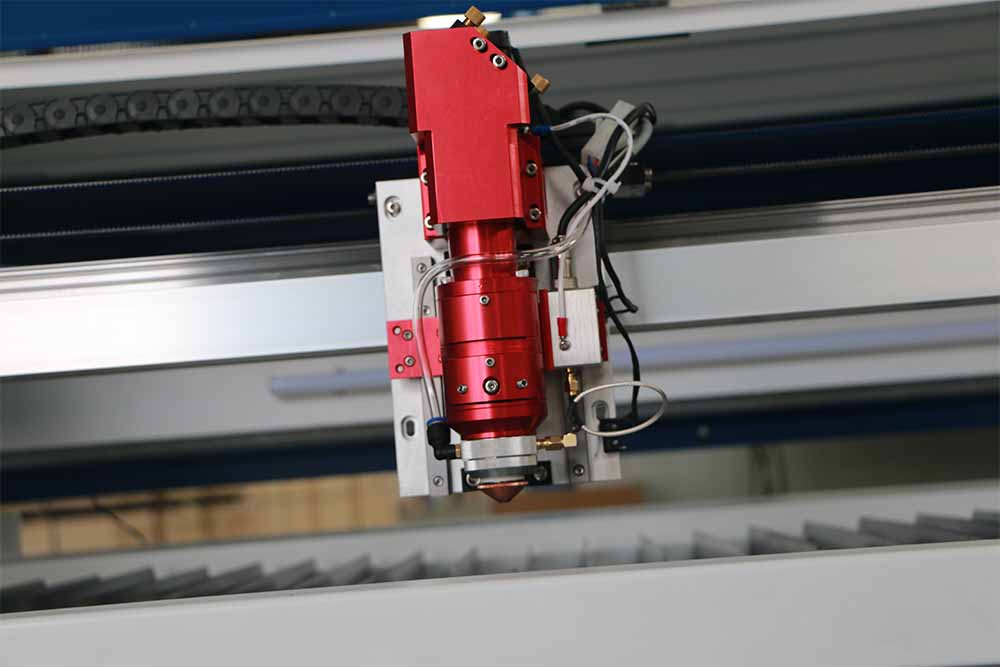

How Does CO2 Laser Cutting Machine Work?

CO2 laser cutting machines use a CO2 laser as the light source to generate laser light by filling a closed tube with a mixture of carbon dioxide, nitrogen and helium gases and exciting these gases with an electric current. The resulting laser beam is focused to create a high-temperature zone on the surface of the material, which locally melts or evaporates the material, resulting in precise cutting. By precisely controlling parameters such as laser intensity, focus size and travel path, different materials can be processed efficiently and finely.

Can CO2 Laser Cut Metal?

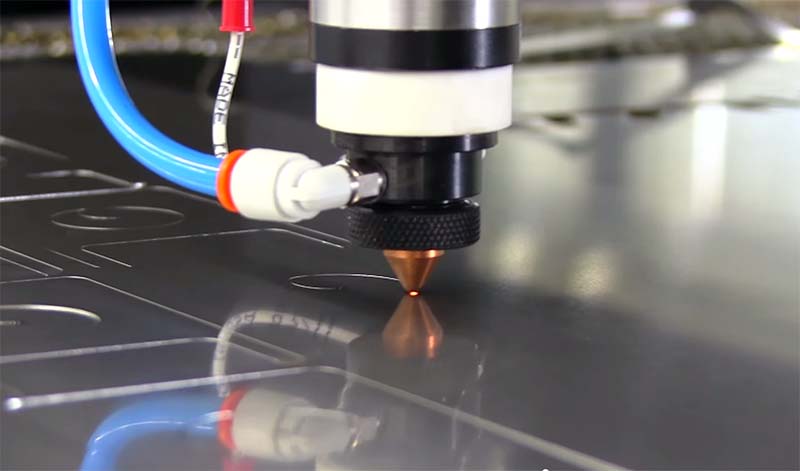

CO2 laser cutters can indeed be used for metal processing, but they are generally slower compared to other laser source. The high-powered laser beam rapidly heats the metal to extremely high temperatures, assisted by gases that help melt, vaporize, or remove the material. However, due to the longer wavelength of CO2 lasers, they are better suited for cutting thin metals and engraving on metal surfaces. When it comes to cutting thicker metals, CO2 lasers may struggle, as the laser has difficulty effectively penetrating thicker metal layers.

CO2 metal laser cutting machine come in a range of power levels. High-power CO2 lasers are ideal for cutting and engraving metal sheet materials, while lower-power versions are typically used for non-metal materials such as acrylic, wood, organic glass, marble, plastic, fabric, leather, and paper.

How Thick of Metal Can a Co2 Laser Cut?

CO2 laser cutters are primarily suitable for thin metal materials, with their maximum cutting thickness depending on factors such as laser power, material type, and desired cutting quality. Generally, CO2 laser machines exhibit the following capabilities:

Different Materials Cutting Capabilities

- For stainless steel, a CO2 laser cutter can effectively handle sheet metal with a thickness of up to 3 mm.

- For non-metallic materials, it can cut materials with a thickness of up to 20 mm.

While highly effective for precise cutting in specific applications, CO2 lasers are best suited for thinner metals and non-metal materials.

Different Power CO2 Laser Cutting Systems and Metal Cutting Thickness

The thickness of metal a CO2 laser cutter can effectively cut varies based on the machine’s power. For example:

A 300W CO2 laser cutter is suitable for cutting thin sheets, such as stainless steel or aluminum with a thickness of less than 1 mm.

A 600W~ 800W CO2 laser cutting machine can handle metal sheets with a thickness ranging from 2 mm~ 3 mm.

For thicker metal plates, a CO2 laser cutter may not be the most economical choice, as it can result in reduced cutting efficiency and quality. For metal cutting, we recommend using a fiber laser cutter, which offers better performance for thicker metals. CO2 laser cutters are more suitable for non-metal materials.

You should only consider using a CO2 laser cutter for metal if you’re processing needs include both metallic and non-metallic materials. After all, purchasing two different types of laser cutters is not ideal for your investment and output.

CO2 vs. Fiber Laser for Metal Cutting

| Laser Sources | Wavelength |

| CO2 laser | 10.6 micron |

| Fiber laser | 1.06 micron |

Fiber lasers have a shorter wavelength compared to CO2 lasers, making them more suitable for cutting metals. The shorter wavelength means that more of the laser beam’s energy is absorbed by the material, and less energy is reflected away. This leads to higher cutting efficiency, faster processing speeds, and better overall performance when working with metal materials. As a result, fiber laser cutting machines are often the preferred choice for cutting thicker metals or achieving high-quality cuts on reflective materials.

Which Metal Materials are not suitable for CO2 Laser Cutting?

CO2 laser cutting technology faces challenges when cutting & engraving some metals.

- Highly Reflective Metals: Metals such as gold, silver, and copper have high reflectivity. When a CO2 laser beam strikes these materials, most of the energy is reflected rather than absorbed. This not only reduces cutting efficiency but can also potentially damage the laser system due to the reflected energy.

- High Melting Point Metals: Metals like tungsten and molybdenum have extremely high melting points (for example, tungsten melts at around 3422°C). These metals require much higher temperatures for effective cutting, and standard CO2 laser systems typically cannot provide the necessary power to reach such temperatures, making CO2 laser cutting unsuitable for these materials.

- Thick Metal Plates: While CO2 lasers can cut various metal thicknesses, particularly thick metal plates (such as heavy stainless steel or carbon steel) require very high power density and longer processing times to complete the cut, reducing overall efficiency.

- Certain Special Alloys: Some special alloys may undergo unfavorable changes, such as cracking or structural damage, when exposed to high temperatures during the cutting process, making them unsuitable for CO2 laser cutting.

Can I Cut Aluminum with A CO2 Laser?

CO2 laser cutting machines face challenges when cutting aluminum plates due to aluminum’s high reflectivity and excellent thermal conductivity. These properties cause the laser beam to be reflected more easily and heat to dissipate quickly, making it difficult for CO2 lasers to cut aluminum effectively. In some cases, this can even damage the laser head.

To overcome these issues, assist gases are commonly used to improve the cutting process. Nitrogen is one of the most widely used assist gases, as it helps reduce reflection and prevents oxidation of the material. By using nitrogen, or a mixture of nitrogen and CO2, as an assist gas, aluminum can be cut more efficiently while maintaining cut quality and preventing oxidation. This method not only protects the laser equipment but also enhances cutting efficiency and precision.

Advantages of CO2 Laser Cutting Metal

High Precision: CO2 lasers can achieve cutting accuracy up to ±0.1 mm, making them ideal for intricate designs and tight tolerances.

Fast Cutting Speed: Suitable for high-volume production, significantly improving efficiency.

Excellent Cutting Quality: Produces smooth, high-precision edges that meet the requirements of most industries.

Wide Material Compatibility: Particularly effective for thin steel plates and supports a variety of materials.

Non-Contact Processing: Eliminates direct physical contact with the material, reducing the risk of surface damage.

Limitations of CO2 Laser Cutting Machines

High Initial Investment: The purchase of high-quality CO2 laser cutting equipment requires a significant upfront investment, making it less accessible for some businesses.

Limited Cutting Precision: While CO2 laser cutters provide good cutting quality, they may fall short when it comes to extremely fine work or applications requiring exceptionally high surface finish, as the cuts may appear slightly rough.

Limited Cutting Thickness: For industries dealing with thicker materials (such as heavy steel plates), CO2 laser cutters have limited penetration ability. As the material thickness increases, both efficiency and cutting quality tend to decline.

Maintenance Requirements: CO2 lasers have higher operating and maintenance costs. In addition to consumables and gases required to maintain optimal beam path transmission, energy costs can be up to 70% higher compared to other laser technologies.

What Can You Do With a CO2 Laser Cutting Machine?

The efficiency, high quality, precision, and non-polluting characteristics of CO2 laser cutting machines make them widely used in modern industrial production. Some key applications include:

- Metal Processing: CO2 lasers are suitable for cutting a variety of metals, such as low-carbon steel, stainless steel, aluminum, and more.

- Wood Processing: Widely used in furniture manufacturing, wood carving, and puzzle production, CO2 lasers can precisely cut complex shapes in wood.

- Plastic Processing: Ideal for cutting plastic sheets, pipes, films, and other plastic products, CO2 lasers ensure smooth edges without burrs.

- Textile Processing: Perfect for cutting fabrics, leather, and satin, CO2 lasers are especially useful in the garment industry for fabric cutting and shoe mold production.

- Polymer Materials: CO2 lasers are effective for cutting, engraving, perforating, and bending polymer materials like polyimide, polyurethane, polyester, polypropylene, polyethylene, and polypropylene.

- Other Non-Metal Materials: CO2 lasers are also used for precision cutting of non-metal materials such as ceramics, marble, glass, rubber, and more, meeting the special needs of various industries.

CNC CO2 laser cutting machines offer excellent performance in cutting, engraving, and marking non-metal materials, while also playing a significant role in thin metal manufacturing and engraving. These machines enhance production efficiency, reduce costs, and provide greater possibilities for innovative designs. Through high-precision processing, CO2 laser cutters not only improve product quality but also contribute to the modernization of industrial production.

In the metal processing industry, high-precision CO2 laser cutting technology demonstrates exceptional capability. It is particularly widely used in the electronics manufacturing sector, where it is applied for the precise cutting of electronic component housings, conductive materials, and circuit boards. The technology can accurately cut a variety of materials, including steel, stainless steel, and aluminum alloys, and is also ideal for cutting and engraving complex-shaped components.

Why Choose DPLASER as Your Metal Laser Cutting Machine Manufacturer?

Dapeng Laser’s fiber laser cutting machines and CO2 laser cutting systems position you as a leading manufacturer in the metal fabrication industry:

- Multiple Sizes and Power Options: A range of sizes and power levels to suit various cutting needs.

- Extensive Accessories and Automation Options: Equipped with a wide variety of accessories and automation features to enhance efficiency and flexibility.

- Higher Precision, Better Parts, and Faster Production: Offering improved precision, superior part quality, and faster production speeds for optimal results.

- Maximized Productivity and Profitability: Designed to maximize both productivity and profitability, ensuring cost-effective and high-performance cutting solutions.

With Dapeng Laser’s advanced systems, you can achieve cutting-edge results while staying ahead of industry demands.

To find the best laser cutting machine for metal, you should focus on high power, high speed, and high precision. The thickness of the metal being cut is also a key factor; for thicker materials, a more powerful fiber laser cutting machine is the better choice. Fiber lasers offer fast cutting speeds and high efficiency, and unlike CO2 lasers, they require less frequent maintenance. They can easily handle thicker materials and reflective metals such as aluminum, copper, and brass, providing cleaner cut edges and higher precision.

We offer high-quality CO2 metal laser cutting machine, designed for continuous operation around the clock to meet diverse design needs and handle complex structures. Whether it’s fine cutting, personalized engraving, or precision etching, our laser cutting solutions deliver exceptional precision and accuracy in processing a wide range of materials, ensuring that every project meets the highest standards.