UV Picosecond Laser Marking Machine

Ultrafast lasers, such as femtosecond or picosecond lasers, are highly effective in marking, drilling, and engraving due to their exceptional precision and minimal thermal impact. Compared to conventional lasers, they produce cleaner edges, finer details, and negligible heat-affected zones, making them suitable for delicate or high-value materials. They also allow for the processing of a broader range of materials, including brittle and transparent ones, with highest accuracy.

UV picosecond laser marking & engraving machines use laser beams to permanently mark or engrave various types of materials on their surfaces with superior precision and detail.

UV Pico-second Laser Machine for Marking Cutting & Drilling

The ultrafast laser marking machine has been widely used in glass cutting. By using an ultrafast laser with an extremely short pulse width (in the picosecond range), its high power density can focus on the glass surface to form very small light spots, creating stable light filaments within the glass, which makes the material brittle, thus enabling clean cutting.

For multilayer materials (such as glass with polyimide or PET coatings), femtosecond laser cutting machines perform even better. The high precision and short pulse characteristics of femtosecond lasers allow for the simultaneous cutting of different materials in the same process, meeting the market demand for composite material cutting, and improving both efficiency and cutting quality.

Features

- AMT UV picosecond lasers feature excellent optical quality, with beam quality (M² < 1.2) and customizable beam roundness exceeding 95%, along with reliable pulse stability (<2%) and power stability (<3%).

- The lasers offer power options of 5W, 15W, and 30W, with a wide frequency range from 100 kHz to 1600 kHz, customizable up to 10 MHz.

- At 1 MHz frequency, they can deliver over 30W of power, with single pulse energy exceeding 50 μJ. In burst mode, pulse energy is even higher, and single-pulse adjustments can be made to meet diverse application needs.

- The lasers support external trigger signal control, offering multiple trigger modes, including high/low level and rising/falling edge triggers, enabling on-demand pulse triggering (POD).

- AMT UV picosecond lasers are the ideal solution for precision tasks like OLED cutting and drilling, PI/FPC cutting, and mobile phone antenna cutting, thanks to their superior optical quality, exceptional stability, versatile trigger options, and flexible customization features.

|

Laser Source

|

Scanning Mirror

|

|

|

Lens λ=1064nm

|

Control Software

|

|

|

Computer Monitors

|

Laser Chiller

|

|

Advantages of UV Picosecond Laser Marking System

Stable Performance

- Homemade seed source (40000hrs lifespan)

- Proven solid-state amplifier technology

- Import of core components

Powerful

- All-in-one machine design

- Burst pulse editing function

- Support PSO function

- Data monitoring and analysis

- Power fast switching function

Low Maintenance Cost

- Modular design, can be maintained separately

- Quick after-sales response, on-site maintenance, low cost

Features:

- Superior beam quality (M2<1.2), support PSO, Burst, FFC mode, integrated design, compact structure, high long-term working stability.

- 24/7 industrial application, AMT-355 Series UV Picosecond Laser.

- Integrated design, simple structure, reliable performance.

- Narrow pulse width, high peak power, focus on micro-nano processing field.

- The operation is simple and user-friendly, and the equipment has good stability; the special control software is compatible with Auto CAD, CorelDRAW, Photoshop and other software output.

- Can receive various BMP, JPG, DXF, PLT, AI and other format files.

- Automatically generate various serial numbers, production dates, barcodes, and QR codes.

- Support flying marking and rotating marking.

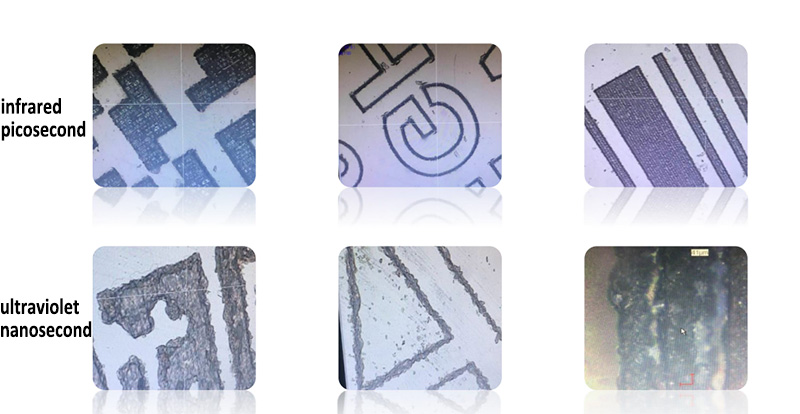

Marking Glass – comparison of infrared picosecond and ultraviolet nanosecond

Picosecond Laser Marking Application:

The picosecond laser can mark a wide range of materials, including metal, plastic, and glass, enabling it to be used for a variety of medical applications.

- Cutting and drilling of brittle materials, frosted glass surface (glass, sapphire and ceramics)

- LCD, OLED screen cutting

- Glassware marked scale – Home Appliance Industry

- Blackening of battery cell, anti-electrolyte corrosion – New Energy Industry

- Laser black marking on medical metal – Medical Equipment

- Acrylic inner carving – Decoration

- Jade deep carving, 3D relief carving – Crafts

- Marking of wafers – Semiconductor

- Aluminum oxide blackening – Metal Processing

- Ceramic dial scale for smart watch – Smart Wearable

- Picosecond laser marking for black aluminum oxide – Food Packaging

Widely used in integrated circuit chips, moulds, microelectronics, industrial bearings, clocks, aerospace devices, auto parts, wires and cables, medical equipment, and many other fields of graphics and text marking, mass production line operations.

|

|

|

OLED Laser Cutting |

Polarizer Laser Cutting |

|

|

|

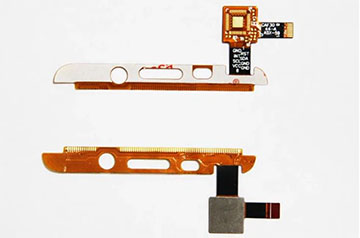

PI Laser Cutting |

FPC Laser Cutting |

Reviews

There are no reviews yet.