Laser cutting machines for tube are widely favored for their higher precision, faster cutting speeds, and excellent cutting quality. The high energy density of the laser beam allows for rapid cutting of tubes without causing any damage to the material itself. This characteristic makes laser tube cutting machines extensively used in fields such as tube processing, machinery manufacturing, petrochemicals, food processing, and fitness equipment.

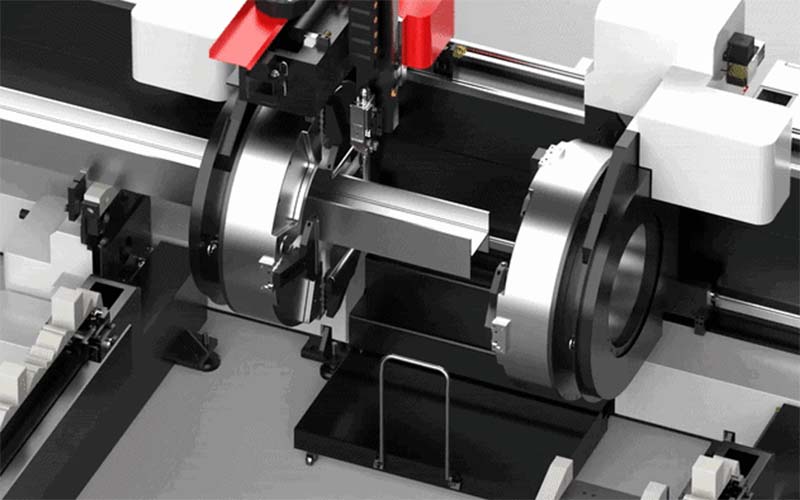

What is the chuck for laser tube cutting machine?During the cutting process, the pipe chuck for laser tube cutting machine plays a crucial role in both securing and rotating the tube. The chuck firmly grips tubes of various shapes and sizes through its clamping mechanism, ensuring that the material does not move during high-speed cutting, thus guaranteeing precision. Additionally, the chuck’s ability to rotate allows the laser head to perform omnidirectional cutting, making it particularly suitable for complex patterns or circular cuts. Furthermore, some laser tube cutting machines feature chucks with automatic adjustment systems that can adapt to the diameter and shape of the tubes, further enhancing operational efficiency and cutting accuracy.

How to choose the chuck when purchasing a laser tube cutting machine? First, we need to consider the diameter and length of the tubes. For larger diameter and longer tubes, a single chuck may not provide sufficient holding force, leading to movement during the cutting process. In such cases, increasing the number of chucks can enhance the stability of the tube and improve cutting accuracy.

Laser Pipe Cutter Chuck Parameters

Chuck Size

The size of a laser tube cutting machine chuck usually refers to its diameter, with common ranges between 80mm~630mm, though larger or smaller chucks can be used for specific processing needs. The selection of chuck size should be based on the diameter, length of the tubes, processing requirements, and the laser cutter’s capacity.

Number of Chuck

Common chucks have three, four, or six jaws, with three- chuck and four-chuck being the most prevalent. Three-jaw chucks are used for round workpieces, while four-jaw chucks are suitable for irregular or non-circular workpieces.

Three-Chuck

A three-chuck consists of front, middle, and rear jaws, all of which move simultaneously and adjust as needed to hold round workpieces. Due to its simple structure and ease of operation, it is often used for rough machining where high precision is not required, quickly improving processing efficiency. However, it has limitations regarding the length of the final tube section, making zero-tail material cutting difficult.

This type of pipe laser cutting machine is suitable for square, rectangular, and round tubes, efficiently handling these common shapes. While it can process other irregular tubes, its precision is not as high as that of a four-jaw chuck.

Four-Chuck

The four-chuck independent chuck allows each jaw to move and position independently, making it ideal for securing workpieces of various shapes and sizes, especially non-circular or irregularly shaped ones. It is suited for high-precision machining environments, such as fine turning and grinding, ensuring accurate positioning of the workpiece to maintain cutting quality.

The four jaws can clamp and cut simultaneously, and during the final stage of cutting, the material is pulled back for truly zero-tail material cutting.

The four-chuck excels when processing irregular-shaped tubes (such as oval or custom profiles). Its design offers greater versatility and control, ensuring high-precision cutting of complex shapes.

3-Jaw vs. 4-Jaw Laser Cutter Chuck

3-jaw chucks are suitable for less precise machining, especially for clamping small, regular-shaped workpieces. In contrast, 4-jaw chucks are more robust, better handling heavier and irregular-shaped workpieces, making them ideal for high-precision machining of larger workpieces.

In practice, the choice of chuck should be based on the workpiece’s shape, size, and precision requirements. Both three-jaw and four-jaw laser tube cutting machines are designed to cut various materials, such as carbon steel, stainless steel, aluminum, copper, and other metal and non-metal materials.

Power Types

Available power types include manual, pneumatic, hydraulic, and electric chucks.

Maximum Clamping Range

The maximum clamping range refers to the range of workpiece diameters that the chuck can hold when opened or closed. The appropriate specification should be chosen based on the diameter of the workpieces.

Through-Hole Diameter

The through-hole diameter refers to the central hole in the chuck, allowing long workpieces to pass through, making it suitable for processing long tubular or shaft-like workpieces.

Chuck Spacing

Chuck spacing should be selected based on the length of the tubes being cut. The longer the tube, the larger the chuck spacing required.

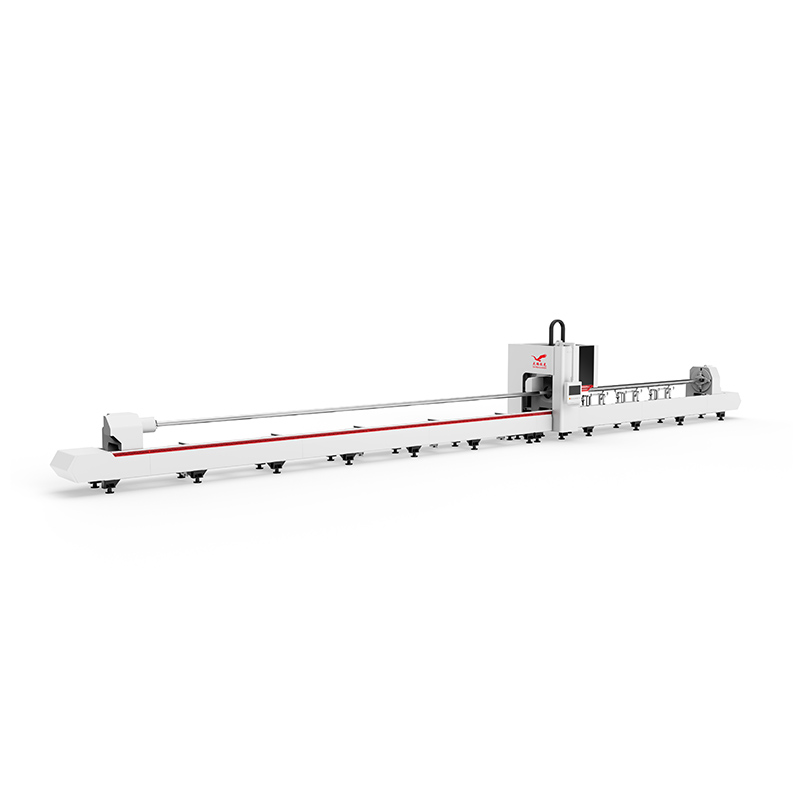

Horizontal Tube Laser Cutting Machine

The horizontal laser tube cutting machine features a design where the workpiece is placed horizontally, and the tubes are transported horizontally into the processing area through a conveyor system.

Features:

- Wide Application Range: Capable of processing various shapes of tubes, such as round, square, and rectangular, making it suitable for most industrial applications.

- High Stability: The horizontal placement of the workpiece ensures even force distribution during processing, providing high precision and stability.

- Suitable for Large Diameter Tubes: The horizontal structure can handle large-diameter and longer tubes, commonly used in industries such as construction, machinery manufacturing, and metal furniture.

- Convenient Operation: With horizontal placement, loading and unloading of workpieces are more convenient, making it ideal for mass production and continuous processing.

- Larger Footprint: The machine’s size typically requires a larger installation space, needing enough room for operation.

Side-Mounted Laser Tube Cutting Machine

The side hanging laser tube cutting machine adopts a design where the workpiece is suspended beside the machine for processing.

Features:

- High Flexibility: The tube is suspended in the machine’s clamping device, making the hanging tube cutting machine more flexible and ideal for processing irregular and custom-shaped tubes.

- Space-Efficient: The hanging design is more compact, making it especially suitable for small workshops or production lines that require space-saving solutions.

- Precise Clamping: Hanging laser tube cutting machines are often equipped with advanced clamping devices, ensuring high-precision positioning during the cutting process, reducing errors.

- Suitable for Lightweight Tubes: The hanging design is more suitable for processing medium-sized, lightweight tubes and is not ideal for handling very heavy or large-diameter tubes.

- High Automation Level: Hanging tube cutting machines usually integrate automatic loading and unloading systems, making them suitable for automated production lines and enhancing production efficiency.

For tubes with lengths of 6000mm or more, sagging and shaking during cutting can affect precision. Three-chuck laser tube cutting machine and four-chuck fiber laser cutting machine for tube effectively solve these issues, reducing pipe waste and improving cutting accuracy. Additionally, these laser pipe cutters are compatible with both automated and semi-automated loading and unloading systems, offering more options for production line automation and further enhancing production efficiency.

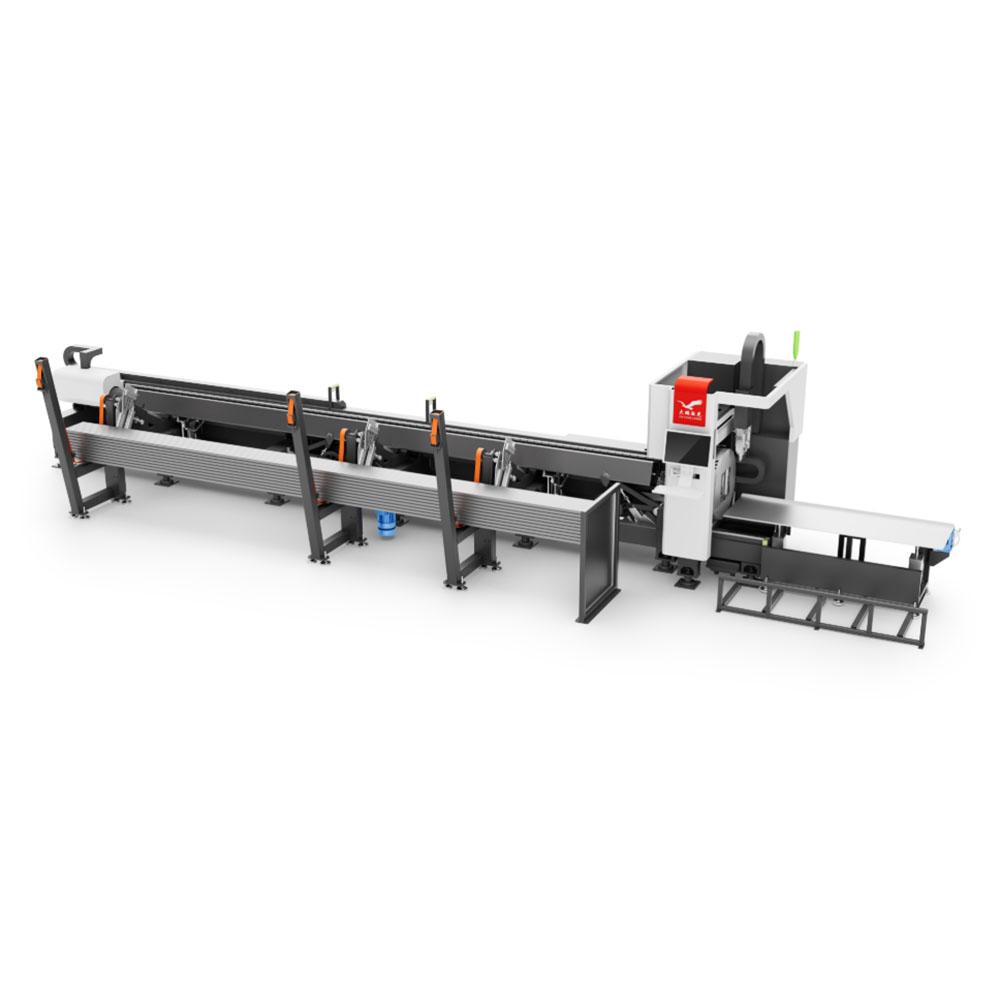

Three-chuck Fiber Laser Tube Cutting Machine

The zero tailing three-chucks tube laser cutter, designed for large-diameter heavy tubes, offers high load capacity and cost-efficiency. It is widely used in industries such as metal processing, construction materials, pipelines, steel structures, elevator manufacturing, fitness equipment, and machinery manufacturing.

- The machine features three chucks: two pneumatic chucks at the front and rear, and one electric chuck in the middle. These three chucks can simultaneously clamp the tube during cutting, preventing tube wobbling and enhancing cutting precision.

- The machine enables zero-scrap cutting, minimizing waste generation and reducing processing costs.

- The chucks are equipped with an automatic adjustment function, allowing them to adapt to various tube sizes, ensuring quick centering and clamping, which reduces deformation during cutting and improves overall precision.

Features:

Three-chuck Clamping System

The three chucks laser tube cutting machine uses three independent chucks to clamp the tube, equipped with an independent floating support system. This support system adjusts based on the length and shape of the tube, ensuring stability and accuracy during cutting.

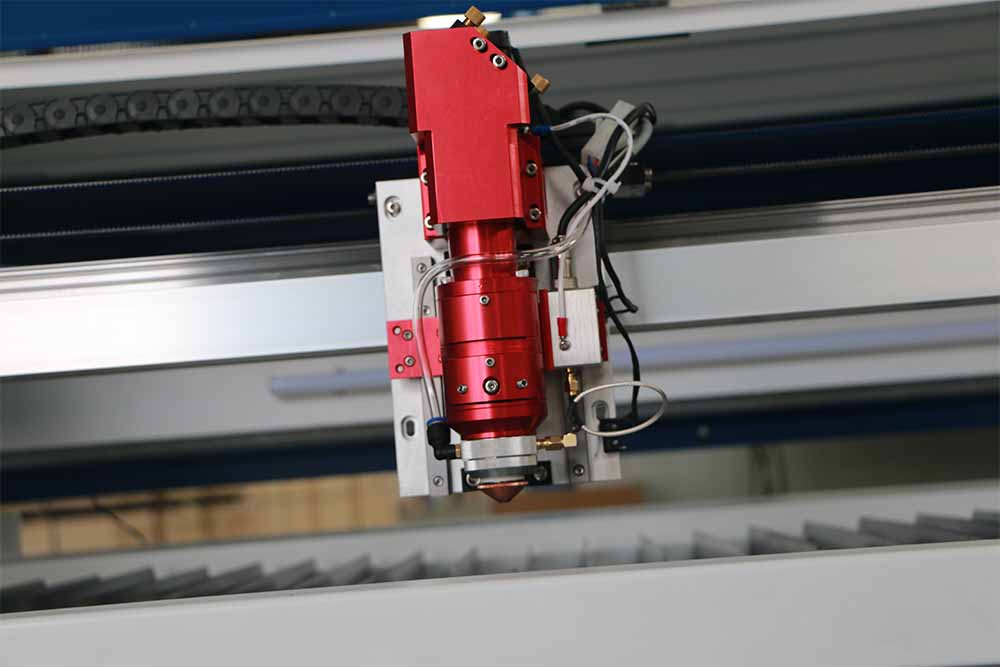

Laser Cutting Technology

The three chucks laser tube cutting machine for pipe utilizes a high-energy laser beam to melt and cut the tube. After focusing, the laser beam’s energy is highly concentrated, allowing it to quickly melt the tube and create precise cuts.

CNC System

Equipped with an advanced CNC system, the three-chuck zero-scrap laser tube cutting machine precisely controls cutting paths, speeds, and power parameters, while also providing real-time monitoring to ensure cutting quality.

Automatic Feeding System

This machine typically comes with an automatic feeding system, allowing for automated loading, feeding, and unloading of tubes, significantly boosting production efficiency and reducing labor costs.

Zero Tailing Cutting

By adjusting the position of the chucks, the three-chuck laser tube cutting machine achieves zero-scrap cutting, maximizing material utilization and lowering production costs.

Versatile Tube Processing

With a low center of gravity and stable side-hanging bed design, the three-chuck system can handle large-diameter tubes and is suitable for processing round tubes, square tubes, rectangular tubes, oval tubes, bevel tubes, I-beams, channel steel, and more.

High-precision Cutting

The heavy duty tube laser cutting machine employs advanced laser cutting technology, combined with precise control systems and optimized cutting parameters, to deliver high-precision cuts that meet stringent industrial and manufacturing quality standards.

Should You Invest in a Three-Chuck or Four-Chuck Pipe Fiber Laser Cutting Machine?

In this blog post, we thoroughly explore the conditions under which both three-chuck and four-chuck laser tube cutting systems are best suited. By understanding their applications, advantages, and limitations, you’ll be able to make the smartest choice for your business needs.

Finally:

We’ve provided a comprehensive comparison of chuck for laser tube cutting machine. The price of tube laser cutting machines can vary significantly based on factors such as power, applicable materials, model, size, and additional features. For example, machines with more chucks, bevel cutting heads, or automatic feeding systems tend to have a higher cost. To make an informed decision, we recommend evaluating your specific processing needs and comparing different models. Feel free to contact us for detailed pricing information, and we’ll provide an accurate quote tailored to your requirements and specifications.