Conventional laser engraving machines were traditionally confined to precise marking operations on two-dimensional flat surfaces. However, the 3D laser engraving technology has transcended this limitation, enabling labeling on components with intricate curved surfaces and depth variations. Such 3d fiber laser marking machine integrate 3D dynamic galvanometer hardware with robust three-dimensional modeling software, allowing for real-time adjustment and pinpoint focusing of the engraving focal point. This zoom capability endows the equipment with the versatility to perform flexible, efficient, and high-quality laser marking and engraving on surfaces of varying heights and curvatures, significantly broadening the application scope of laser engraving to the contemporary market’s demand.

What Is 3d Laser Engraving?

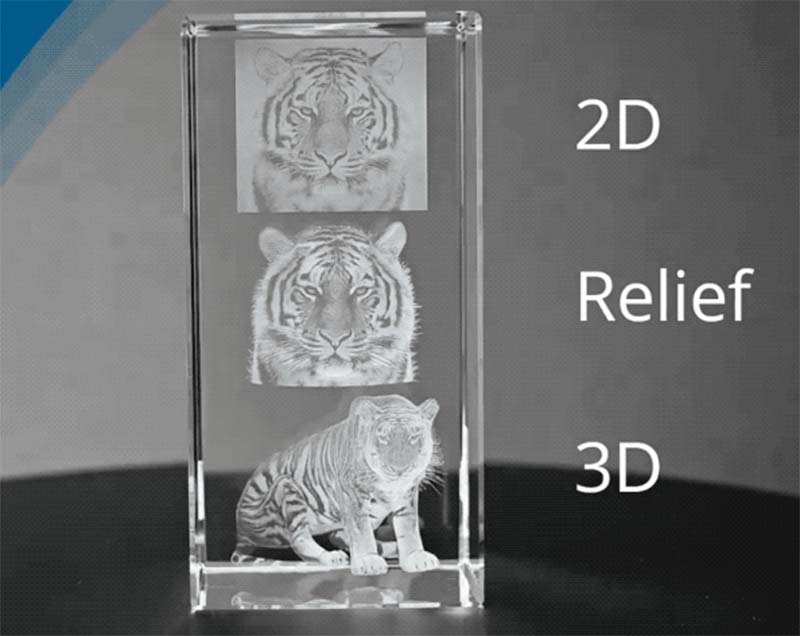

3D laser engraving is a technique used to etch or engrave intricate designs, patterns, or images onto a three-dimensional surface using a laser beam. Unlike traditional engraving methods, which may be limited to flat surfaces, 3D laser engraving can create different depths, hollowing, etching, embossing, relief and on various materials such as wood, metal, glass, and acrylic. It involves directing a high-powered laser beam onto the material, which vaporizes or removes layers to create the desired three-dimensional effect.

How to Laser Engrave on Curved Surfaces?

Laser engraving curved surface typically requires the assistance of auxiliary tools, such as rotary fixtures, to handle cylindrical objects like tubes, bottles, kettle, light bulb etc. For irregular and uneven surfaces, a laser head with automatic focus adjustment capability can be selected for processing. Laser engraving machine manufacturers are able to produce automatic focus laser heads suitable for both metal and non-metal materials, thus enabling engraving on curved surfaces.

Auxiliary accessories can enhance the engraving capabilities and effects of laser engraving machines on curved surfaces:

- Rotary axis: A rotary axis is an attachment that allows the workpiece to rotate on the laser engraving machine, enabling the laser to engrave along curved surfaces.

- Automatic focus adjustment system: An automatic focus system can automatically adjust the focus on curved surfaces, ensuring that the laser beam maintains focus on surfaces with different curvatures, thus achieving better engraving effects.

- 3D scanner: For complex curved surfaces, it may be necessary to first use a 3D scanner to scan the workpiece to obtain geometric information about the surface and convert it into a format recognizable and engraveable by the laser engraving machine.

- Fixtures or securing devices: For some shapes with complex curved surfaces, special fixtures or securing devices may be needed to stabilize the workpiece during the engraving process.

- Specialized software: Choosing appropriate software to generate or edit engraving models ensures that the models can adapt to curved surfaces and generate suitable tool paths.

What are the Advantages of 3d Laser Marking Machine?

3D laser engraving is the use of high energy density laser beam action on the target, the use of high-energy, short pulse laser, so that the material instantaneous vaporization, without harming the surrounding material, and can accurately control the depth of the action, so that the target surface physical or chemical changes, which replaces the traditional chisel and carving knife, the excess of the workpiece to remove the engraving, so as to obtain the visible pattern of the engraving method.

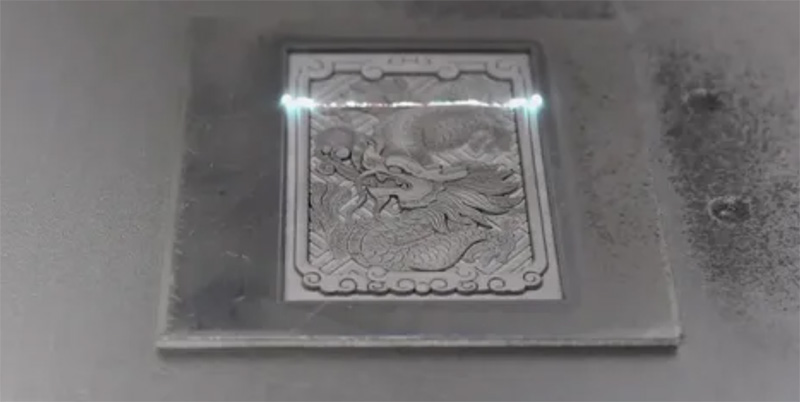

3D laser marking is mainly applied to aluminum, zinc, copper, nickel, steel and other metal materials and stainless steel metal appearance to achieve three-dimensional concave and convex engraving and plane fine-grained engraving, imaging level smooth, to achieve a truly 3-dimensional high quality. Large depth of textured metal plate, can be directly on the metal material to achieve a variety of patterns and colors.

1. High Precision and Stability

3D laser marking machines are equipped with precision control systems and high-quality optical components, ensuring high-precision positioning and stable output power during rapid marking processes. Whether it’s linear motion or movement along complex curved trajectories, it can accurately track and quickly complete marking tasks, meeting the rapid prototyping needs for complex graphics, deep engraving, or fine textures.

2. High Speed and Efficiency

Laser marking itself has the characteristic of rapid response. Combined with the high-speed scanning mirrors and efficient laser sources of 3D laser marking machines, they can complete large-area, multi-level three-dimensional marking tasks in a short time. Rapid data processing capability and efficient laser energy conversion make the entire marking process extremely swift, greatly reducing the production cycle.

3. Wide Application Range

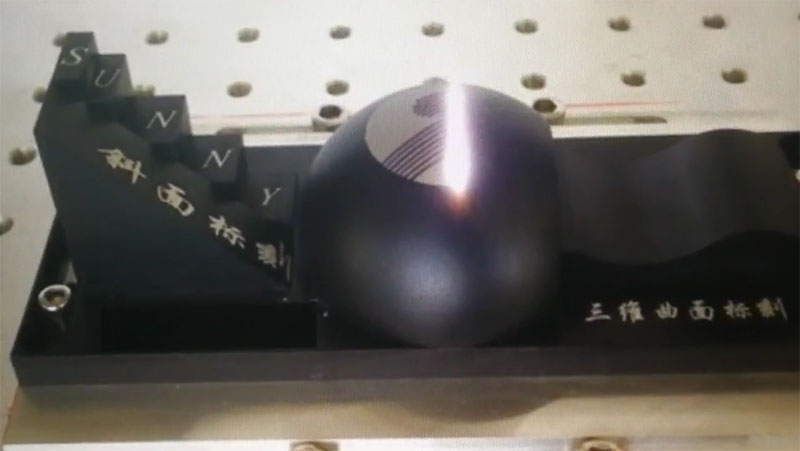

3D laser markers feature 3D surface engraving capabilities, allowing for precise, uniform marking within a tolerance height range of 0-60mm without requiring refocusing. They can mark irregular products, such as curved, slanted, stepped, spherical, cylindrical, and conical surfaces in a single pass.

4. Finer Spot Size

The 3D laser engravers utilize a front-focusing optical mode with large X- and Y-axis deflector mirrors with high-precision control to enable smaller laser spot sizes. This design ensures superior focusing accuracy and concentrates the laser energy on the surface of the workpiece, resulting in improved marking fineness and depth control.

5. Deep Relief & Embossing

Equipped with a 3D laser engraving system, these machines cater to various needs like embossing, deep engraving, and relief carving, delivering high precision and visually appealing results. They consistently mark parts with height differences, even on slopes, preventing distortion or color variance.

6. Color Engraving

Color engraving involves creating black, white, or multicolored marks on a single plane, offering versatile effects. For blackening metals (e.g., anodized aluminum), high-frequency pulses at appropriate energies are used, with focal distance adjustments significantly influencing energy distribution and color outcomes. Even for 2D users without advanced needs, 3D portable fiber laser markers can achieve multi-gray-scale, multicolor marking.

7. Large Processing Area

Combining a spacious worktable with a large-travel dynamic focusing system, these devices can cover extensive areas of a workpiece in one marking job. With processing areas ranging from tens of centimeters to several meters, they accommodate diverse industrial demands, handling both large-part marking and batch processing of small, complex curved parts while maintaining consistent quality.

3D laser engraver machines incorporate advanced 3D scanning galvanometers and control systems with multi-axis dynamic focusing technology, tracking deep-curve foci in real time. They support versatile applications, including surface engraving, deep engraving, and large-format marking.

3D Laser Cutting and Engraving Application

3D laser marking is an advanced non-contact processing method, capable of all kinds of materials complex surfaces engraving, fine and three-dimensional identification code, LOGO, patterns, text and other markings.

Precision instrumentation parts, precision gauges of key information through three-dimensional marking to ensure that the mark is clear and permanent and not easy to wear.

Electrical appliances and electronic components

3D laser engraving machine can be used for line marking of PCB boards, as well as 3C electronic product shells, internal components of personalized design and anti-counterfeiting traceability code production, which all need high precision and depth controllable marking effect.

Jewelry industry

The use of 3D laser marking can be in a variety of curved surfaces and planar metal materials to achieve artistic relief effect, enhance the processing accuracy of the product, the appearance of texture and brand recognition.

Mold manufacturing

Complex three-dimensional structure can be laser marking for fine processing, such as injection mold cavity wall engraving or die-casting mold key parts of the marking.

Stainless steel kettle, ceramic cups, rice cooker liners

The use of three-dimensional laser marking can be realized in the irregular curved surface or depth of the groove customized three-dimensional graphic engraving, enhance the added value of the product and user experience.

Packaging industry

For all kinds of packaging boxes, bottle caps, labels, etc., the use of three-dimensional laser marking can produce visually striking three-dimensional logo and graphics, which helps to improve the brand image and product grade.

Decorations & buildings

3d laser carving is also applicable to building decoration materials, such as glass, ceramic tiles, stone, etc., can be created on the surface of the delicate and rich three-dimensional pattern, so that the building inside and outside the space of a more artistic sense of aesthetics.

Precision micro-processing

3D laser marking can be used in microelectronics, biochips, optical components and other fields of micro-structure processing, to achieve fine engraving at the nanometer level.

3D Laser Engraving Marking Machine

3D laser engraving metal is specialized in marking on three-dimensional curved surfaces of metal. It utilizes a laser to output high-energy laser and realizes accurate marking through a high-speed scanning galvanometer system. Adopting fiber laser technology, it has high efficiency of electro-optical conversion, and adopts air-cooling method for heat dissipation, which makes the whole machine compact, and at the same time ensures the quality of the output beam and the reliability of the system. In addition, the system can be equipped with optional CO2 and UV lasers, which can be used for engraving non-metallic materials and has a wide range of application potential.

In curved surfaces and complex surface, the 3D laser engraving machine can easily accomplish marking tasks:

1. The 3D laser marker can accurately achieve laser marking on curved workpieces without defocusing during processing. It can handle deep engraving on complex surfaces such as ring-shaped, spherical, and curved surfaces with ease. By rapidly adjusting the laser focal length and position, the laser beam is scanned onto the product surface, leaving behind engraved traces along the scanned path.

2. Features include long laser lifespan, high precision of ±0.02mm, high stability for 24-hour continuous production, high laser conversion efficiency, and no consumables required.

3. With high-speed focusing and scanning systems, precise three-dimensional positioning technology involving laser beam mode, short pulses, high peak power, and high repetition frequency can deliver satisfying marking results.

4. Capable of fine marking, one-pass forming, fast speed, omnidirectional movement, and starting engraving from any point, ensuring clear and permanent engraving.

5. Can engrave fragile and brittle materials as well as extremely soft and hard materials.

6. Easily controlled by numerical control or computer automation, and can be operated at multiple workstations.

Applicable industries include:

1. LED lights, lamp holders, flashlights, water cups, etc.

2. Common metals and alloys (especially suitable for aluminum alloys), surfaces with special treatments (phosphating, aluminum anodizing, electroplated surfaces), plastics, PVC/PC/PUABS materials, epoxy resins, etc.

What Kind of 3d Laser Engraver Do You Need?

As a professional provider of laser engraving solutions, we tailor the most suitable laser engraving machine to your specific needs. Our product range covers laser marking, engraving, and cutting equipment, from two-dimensional flat surfaces to three-dimensional multi-angle shapes. Whether it’s marking on precision mechanical components, creating intricate patterns for crafts and hardware, or processing various materials like plastics, ceramics, metals, and acrylics.

For customers requiring high-quality marking on irregular-shaped products such as different curved surfaces, slopes, steps, spheres, cylinders, cones, etc., our 3D laser engraving machine is the ideal choice. Equipped with automatic focal length adjustment, it flexibly focuses within a tolerance height range of 0 to 60mm, ensuring fast and uniform marking effects. Whether it’s relief, deep engraving, or embossed carving, it achieves high precision and aesthetics.

Considering diverse processing needs across industries, our equipment offers a variety of processing area specifications, covering small precision parts to large sheets, ensuring efficient and stable production capacity.

Just provide us with your specific application scenarios, material, processing requirements, expected engraving precision and speed, as well as details regarding workpiece sizes and shapes, and we’ll recommend the most suitable product and provide personalized customization services. This ensures maximizing your production efficiency and helps enhance the quality and competitiveness of your products in the market.

In conclusion, 3D laser engraving curved surface widespread attention for its unique charm and versatility across industries, from manufacturing to the arts, revolutionizing processes and enabling intricate, rapid multidimensional designs on various materials, including complex curved surfaces. As this technology continues to evolve, it promises further groundbreaking applications and efficiencies, solidifying its status as a pivotal force in the realms of precision engineering and artistic expression.