This article will introduce you to an exceptional three-in-one laser welding, cleaning, and cutting machine that integrates welding, cleaning, and cutting functions into one. This innovative technology is generating widespread attention in the industrial sector, as it combines multiple laser technology into one system, offering unprecedented convenience to manufacturing and maintenance fields. In this article, we will delve into the key features of 3 in 1 handheld laser welder cleaner cutter and its practical applications in various domains such as metal manufacturing, automated production lines, maintenance, and repair. You will gain insights into how to apply it to different work scenarios to achieve higher efficiency and quality.

What is 3 in 1 Handheld Laser Welding?

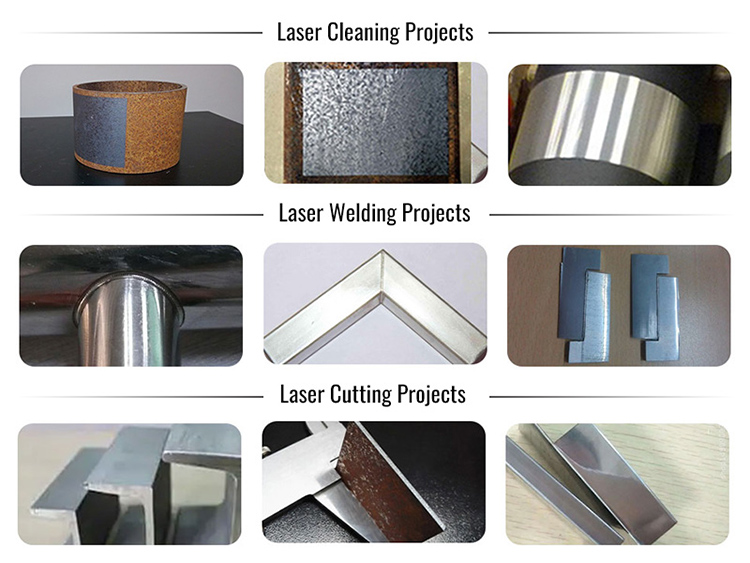

The laser welding, cutting, and cleaning 3 in 1 machine is a multifunctional device that combines laser technology for welding, cutting, and cleaning operations on metal materials. It utilizes high-energy laser beams to process workpieces, offering advantages such as high precision, fast speed, and high efficiency.

Welding: In terms of laser welding, this machine can be used to weld metal parts of different materials, such as carbon steel, stainless steel, aluminum alloys, and more. Laser welding features a small heat-affected zone and high weld quality, enabling high-strength welding connections.

Cutting: For cutting, the machine focus the laser beam onto a tiny spot to achieve cutting by melting or vaporizing the material. It is suitable for cutting various metal materials like stainless steel, copper, etc. Laser cutting offers benefits like no contact, no burrs, and clean edges, achieving high-precision cutting results, even for stainless steel plates below 6mm.

Cleaning: Additionally, the 3 in one laser welding machine can also be employed for cleaning the surface of workpieces. By adjusting the parameters of the laser beam, it can remove dirt, oxide layers, and other contaminants from the workpiece’s surface, restoring its original appearance of the material.

A laser equipment that combines the triple functions of laser welding, cleaning, and cutting in one machine. It can swiftly and easily remove oil, rust, and coatings before welding, and clean debris and discoloration after welding. It also performs various sheet metal cutting processes for quick repair. This equipment is designed to efficiently assist customers in achieving optimal work efficiency and meets the requirements of a wide range of work scenarios.

In addition, the 5 in 1 handheld laser welding machine refers to the machine’s capability to perform different welding functions, which may include spot welding, seam welding, pulse welding, continuous welding, and refill welding. The handheld design enables easy operation in various welding applications. This type of machine is often used for repairing or joining metal parts.

The Best 3-in-1handheld Laser Welding Machine

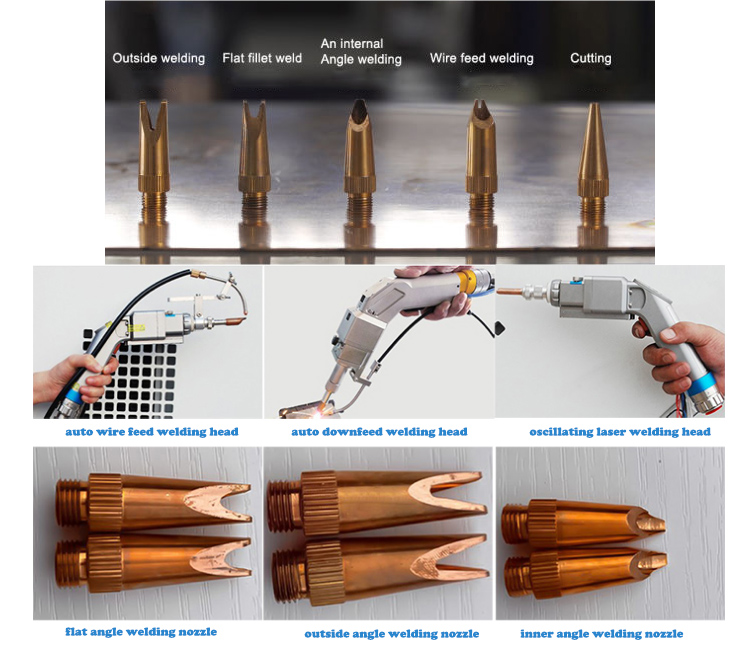

DPLASER 3-in-1handheld laser welding machine adopts imported continuous fiber laser source, equipped with a three-in-one (rust removal, cutting, welding) handheld gun head and control system, along with automatic wire feeding. It features advantages such as easy operation, user-friendly interface, aesthetically pleasing weld seams, fast welding speed, and no consumables. The machine is equipped with a dedicated cutting copper nozzle, which can cut metal sheets easily by increasing the air pressure. It can achieve rust and oxide layer removal on sheet metal, with adjustable scanning width of up to 50mm.

3 In 1 Handheld Laser Welding Features

* Compact in size and multifunction, the machine allows easy switching between its three major functions: cutting, welding, and rust removal. Users can conveniently set parameters through the touch screen.

* Equipped with a water cooling system and various types of welding nozzles including welding copper nozzle, wire feeding nozzle, V-type nozzle, and positioning nozzle. It also includes components such as a dedicated cutting nozzle for cutting function.

* The specialized cutting nozzle is designed for cutting, resulting in small cutting gaps and no burrs.

* Capable of rust removal and oxide layer removal on various metal sheets.

* The small-sized cabinet with dimensions of 950*750*1030 occupies less space, offering flexibility and convenience.

* It supports continuous welding with an automatic wire feeding machine, resulting in aesthetically pleasing and high-quality weld spots. Single-sided welding can achieve double-sided forming for stronger welds.

* The welding speed is fast, being 2-3 times faster than traditional welding, and the operation is straightforward.

* It excels in welding thin stainless steel, aluminum alloy, iron sheet, galvanized sheet, and other metal materials, making it a perfect replacement for traditional processes like TIG and MIG welding. Compared to TIG and MIG welding, this product boosts welding speed by 4 times.

* Equipped with a 10 meters optical fiber cable suitable for welding arc seams, straight seams, slopes, inner angles, outer angles, and any angle.

Components

The handheld laser head features a sleek appearance, small size, and lightweight design, allowing for prolonged handheld use. The integrated design of buttons and handle makes it user-friendly and easy to use. Depending on different usage scenarios, the three functions of welding, cleaning, and cutting can be easily switched through the smart controller.

The fiber laser generator can be chosen from BWT, Raycus, MAX, and other options, offering higher photoelectric conversion efficiency, lower error rate, low power consumption, maintenance-free operation, and a compact structure.

The built-in Hanli water chiller adapts to various environments, providing excellent dust and condensation protection. An industrial water cooling system ensures efficient heat dissipation for the core optical components, maintaining consistent welding quality and enhancing welding performance.

The automatic wire feeder can adjust wire feeding speed via the touchscreen. It offers high precision in wire feeding repetition, eliminating the instability and low efficiency associated with manual wire feeding.

The standard package includes 6 copper nozzles, 5 protective lenses, a pair of safety glasses, 1 data connection cable, and a 3-meter air hose.

Welding Parameters of 3 in 1 Handheld Fiber Laser Welding

| Material | Gas used | Thickness(mm) | Laser power(W) | Wire diameter(mm) | Wire speed(mm/s) | Scanning speed(mm/s) | Scan width(mm) | Welding frequency(HZ) | Duty cycle | Barometric pressure(bar) | Welding method |

| Stainless steel | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 1500 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 2000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 4 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| Carbon steel | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 1500 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.2 | 75 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 2000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 4 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| Galvanized sheet | Argon | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1500 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 2000 | 1.2 | 75 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.6 | 60 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding | ||

| Aluminum | Nitrogen(N2) | 1 | 1000 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding |

| 1.5 | 1500 | 1 | 90 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2 | 2000 | 1.2 | 75 | 300 | 2.5 | 1000Hz | 100 | 10 | Flat welding | ||

| 2.5 | 2000 | 1.6 | 60 | 300 | 3 | 1000Hz | 100 | 10 | Flat welding | ||

| 3 | 3000 | 1.6 | 60 | 300 | 3.5 | 1000Hz | 100 | 10 | Flat welding |

Applications of Handheld Laser Welding Cutting and Cleaning Systems

Suitable for various metal materials such as aluminum alloy, carbon steel, refined copper, dissimilar metals, and high-reflective materials, both thick and thin; fulfilling needs for flat welding, inner angle welding, outer angle welding, cutting, weld bead cleaning, rust and paint layer removal, and more.

Application Industry

The 3-in-1handheld laser welding machine is applicable to the welding, cleaning, and cutting processing of multiple metals, including stainless steel, carbon steel, copper, aluminum, galvanized sheet, etc. It finds extensive application in industries such as kitchen cabinets, staircases, elevators, shelves, ovens, stainless steel doors, window railings, distribution boxes, medical equipment, communication devices, battery manufacturing, decorative crafts, home furnishings, and more.

Metal Manufacturing:

In the field of metal manufacturing, this three-in-one laser welding, cutting, rust removal machine can achieve high-precision metal joining and repair. Its laser welding function can be used to connect different types and thicknesses of metals, thereby enhancing the strength and reliability of products in the manufacturing process. At the same time, its cutting function enables precise cutting on metal sheets, used for customized parts and components.

Door and Window Frame Welding:

In the door and window frame manufacturing industry, this equipment can achieve precise welding, ensuring the stability and sealing of door and window frames. Its laser welding technology can quickly connect door and window frames and repair leaks in the water sink without damaging the metal material. This reduces the heat-affected zone created during welding, thus improving product quality.

Vehicle and Marine Maintenance

In the field of vehicle and ship maintenance, the cleaning function of this equipment is particularly important. Its laser cleaning technology can effectively remove dirt, oxides, and coatings from the metal surface, creating a clean foundation for maintenance and painting. The welding and cutting functions can be used for repairing and replacing metal components of vehicles and ships, enabling fast and accurate repairs.

How to Use 3 in 1 Laser Welding Cleaning Cutting Machine

Startup Preparation:

Safety Precautions: Ensure you are wearing appropriate personal protective equipment such as safety glasses, gloves, and suitable work attire. Make sure your working environment is well-ventilated to prevent the accumulation of smoke and gases.

Workspace Setup: Clear your workbench and ensure there are no flammable materials or clutter around. Place the welding machine on a stable surface to avoid unstable support.

Material Preparation: Get the materials ready for welding and place them within the welding machine’s operating range. Ensure the material surfaces are clean and free from oil or debris.

Starting the Portable 3 in 1 Handheld Laser Welder:

Power Connection: Plug the laser welding machine into a suitable power outlet and ensure the power cord is not visibly damaged.

Cooling System: If the laser welding machine requires a cooling system, make sure the cooling system is properly connected, and the coolant level is sufficient.

Starting Welding:

Workpiece Positioning: Place the workpiece that needs to be welded within the welding area and secure it using fixtures or supports. Ensure the welding position is correct, and the workpiece is stable.

Laser Focusing: Use the laser focusing function on the welding machine to focus the laser on the area that needs to be welded. Ensure the laser focus is clear and accurate.

Parameter Setup: Based on the material type, thickness, and welding requirements, set appropriate welding parameters on the machine, such as power, pulse frequency, etc.

Initiate Welding: Press the start button or trigger to begin the laser welding process. Keep the welding gun steady and avoid shaking during welding. The laser welding machine can be used for various operations such as butt welding, angle welding, overlay welding, especially for thin-walled materials and precision components. Consider adding wire depending on the workpiece.

Monitor Welding: During the welding process, carefully observe the welding area to ensure welding quality. If adjustments to welding speed or focus position are needed, make adjustments based on observation.

End Welding: When welding is complete, release the trigger to stop laser emission. Allow the welded area to cool down and handle the welded workpiece carefully.

Shutdown: After completing all welding tasks, turn off the laser welding machine, disconnect the power, and perform necessary maintenance and cleaning as per the instructions.

For more information about the industrial laser machine, how to use, applications and troubleshooting, please go to DPLASER’s YouTube channel, where we aim to provide you with professional knowledge about laser equipment.

Why Choose 3 in 1 Fiber Laser Welding Cutting Cleaning Machine

Versatility: The 3 in 1 handheld laser welder cutter rust remover possesses three distinct functions: laser welding, laser cutting, and laser cleaning. This versatility makes it an economically efficient solution for businesses that need to perform multiple tasks regularly.

Enhanced Efficiency: Laser welding, laser cleaning, and laser cutting all fall under the category of efficient laser processing techniques. Laser welding achieves precise and clean welds with minimal heat input, reducing deformation and rework. Laser cleaning offers an efficient and environmentally friendly surface cleaning method without the need for chemicals or abrasive materials. Laser cutting allows for rapid and precise cutting while minimizing material waste. Integrating these processes into one machine significantly boosts overall productivity and efficiency.

Cost-Effectiveness: By reducing the need for multiple machines, the purchase, maintenance, and repair costs can be lowered. Additionally, it simplifies production workflows, minimizes material handling, and optimizes processes, thereby reducing labor costs.

Precision and Quality: The 3-in-1laser welding machine can precisely control laser parameters such as power, speed, and focus to ensure consistent results at all times.

What are the disadvantages of a three-in-one fiber handheld laser welding machine?

High Cost: Compared to traditional welding equipment, three-in-one laser welding machines come with a higher price tag. This means both purchasing and maintaining a three-in-one laser welding machine require a substantial initial capital investment.

Energy Consumption: Laser welding machines require a significant energy supply, often involving high-power lasers and cooling systems. This can lead to increased energy consumption and operational costs.

Material Requirements: Laser welding demands specific material properties, often necessitating materials with high reflectivity and high refractive index. Mismatched materials can result in subpar welding quality or even an inability to weld.

How Much Does a 3 in 1 Portable Fiber Laser Welding Machine?

The portable lightweld laser welding machine price is influenced by various factors: laser power, the brand of the laser generator, machine specifications, optional accessories, etc.

Generally, the cost of a three-in-one laser welding machine tends to be higher as it offers more functions compared to dedicated machines designed for a single purpose (such as laser welding, laser cleaning, or laser cutting).

Basic entry-level handheld laser welding machines can range from $3500 to $10000. Models with advanced features, additional accessories, and higher output power may cost more.

Want to Buy Three-in-One Machine for Welding, Cleaning and Cutting

Laser welding, cutting, and cleaning three-in-one machines are high-speed, multi-functional processing equipment suitable for welding, cutting, and cleaning various metal materials. When purchasing this machines, it’s important to consider some factors:

1. Laser Equipment Performance: Choose a machine with a high-power laser source, a high-precision optical path system, and a stable control system to ensure processing efficiency and stability.

2. Safety: Laser welding, cutting, and cleaning three-in-one machines involve laser technology and require proper safety measures during use, such as wearing laser protective eyewear and setting up protective enclosures.

3. After-Sales Service: Choose manufacturers or suppliers with good after-sales service to promptly address any issues that arise during equipment usage. Additional skills include training in the use of equipment, maintenance and repair techniques, laser technology, etc.

Finally:

The multifunctional fiber laser welding cleaning and cutting machine has become an indispensable and important tool in modern manufacturing by virtue of its excellent technical characteristics and significant application advantages. It integrates welding, cleaning and cutting functions, providing manufacturers with more flexible and efficient production solutions. With the continuous development and innovation of technology, it is believed that the 3 in 1 handheld laser welder cleaner cutter will continue to drive the manufacturing industry to higher levels.