This comprehensive guide delves into the intricacies of using laser engraving glass bottles. From selecting the right laser marking equipment to crucial factors such as parameters, design considerations, and surface preparation, this article provides a wealth of insights for professionals and enthusiasts. Whether you’re a glass industry professional or an inquisitive reader, this guide equips you with invaluable knowledge to embark on successful glass laser marking.

Can You Use a Laser Engraver On Glass?

The answer is yes. Due to brittle qualities of glass, glass is particularly delicate during the engraving process, necessitating utmost care in glass engraving.

Laser marking machines can mark to a wide array of materials, glass included. However, the marking results on glass may vary compared to other materials. In the following, we will delve into some considerations when using laser marking machines for glass engraving and operational recommendations.

What kind of glass can be engraved by laser machine?

Borosilicate Glass: Borosilicate glass is a high-purity, low coefficient of expansion glass material, known for its excellent optical properties and chemical stability, making it suitable for laser engraving. Borosilicate glass is commonly used in the manufacturing of bottles, flasks, funnels, beakers, and measuring instruments.

Crystal Glass: Crystal glass is a premium glass material made from high-purity quartz and other components, resulting in high hardness.

Glass Ceramic: Glass ceramic is a specialized ceramic material that shares a glass-like appearance and texture. Its density and hardness make it suitable for laser engraving.

Tempered Glass: Tempered glass undergoes special processing to enhance its strength and impact resistance. Proper laser power and parameters need to be chosen during the engraving process.

Soda Lime Glass Mass-produced and used in bottles, drinking glasses, and windows. Comprised mainly of silica and calcium oxide, soda-lime glass has a lower melting temperature, making it an ideal choice for laser marking with minimal fracturing and chipping. The higher the quality of soda-lime glass, the better the engraving quality.

For some special glass, such as laminated glass or coated glass, special treatment may be required. Different types of glass have different physical and chemical properties, and laser engraving requires the selection of appropriate laser parameters and operating methods based on the properties of the glass and the desired engraving effect. Prior to laser engraving, it is advisable to conduct a small test run to determine the optimum engraving parameters and technique.

Why Use Laser for Glass & Ceramics Engraving?

High Precision and Detail: UV laser marking machine can produce very detailed markings suitable for engraving complex patterns, logos, text or images on glass surfaces. It is capable of achieving micron-level accuracy, ensuring the clarity and precision of the mark.

Durability and Stability: The markings produced by UV laser markers on glass surfaces are typically very durable and resistant to wear or fading. This makes it suitable for applications that require long-term durability, such as logos, product coding, etc. On glass products.

High Contrast: Laser marking machine creates a high contrast mark on glass, especially on clear or light colored glass. This allows the mark to be clearly visible against different backgrounds.

Rapid Processing: Laser markers allow for relatively fast processing speeds, which is beneficial for high volume production and efficient production lines.

Versatility: Laser marking technology allows for different types of markings on glass, including surface engraving, cutting, punching, patterning, and more.

Adaptable to Different Types of Glass: Laser engraving machine is applicable to different types of glass, including transparent glass, tinted glass, tempered glass, etc.

Environmentally Friendly and Pollution-Free: Laser etching machine for glass bottles is a non-polluting processing method that produces no chemical waste or by-products, which is in line with environmental requirements.

Compared to traditional glass marking processes, laser engraving technology can address production and time costs to a great extent, and the variety of engraved patterns is highly design-oriented. By choosing to use laser etched glass, you can enjoy the benefits of precision, consistency, speed and minimal environmental impact.

How to Improve the Clarity of Laser Marking Glass?

a. Adjust the power and frequency of the laser marking machine for a more pronounced marking effect.

b. Use special marking pigments or coatings to create a more distinct mark on the glass surface.

c. Perform marking on the backside of the glass to allow the mark to be seen when looking through the glass.

d. Add a contrasting background on the glass to make the mark more visible.

How to Get High Quality Laser Marking On Glass?

a. Ensure that the power and frequency of the laser marking machine are suitable for the glass material.

b. Ensure that the glass surface is clean, free from dust or stains.

c. Ensure that the laser beam of the marking machine is perpendicular to the glass surface for better marking results.

d. It is advisable to conduct some testing before marking to determine the optimal marking parameters and position.

To achieve a good laser marking effect on glass, pre-treatment of the glass is usually carried out:

Method 1: Before marking on glass, the glass surface can be moistened. Wet newspaper can be placed over the glass or the glass can be moistened with a cleaning solution to improve the engraving effect.

Method 2: Based on our sample tests, covering the glass surface with protective foil or tape before marking results in a good marking effect.

Tips for Using a Glass Laser Engraving Machine

a. Ensure the safety of the laser marking machine. Due to the high energy and temperature of the laser beam, appropriate safety measures need to be taken, such as wearing protective goggles and gloves.

b. Ensure the flatness of the glass surface. If the glass surface is not flat, it may result in poor marking effect or glass breakage.

c. Ensure the accuracy of the marking position. If the marking position is inaccurate, it may cause misalignment or incomplete marking on the glass.

Industrial Application of Laser Marking Machine for Glass

1. Cosmetic Bottles:

Laser marking can be used to engrave brand names, product information, and more on glass cosmetic bottles.

2. Wine Bottles:

Laser engraving on glass wine bottles can add unique value and appeal to the product. Laser marking can imprint winery names, wine details, patterns, and more on wine bottles.

3. Glass Cups:

Laser marking on wine glasses allows for personalized patterns, creating a uniquely tailored surprise for daily life.

4. Automotive Glass:

Laser marking can be applied to car rearview mirrors, windshields, and headlights to engrave vehicle logos, information, safety indicators, and more.

5. Architectural Decorative Glass:

Laser marking is suitable for decorating architectural glass windows, glass curtain walls, and more with frosted letters, patterns, and decorative effects.

6. Electronic Product Glass Panels:

Laser marking can be used to label brand names, model numbers, QR codes, and other information on glass panels of devices like smartphones and tablets.

7. Personalized Gifts:

Laser technology makes it easier to engrave names or unique patterns onto gifts. These keepsakes hold true emotional value and serve as beautiful decorative items.

How to Laser Engrave a Recycled Wine Bottle, Wine Glasses?

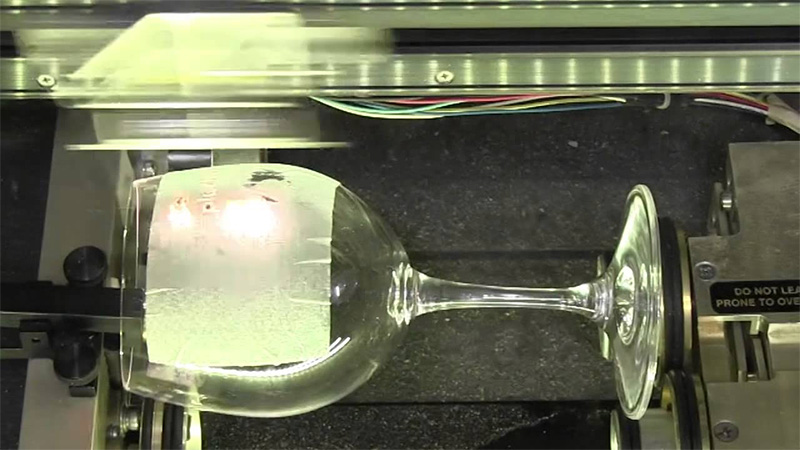

All you need to do is add a rotary attachment to your laser marking system. The rotary attachment can be easily inserted into the laser machine, allowing the glass to rotate during laser etching. It provides an effective method for engraving circle glass.

When engraving glass with handles, you can use a fixture or positioning device to secure the circular object. The choice of attachment depends largely on the item to be marked and the process. Install the appropriate attachment based on your marking requirements.

How to Laser engrave on Glass?

Preparation: Ensure that the laser engraving machine and the engraving material are both in normal working condition. Based on the characteristics of the engraving material, select the appropriate laser power and parameters.

Design the Engraving Pattern: Use Computer-Aided Design (CAD) software or image processing software to design or prepare the engraving pattern. This could be text, graphics, logos, etc., created or prepared according to requirements. During the design process, you can export raster or vector image format files from CAD software, such as BMP, GIF, JPG, PNG, TIFF, EPS, SVG, AI, etc.

Set Laser Power and Speed: Adjust the laser engraving machine’s power and speed according to the characteristics of the engraving material and the desired engraving depth.

Calibrate Focus and Engraving Plane: Ensure the laser engraving machine’s focus is correctly adjusted and calibrate the engraving plane to be parallel with the engraving material.

Preview and Adjust: Before actual engraving, preview the designed engraving pattern and adjust its position, size, and orientation to ensure the final result matches expectations.

Start Engraving: Based on the preset parameters and engraving pattern, initiate the laser engraving process. Ensure the relative positioning of the laser engraving machine and the engraving material remains stable to achieve a clear and precise engraving effect.

Inspect and Refine: After completing the engraving, check the depth and quality of the engraving result. If necessary, perform staining, polishing, or other post-processing techniques as required to enhance the visibility of the engraving effect.

It is recommended that testing and proofing be done prior to formal engraving to familiarize yourself with the operation and find the most appropriate marking settings.

How to Choose Glass Laser Engraving Machine?

Choosing the laser source and power is a critical decision when laser engraving glass, as it directly impacts the engraving effect and efficiency. UV and CO2 lasers are considered optimal methods for engraving glass.

Laser Type of Engraving Machine

CO2 Laser: CO2 laser marking machine are suitable for various non-metal materials, and they work well for shallower engraving depths. They are commonly used for creating scratches, patterns, or text on the surface of glass. Common CO2 laser power options typically range from 10~60W.

UV Laser Marking Machine: The marking of glass with UV laser engraving machines offers higher clarity, precision, and efficiency. This enables you to create intricate patterns and details on the glass surface, adding unique value and aesthetic appeal to glass products.

Femtosecond Laser: Femtosecond lasers produce extremely short pulses of laser light, which may reduce heat effects for brittle materials like glass, allowing for finer engraving.

Laser Marking Machine Power

Power Less Than 20W: Suitable for shallow surface engraving, such as creating simple patterns, logos, or text on the glass surface.

Medium Power (20~50W): Suitable for deeper engraving, capable of creating more pronounced patterns or text on the glass surface.

Power above 50W: Suitable for deep engraving or etching, allowing for deeper patterns or text to be engraved into the glass, and even enabling three-dimensional engraving.

The choice between these options will depend on factors such as the desired engraving depth, fineness of marking, and the specific glass material being used. It’s important to consider about your marking requirements and consult with experts to make the best decision for your glass engraving machine.

To achieve the best marking results, it’s essential to adjust the appropriate marking parameters and take necessary safety precautions. When marking on glass, consider using a UV laser marking machine as a priority. Compared to conventional marking methods, laser marking technology offers higher processing efficiency, producing visually intricate and refined markings on products.

Summary:

Laser engraving has a profound impact on enhancing glass craftsmanship across various industries, whether it’s intricate patterns, logos, or personalized designs. From branding marks to conveying emotion through personalized custom gifts, the assistance and limitless creativity provided by glass etching machine for home to small businesses are invaluable. Whether you’re a glass artisan, manufacturer or packaging designer, the laser engraving technology will open up a pathway to seamlessly blend commerce with artistry.