Laser cutting has become a game-changer for processing thin plates, offering unmatched precision, speed, and flexibility. Whether working with metals, plastics, wood or other materials, laser cutting machines deliver clean and accurate cuts, making them ideal for boosting production. In this article, we’ll explore the advantages of laser cutting thin sheet metal, its various applications, and helping you choose the perfect solution.

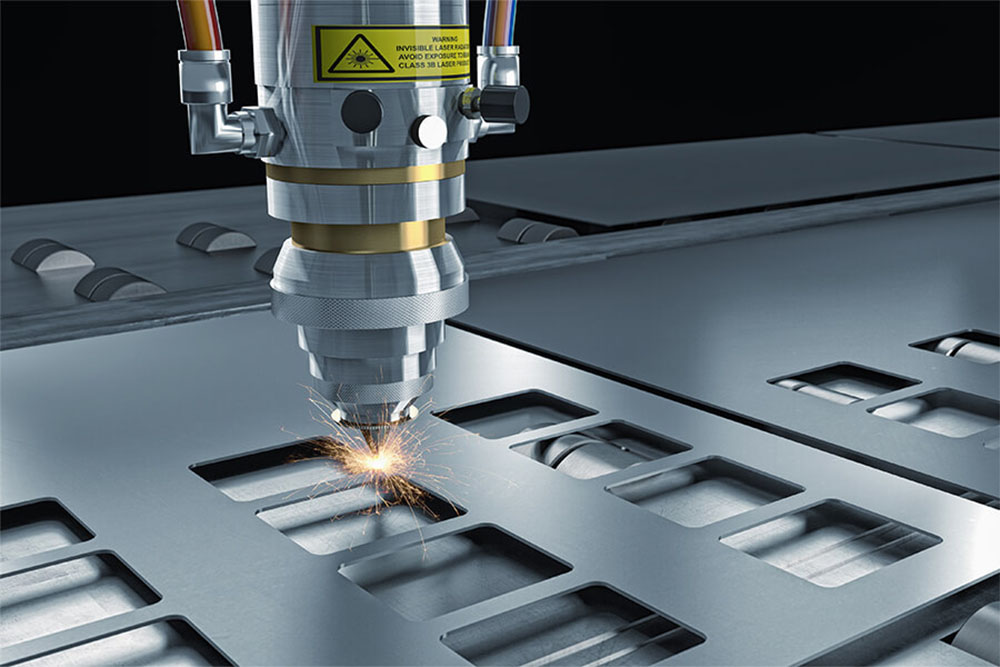

Laser cutting utilizes a high-energy laser beam to evaporate or melt metal materials, achieving precise cuts by controlling the laser beam’s output power and scanning path. This technology offers advantages such as fast cutting speeds, high precision, and superior cutting quality, making it widely applicable in industrial manufacturing, small enterprises, and personal fabrication.

Cutting Methods for Thin Metal Sheets

Laser Cutting

This method uses a high-energy laser beam focused on the surface of the metal sheet, converting light energy into heat to achieve cutting. Laser cutting is suitable for thin sheets and offers advantages such as high cutting precision, fast speed, and excellent cut quality. However, the laser cutting equipment initial investment is relatively high.

Plasma Cutting

This method melts and blows away the metal sheet by using a high-temperature plasma arc to achieve cutting. It is suitable for metal sheets of various thicknesses and offers fast cutting speeds at a lower cost. However, the cut quality is generally average and may require additional post-processing.

Water jet Cutting

This method utilizes a high-pressure water stream to cut through the metal sheet. It is applicable to metal sheets of all thicknesses, providing good cut quality. However, it is slower and more expensive compared to other cutting methods.

Laser Cutting Thin Metals Application

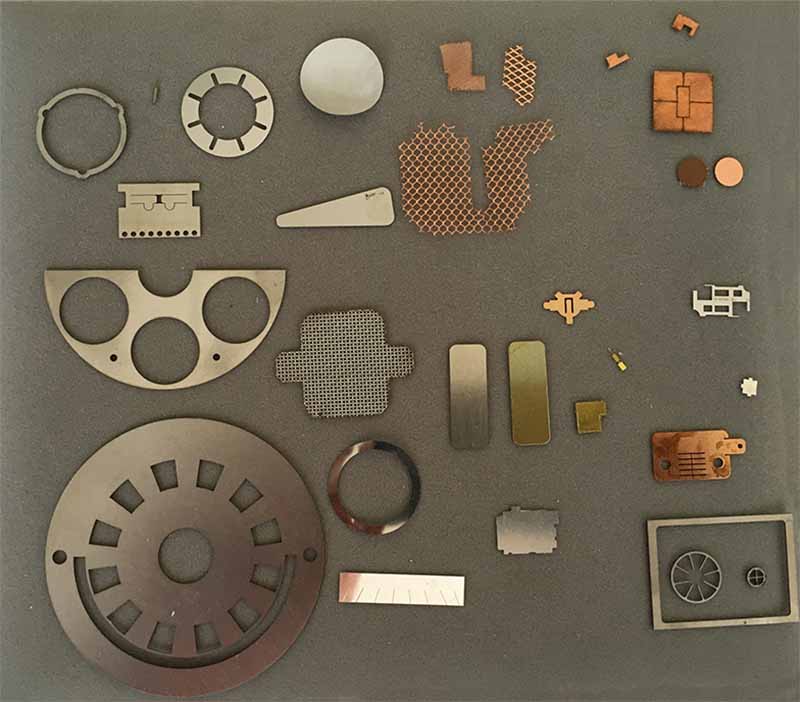

Laser cutting technology is widely applied in cutting and processing various materials, especially in scenarios that require high precision and efficiency. It is suitable for processing metal sheets, tubes, and irregular materials, particularly excelling at cutting thin sheets. The cutting thickness mainly depends on the focusing lens, laser wavelength, and power. In addition to handling various metal materials such as stainless steel, carbon steel, aluminum, and copper, laser cutting is also effective for non-metallic materials like plastic, rubber, and wood.

Laser cutting is ideal for thin metal sheets and foils because it can achieve clean cuts without the need for additional manual finishing. Thin sheets generally refer to metal plates with a thickness of 3mm or less, with common examples being standard steel and galvanized steel sheets. The range of applications for thin metal sheets is expanding, such as laser cutting thin stainless steel is used in the automotive parts industry, medical field, bathroom and kitchenware sectors, and hardware industries. Its cost is more affordable, and it offers excellent performance with simpler production processes.

Laser Cutting Thin Stainless Steel Metal Plates

Advertising Industry: Metal letters, signboards, and metal panels for advertising light boxes.

Kitchenware Industry: Storage containers, cookware, and tableware.

Hardware and Cabinets: Cabinets, enclosures, and electrical boxes.

Lighting Fixtures: Lamp shades, lamp bases, and other lighting decorations.

Elevator Manufacturing: Elevator doors, walls, and metal accessories for elevators.

Why Choose a Laser Cutting Machine for Thin Plates

Laser cutting technology uses a high-energy density laser beam to ablate and vaporize the material, cutting it into the desired shape. Compared to traditional mechanical and flame cutting methods, laser cutting of thin metals offers several advantages:

High Efficiency: Laser cutting has a fast cutting speed, allowing quick formation of the desired shapes. This significantly enhances productivity in industrial production.

High Precision: The laser beam’s small heat-affected zone ensures smooth cut edges and high cutting accuracy, meeting the requirements for precision cutting.

Minimal Thermal Deformation: Due to the narrow laser cutting kerf, fast speed, and concentrated energy, the heat transferred to the material is minimal, resulting in very little deformation.

No Need for Molds: Laser processing does not require any mold manufacturing. Once the product design is ready, laser cutting can begin immediately, allowing for quick turnaround times.

Strong Material Adaptability: Laser cutting is suitable for processing a wide range of materials, particularly metal materials.

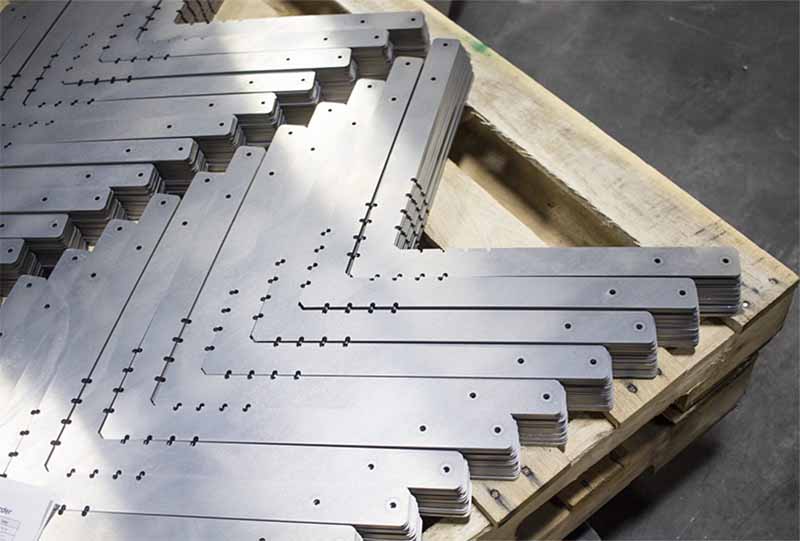

Material Savings: Laser cutting uses computer programming to nest different shapes on the same sheet, maximizing material utilization and minimizing waste.

How Thin Can a Laser Cutter Cut?

A laser cutter can cut metal sheets as thin as about 0.1mm, achieving high precision and excellent cutting quality. This makes it suitable for producing high-precision mechanical components, electronic device casings, and other delicate parts. However, for very thin sheets, the high energy density of the laser beam can easily cause spattering and deformation of the molten pool. Therefore, it is essential to select the appropriate cutting parameters and techniques for different sheet materials.

With the increasing use of thin steel plates in the market, there is greater emphasis on processing quality. For instance, when cutting materials, the results need to be smooth, with uniform thickness, and free of cracks or uneven surfaces. To achieve the best cutting results, it’s important to choose a laser cutting machine specifically designed for thin sheets.

Fiber laser cutting machines are ideal for cutting thin to moderately thick sheets with high precision and clean cuts. Generally, the higher the laser power, the wider the range of sheet thickness it can cut. However, beyond a certain thickness or power setting, the cutting quality may decrease, and slag formation can become more significant.

The Fiber Laser Cutting Machine for Thin Plate

Fiber laser cutting machine offers stable performance, smooth operation, and fast speed. High-performance flexible processing allows for high-quality cutting of any shape, including high-reflective materials like copper and aluminum. Equipped with an automatic exchange platform, enabling dual-platform work exchange, making it ideal for processing medium to thin plates.

Efficient Material Utilization: Optimized programming software increases material usage, reduces waste, lowers labor intensity, eliminates pre-cutting steps, and reduces clamping times, effectively improving processing efficiency.

Accelerated Product Development: Reduces mold usage, shortens product development cycles, enhances cutting quality and production efficiency, suitable for small-batch production, and prepares for large-scale manufacturing.

Simplified Processing Flow: High cutting precision with single-step forming, no molds required. Smooth cuts with no need for secondary processing, accelerating R&D and reducing costs.

Environmental Protection: Minimal waste, low noise, clean, safe, and pollution-free, significantly improving the working environment.

High-Rigidity Welded Bed Frame: Stable welded structure with optimized layout reduces thermal radiation in the cutting area, ensuring high strength and long-term stability of the machine.

F-Series Single-Platform Worktable: Modular design with excellent ventilation for quick disassembly and replacement, simplifying daily maintenance.

Intelligent Cutting Technology: Features multiple intelligent cutting technologies for medium and thin plates. “Fly Cutting” generates optimal paths for any shape, reducing unnecessary pauses. “Leapfrog” adjusts cutting head height to avoid obstacles, further improving efficiency.

User-Friendly Operating System: Intuitive interface with easy-to-use control panel and preset processing databases, simplifying operations.

Specifications and Compatibility: DPLASER F-Series processing size is 3000mm x 1500mm, with laser power from 1kW to 6kW, customizable per customer requirements. Advanced bus control system supports DXF, LXD, PLT, AI, Gerber, and other graphic file formats, enhancing flexibility and compatibility.

Ultraviolet (UV) Laser Cutter

Provides precise and delicate cutting with minimal kerf width and a low heat-affected zone. If your application requires clean cut edges, a UV laser is an excellent choice. Additionally, ultrafast femtosecond and picosecond lasers deliver optimal cutting quality and can be used for cutting metal and coated metal.

Picosecond Laser Cutting Machine

Capable of directly cutting film materials like PET, PI, and other transparent films. It also etches thin conductive metal films such as constantan, copper, aluminum, ITO, silver paste, and FTO. For metal materials below 0.2mm, like copper foil, aluminum foil, stainless steel, and alloys, the picosecond laser cutting machine achieves precise cuts with no burrs, low carbonization, and no deformation, making it suitable for military parts, photovoltaic copper foil, and more.

In summary, laser cutting machines offer a powerful solution for processing thin plates with unparalleled accuracy and efficiency. From electronic components to automotive parts, the applications are vast and varied. By understanding the advantages and exploring the laser machines for thin plate cutting, you can find the ideal equipment to enhance your production capabilities. Focus on the specific needs of your thin sheet laser cutting to select a machine that offers the best performance, quality, and value for your investment.、