What is UV Laser Marking Machine? The UV laser marking machine is a revolutionary device in the realm of marking and engraving. It employs high-energy ultraviolet light to achieve permanent marks on various materials, boasting attributes such as precision, versatility, and durability. By utilizing a high-intensity UV laser beam, these machines effectively remove or alter the surface material, resulting in precise marking. This process guarantees high resolution and clarity in the marks produced.

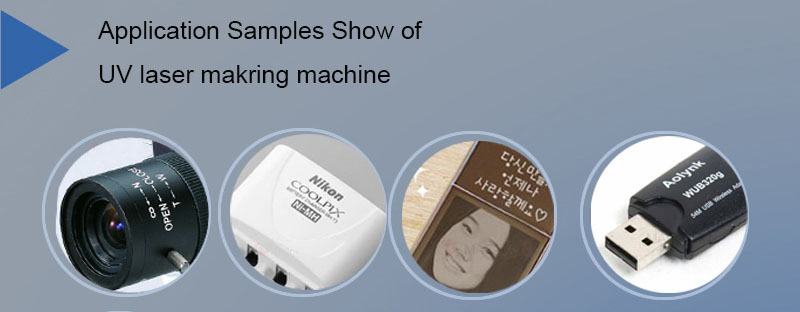

UV laser marking machines have been applied to the high-end market of ultra-fine processing, cell phone buttons, electronic cigarettes, cosmetics, pharmaceuticals, food and glass, silicon wafers and other special materials that are sensitive to heat or require extremely high precision; flexible PCB board marking, scribing; silicon wafer, blind hole processing; LCD liquid crystal glass, glassware surface, metal surface coating, plastic buttons, electronic components, gifts, communication equipment and construction materials, and many other fields.

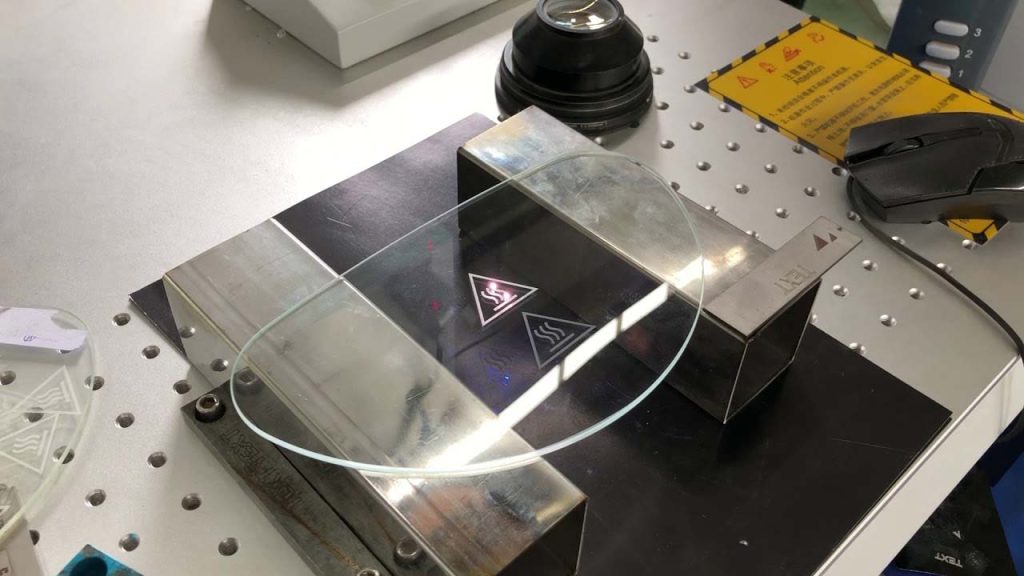

Can I Use UV Laser Marking Machine For Glass?

If you want to mark on glass surfaces, a UV laser marker is an excellent choice. Compared to other lasers, UV lasers efficiently remove particles and thin layers from the glass surface, resulting in clear, high-quality marks. Additionally, the shorter wavelength range of UV lasers allows for higher resolution marking.

Marking:

UV laser marking machines utilize high-energy density laser beams to achieve permanent marking on glass products. Whether its text, patterns, or QR codes, UV laser marking machines can complete marking tasks with extremely high precision and stability.

Engraving and Cutting:

UV laser marking machines can perform cutting, engraving, and other processing techniques on glass surfaces, enabling precision machining and personalized customization. In the field of micro-processing, UV laser marking machines can achieve micrometer-level processing, making minor changes or micro-hole processing on glass surfaces, used in the manufacturing of micro-devices, biochips, and other areas.

Glass Product Processing:

UV lasers can be used for processing glass products such as bottles, cups, etc.

Surface Texture Treatment:

UV laser marking systems can generate various textures on glass surfaces, such as frosted, silk-screened, inlaid patterns, etc., thereby altering the optical properties and tactile feel of the glass surface, enhancing the aesthetics and added value of glass products.

UV Laser Marking Machine for Plastic

The UV laser marking machine utilizes ultraviolet laser technology to code the surface of objects using high-energy ultraviolet beams. UV lasers focus the laser beam through an optical system to achieve high-quality marking effects. This type of UV laser beam has a small diameter, allowing for clear marking of small fonts and intricate patterns, making it ideal for marking beverage plastic bottles.

Why Use UV Laser Marking Machine for Plastic Bottle Industry?

Efficient Marking Speed and Quality:

With its short ultraviolet wavelength and small focused spot, the UV laser can achieve extremely fine and clear marking on the surface of plastic bottles, including small fonts, complex graphics, barcodes, or QR codes. This ensures precise and aesthetically pleasing identification. On high-speed production lines, UV laser marking machines guarantee accuracy and consistency, enhancing production efficiency.

Durability and Safety:

The marks produced by UV laser marking machines exhibit high durability, resisting wear, contamination, or blurring, thus maintaining clarity over time. This is crucial for beverage plastic bottles, which undergo challenges during transportation, storage, and consumption, requiring marks that remain clear for extended periods.

Environmental and Health Benefits:

The marking process of UV laser marking machines doesn’t require ink or chemical substances, thus producing no pollutants and complying with environmental regulations. Moreover, UV laser marking is a non-contact marking method that doesn’t damage or contaminate the surface of plastic bottles, ensuring product safety and hygiene.

Personalized Customization:

UV laser marking machines enable personalized customization of marks, including dates, production batches, brand logos, etc., facilitating brand marketing and product management.

Wide Applicability:

UV laser marking machines are suitable for various types of plastic materials, including PET, PP, PE, etc., and can be applied to plastic bottles of different specifications and shapes in the beverage industry, whether it’s the bottle body or cap, achieving high-quality marking.

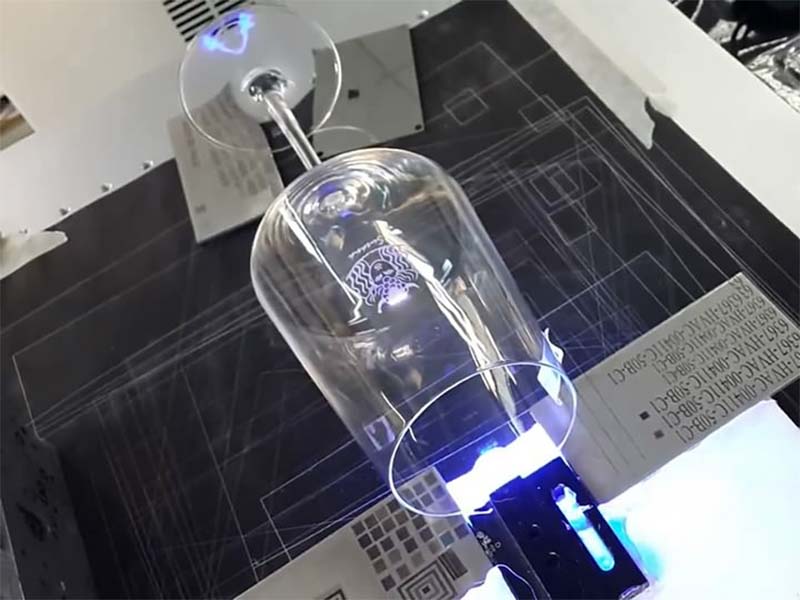

3D UV Laser Marking Machine

The 3D UV Laser Marking Machine is capable of creating three-dimensional, depth-enhanced patterns and text on object surfaces. By combining a rotary device with 3-axis laser engraving technology, unparalleled three-dimensional effects can be achieved. This combination utilizes the laser’s ability to move in three directions, while the rotary device allows the workpiece to rotate in another dimension. This synergy enables precise laser engraving throughout the entire three-dimensional space.

The emergence of 3D laser marking machines marks a significant advancement in the field of laser marking. It removes the limitation of surface shapes being confined to a flat plane, expanding the capability to mark on three-dimensional surfaces efficiently. This advancement facilitates laser marking and surface microstructure manufacturing on three-dimensional curved objects with high efficiency.

3D Dynamic Focus UV Laser Marking Machine

3D dynamic focus UV laser marking machine is an advanced tool used for precision marking on various materials. Unlike traditional laser marking machines, this machine utilizes UV (Ultraviolet) laser technology, which offers very fine details and high-resolution marks, making it suitable for applications where precision is crucial, such as LCD liquid crystal glass, medical devices, and electronic component.

The 3D Dynamic Focus features can adjust the focal point of the laser beam dynamically, allowing it to adapt to the contours and shapes of the material being marked. This capability enables the machine to produce consistent, high-quality marks even on uneven or curved surfaces.

This desktop UV laser marking machine adopts advanced digital 3-axis dynamic focusing technology with fast marking speed, as well as 3D curved surface stereo marking and large format marking functions. It is mainly applied to the marking needs of circular and curved objects such as LED bulbs, water bottles, mugs and eggs.

- The UV laser has a shorter wavelength and a smaller focusing spot, which can realize ultra-fine marking effect. The use of high-speed digital vibrating mirror, marking speed, high efficiency and high precision.

- The UV laser marking machine can not only mark on the plane, but also realize three-dimensional curved surface three-dimensional marking, making the marking effect more rich and diverse. It can accurately focus the spot within the height range of 0 to 150 mm to ensure the consistency of the marking effect.

- The use of advanced digital three-axis dynamic focusing technology improves the marking speed, and zoom control is more real-time, while ensuring the uniformity of the focusing spot, thus improving the quality and efficiency of marking.

- UV laser marking machine adopts modular design, compatible with domestic and foreign mainstream fiber laser, greatly improving the adaptability of the product, so that users can choose the right laser according to the needs of different marking needs.

- Equipped with a marble working platform, it has excellent shock resistance and stress resistance, high flatness and good stability, which can ensure the accuracy and stability of the marking process.

- The UV laser marking machine is equipped with powerful software, which can import the output graphics of mainstream 3D design software and edit 3D graphics, and also has the function of converting 2D graphics to 3D, which makes the operation simple and convenient, and allows the user to easily realize personalized marking needs.

Key Features of 3D UV Laser Marking Machine

Variable Focus to Achieve Three-Dimensional Marking

3D marking technology with variable focal length function, can realize the complex three-dimensional surface for accurate marking, breaking through the limitations of 2D marking cannot deal with curved surfaces, especially for cylinders and other non-planar objects, you can one-time completion of the entire marking process, significantly improve work efficiency.

More Suitable for Deep Engraving

Compared with the traditional 2D marking, in the deep carving application, 3D marking has more advantages. 2D marking in the depth of the carving, with the laser focus upward, the energy attenuation is serious, affecting the effect of carving and speed. While 3D marking without the use of motorized elevator to adjust the focus, to maintain a good focus state, both to enhance the quality and efficiency of deep engraving, but also to reduce costs.

Larger Range and Finer Engraving

3D marking through the front focus and back focus mode, not only to achieve a large area marking, but also to achieve a finer engraving effect. In the front focus mode, the equipment uses a large-size deflector lens, which makes the laser spot focus smaller and has higher energy density to meet the demand for high-precision marking over a large area.

Rich Black White and Color Marking Effects

3D marking technology can also achieve rich black and white and color marking effects. For example, in the anodized aluminum surface marking black, through the regulation of laser frequency, focus distance and other factors, can create a variety of colors and grayscale effects. Even on occasions where curved surface marking is not required, 3D marking machines can also provide more detailed and rich color performance for 2D flat marking.

Choose Dapeng Laser as Laser Marking Machine Supplier

DPLaser not only offers a comprehensive range of laser marking and engraving solutions but also provides exceptional customer-focused services to ensure a seamless experience for clients.

1. Customization: We offer customization services to tailor our laser marking systems to meet specific application needs. Whether it’s adjusting laser parameters, integrating additional features, or designing specialized fixtures, our team works closely with clients to deliver personalized solutions.

2. Technical Support: Our dedicated team of technical experts provides comprehensive support throughout the entire lifecycle of our products. From installation and setup to troubleshooting and maintenance, we offer prompt assistance to address any technical issues and ensure optimal performance of our laser marking systems.

3. Training Programs: To empower our clients with the knowledge and skills to maximize the potential of our laser marking machines, we offer training programs conducted by experienced professionals. These programs cover various aspects such as machine operation, software usage, safety protocols, and maintenance procedures, enabling clients to operate our systems confidently and efficiently.

4. After-Sales Service: Our commitment to customer satisfaction extends beyond the initial purchase. We provide reliable after-sales service to address any concerns or queries that clients may have.

5. Application Support: We offer expertise and guidance to assist clients in leveraging the full capabilities of our laser marking solutions for their specific applications. Whether it’s selecting the most suitable laser parameters, optimizing marking parameters for different materials, or exploring innovative marking techniques, our team provides valuable insights and support to help clients achieve their marking objectives effectively.

Dapeng Laser specializes in providing solutions for fiber laser marking machines, UV laser marking machines, laser 3D marking, 3D laser engraving, 3D curved surface laser marking machine systems, as well as applications for three-dimensional dynamic focusing laser marking machines and automated laser marking systems.

Summary

In this article, we take an in-depth look at the principles, applications and advantages of UV laser marking machines. From glass marking, plastic marking to an introduction to 3D dynamic UV laser marking machines, we hope to have provided you with comprehensive knowledge. The high precision and efficiency of the best UV laser marking machine can help you achieve greater success in product design and manufacturing.