Laser welding technology continues to evolve, providing manufacturers and fabricators with more efficient, precise, and flexible solutions than ever before. Whether you’re looking for a compact handheld welder for on-site repairs or a high-performance CNC laser welding system for automated production, today’s market offers a solution for every need. In this article, we explore the best laser welder 2025 to help you find the ideal option for your application.

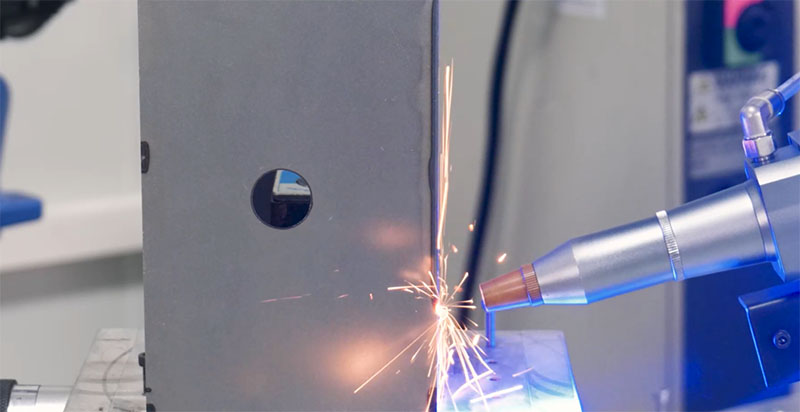

The CNC laser welding machine locally heats the material in a tiny area by means of high-energy laser pulses, and uses the energy of the laser radiation to spread to the inside of the material through heat conduction, thus melting the material and forming a specific molten pool, and finally realizing the welding purpose. This type of welding is characterized by high precision and a small heat-affected zone, and is able to meet the high demands of welding tasks.

Laser welding can be performed with or without filler material, and some laser welding machines are even equipped with a wire feeder. Since laser welding produces a relatively small heat-affected zone, it minimizes warping to the greatest extent, making it particularly suitable for joining complex and thin materials.

Types of CNC Laser Welding Machines

Fiber Laser Welding Machine

This type of welding machine transmits the laser beam through optical fiber, offering high efficiency and precision. It is widely used in high-accuracy welding tasks and supports long-distance transmission, making it suitable for most metal welding applications. Fiber laser welding machines can be further divided into handheld fiber laser welders and automated platform fiber laser welders.

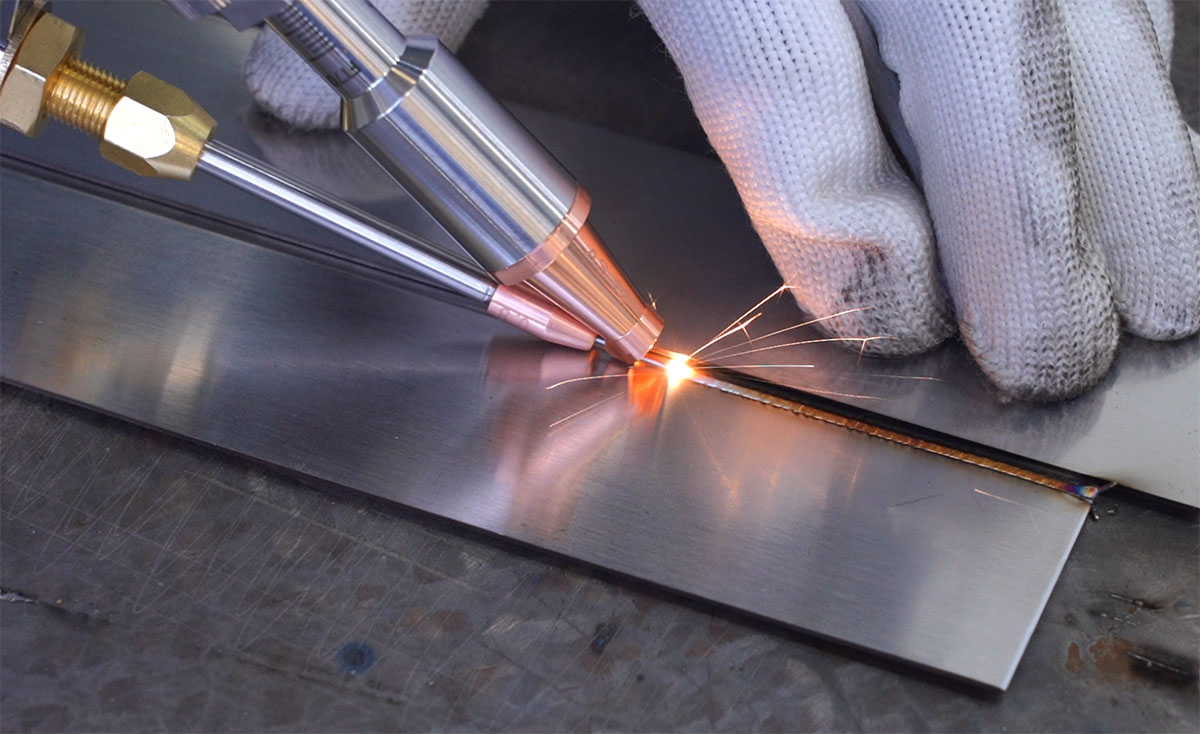

- Handheld laser welding machines offer flexible operation, ideal for welding complex or irregular workpieces.

- Automated platform laser welding machines deliver higher efficiency, making them suitable for batch production.

Nanosecond Pulse Laser Welding Machine

This welding machine uses nanosecond-level laser pulses, making it ideal for micro-welding and high-precision applications. It is commonly used in fields such as electronics, medical devices, and precision instruments.

QCW Fiber Laser Welding Machine

Utilizing a quasi-continuous wave (QCW) mode, this machine provides high peak power output. It is well-suited for applications requiring high melting rates and deep penetration welding, particularly where high-strength welds are critical.

YAG Laser Welding Machine

Powered by a solid-state laser source, YAG laser welders are suitable for welding thicker materials. Although their efficiency is lower compared to fiber laser machines, they remain a robust option for heavy industry and manufacturing applications due to their strong welding capabilities.

Advantages of Handheld Laser Welding Machines

High Welding Quality

The laser beam is precisely controlled by an advanced system, ensuring narrower weld seams, deeper penetration, and uniform heat distribution. This results in stronger joints while minimizing the impact on surrounding areas. The reduced heat input significantly lowers thermal deformation and stress, preserving the original properties of the workpiece.

Fast Welding Speed

Thanks to the high energy density of the laser, materials melt rapidly, allowing for much faster welding compared to traditional methods. The shorter heat application time further reduces the risk of thermal distortion and improves overall processing efficiency.

Adaptability to Complex Requirements

With flexible control of the laser head and adjustable focus, handheld laser welders can easily operate in tight spaces, inner corners, and complex angles. This makes them particularly suitable for welding irregular or intricately shaped workpieces.

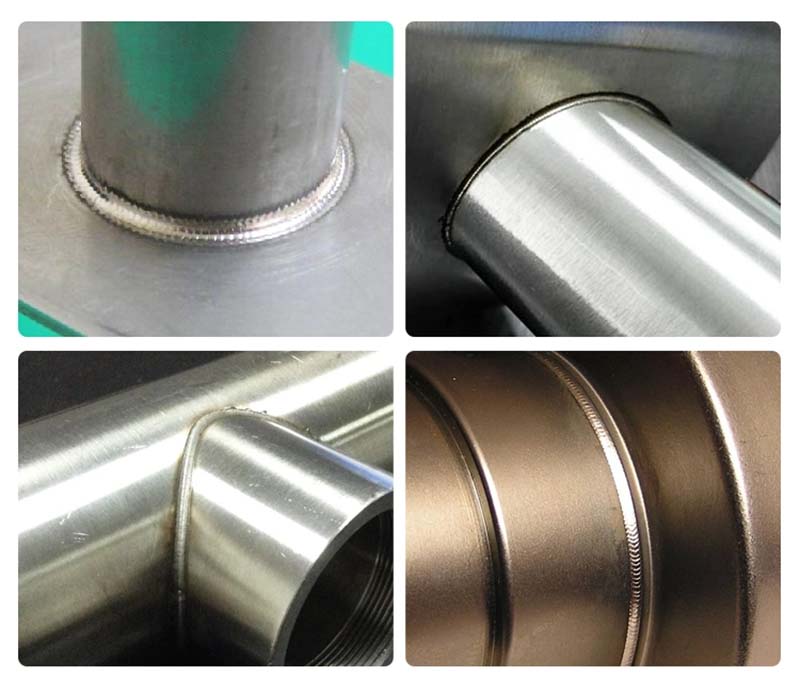

Clean and Consistent Welds

Handheld laser welding offers minimal energy fluctuation during operation, resulting in smooth and aesthetically pleasing weld seams. Most welded parts require little to no post-processing, such as de-burring or polishing, which saves both time and labor costs.

User-Friendly and Easy to Operate

The intuitive interface allows operators to quickly select pre-configured settings for different materials, eliminating the need for extensive preparation. Even users with minimal experience can learn to operate the system efficiently, making it much more accessible than traditional welding techniques.

The Best Laser Welding Machine 2025

The output power of handheld laser welding machines typically falls within the 1000W to 6000W range, directly influencing both welding speed and penetration depth. While higher power enhances welding performance, it is crucial to select a level that corresponds appropriately to the thickness of the material being processed.

The cooling system is another critical factor in maintaining reliable operation. Air-cooled designs offer greater portability, whereas water-cooled systems provide improved stability and are better suited for extended use.

Size and weight are also important. Portable compact welding machines are ideal for small workshops, while automated laser welding platforms are better suited for industrial mass production.

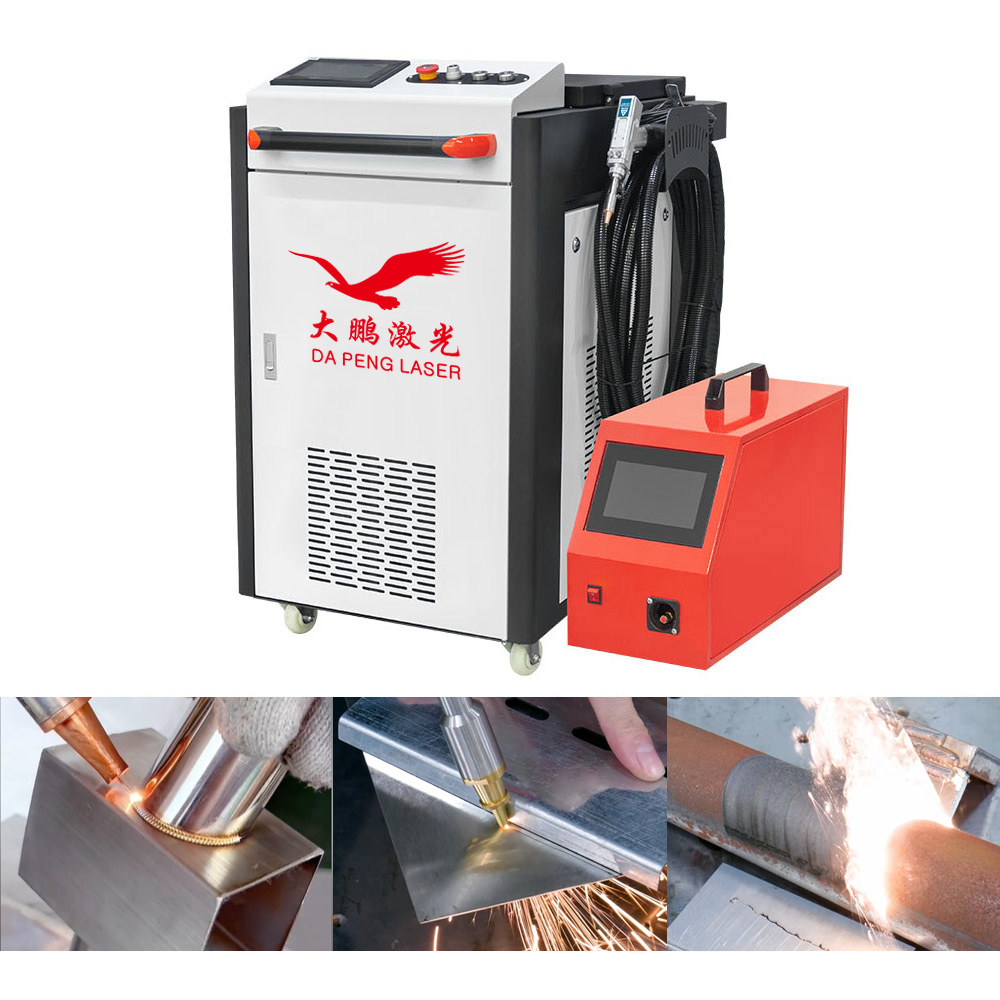

3-in-1 Handheld Laser Welding Machine

The 3 in 1 handheld fiber laser welding machine is an innovative and versatile solution that combines laser welding, laser cleaning, and laser cutting into a single compact device. With its multifunctional capabilities, it is rapidly becoming an essential tool in modern manufacturing.

All-in-One Design: A Comprehensive Solution for Multiple Processing Needs

This cutting-edge system integrates laser welding, cleaning, and cutting into one machine—enhancing both versatility and productivity. The innovative design not only meets a wide range of processing requirements but also saves workspace, reduces equipment investment, and boosts overall efficiency.

- Laser Welding: Ideal for stainless steel, aluminum alloys, copper, and various other metals. It delivers clean, strong welds with minimal seam issues, making it especially suitable for thin-walled metal welding.

- Laser Cleaning: Effectively removes rust, oil, and oxidation layers from metal surfaces using high-energy laser beams—without chemicals, contamination, or damage to the base material. This process is cost-effective and environmentally friendly.

- Laser Cutting: Suitable for cutting metal and alloy sheets under 3mm thick. Primarily designed for auxiliary cutting, not intended to replace specialized cutting equipment.

Handheld Design: Flexible and Convenient

The handheld laser welding machine design offers unmatched flexibility, allowing operators to adjust angles and positions during welding. It’s especially useful for irregular, large, or hard-to-reach components, enabling precise and efficient operations in diverse environments.

Smart Control System: Simplified Operation

An advanced intelligent control system automatically adjusts laser power, pulse frequency, and welding speed to ensure consistent quality while streamlining the workflow. Real-time monitoring and fault diagnostics ensure stable and smooth operation with minimal manual intervention.

Eco-Friendly and Energy-Efficient

Unlike traditional welding methods, laser welding produces no harmful gases or smoke, offering a cleaner and more sustainable alternative. It’s a green technology that contributes to safer and more responsible manufacturing.

Exceptional Welding Quality

With high precision and minimal heat-affected zones, the 3 in 1 laser welder significantly enhances weld quality. It produces narrow seams with smooth surfaces, minimal deformation, and high joint strength—often eliminating the need for post-processing.

Wide Applications across Multiple Industries

This machine excels not only in conventional metal welding tasks but also in applications across home appliances, components manufacturing, metal fabrication, construction, and machinery production. Whether working on fine, precision parts or large, complex structures, the 3-in-1 handheld laser welding machine delivers outstanding results.

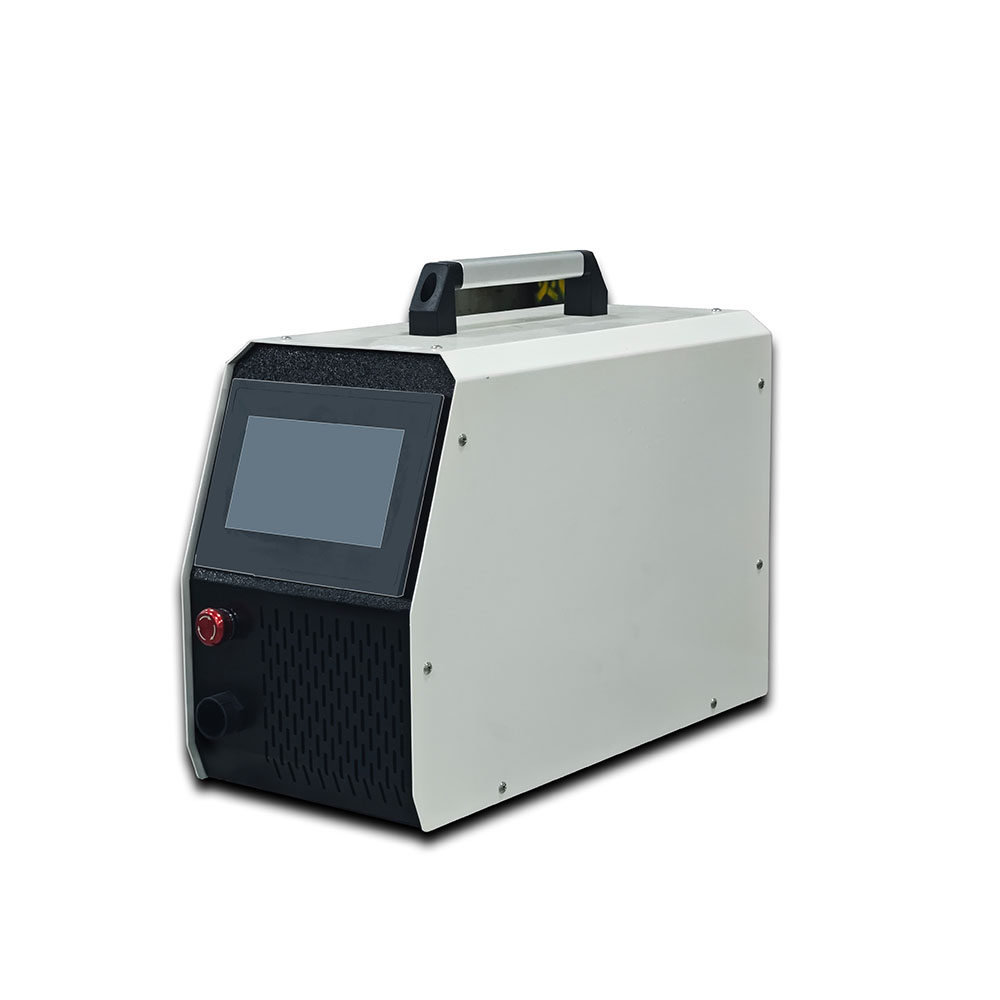

Air-Cooled Portable Laser Welding Machine

The 700W portable handheld laser welding machine combines innovative design and cutting-edge technology, offering superior welding efficiency and precision while maintaining portability and ease of use. Its handheld design enhances flexibility, making it an ideal choice for welding in tight spaces and hard-to-reach areas, further expanding its versatility across various industries.

Easy to Move

Featuring an air-cooled design, this laser welder is only 25KG, lightweight and portable, making it easy to carry and operate. Even during prolonged use, it minimizes fatigue, greatly improving worker comfort and flexibility. Whether in the workshop, factory, or on-site, it offers enhanced mobility and operational flexibility.

Compact Design

With its compact structure, the machine saves valuable space. Its lightweight build not only ensures ease of operation but also optimizes storage space, making it ideal for environments that require frequent movement and flexible use.

Wide Range of Applications

This laser welding machine is suitable for a variety of materials and is extensively used in industries such as sheet metal fabrication, kitchen cabinets, enclosures, handrails, elevators, display shelves, doors and windows, advertising models, and stainless steel products.

Key Features

- Simple Operation: The intuitive design of this handheld laser welder makes it easy for users to get started without the need for specialized training, enabling quick and efficient operation.

- High Welding Efficiency: Compared to traditional TIG welding, the 700W air-cooled laser welding machine increases welding speed by over three times, significantly boosting work efficiency.

- Consumable-Free Welding: No filler wire is needed for most welding tasks, but the machine can also be equipped with an automatic wire feeder for seamless wire integration when necessary.

- Smooth and Aesthetic Welds: The laser welding process produces smooth, neat seams, greatly reducing the need for post-welding polishing and cleaning.

Cheap Laser Welder Reviews

“This air-cooled handheld laser welder has become an essential tool in my workshop for metal welding tasks. Its lightweight design makes it easy to carry and operate, making it perfect for a wide range of welding jobs. It delivers strong, high-quality welds even on steel and aluminum.”

— Andrew Horan

“As a welding beginner, I found this machine incredibly easy to use. It doesn’t require any additional shielding gas, which makes it super convenient. The performance exceeded my expectations. Given its affordable price, it’s a great value for money. I haven’t used it for heavy-duty welding yet, but after just a few practice runs, I can already tell it’s one of the best portable welders I’ve ever seen.”

— Joshua C.

“It’s handheld laser welding gun performs exceptionally well. It has a solid build and a compact design, making it easy to transport. It’s especially effective for applications like auto repair. Simple to operate and highly efficient, it handles various welding challenges with ease. Whether you’re a beginner or a professional, you’ll definitely benefit from its capabilities.”

— M. Schulz

Precision Platform Laser Welding Machine

The platform automatic laser welding machine offers superior precision, consistency, and efficiency compared to handheld welding machines. Designed for high-volume and high-accuracy applications, this system ensures stable weld quality with minimal operator intervention. The platform laser welding system allows for complex multi-axis movements, enabling the welding of intricate parts with exceptional repeatability. Additionally, it significantly boosts production throughput while reducing material waste and post-processing needs.

The platform automatic laser welding machine integrates advanced beam shaping and focusing technologies, allowing for ultra-fine laser spot control down to tens of microns. This enables highly accurate welding with uniform energy distribution and minimal deviation, making it especially suitable for ultra-thin materials such as metal foils with a thickness under 0.1 mm.

Multiple Welding Modes

The machine supports various welding modes including spot welding, butt welding, seam welding, and seal welding. It is designed for thin-walled materials and precision components, offering flexible solutions for diverse welding applications.

Multi-Axis Servo Welding Table

Equipped with a high-precision, multi-axis servo motion platform, the system delivers accurate positioning and responsive movement. Its anti-vibration design ensures process stability, allowing automated and precise welding without manual repositioning of the workpiece.

Weld Monitoring System

A high-definition CCD display enables clear real-time monitoring of the welding process. Controlled via an industrial PC and dedicated welding software, the system supports adjustable parameters and multi-level waveform control to ensure consistent weld quality.

Intelligent Control System

The integrated CNC system supports programmable welding paths and parameters for fully automated operation. Real-time status monitoring via built-in sensors and CCD systems ensures stable and reliable welding performance.

Robotic Integration

Compatible with multi-axis robotic systems, the welder can execute complex welding paths automatically. This makes it ideal for flexible, multi-variety, and small-batch production, greatly enhancing the level of automation and adaptability on the production line.

High-Efficiency Welding

Welding speeds are significantly faster than traditional methods, with each weld point completed within seconds. This rapid processing capability dramatically improves production efficiency and meets the demands of high-throughput manufacturing.

Enhanced Production Performance

The automated laser welding system delivers consistently high-quality welds, reducing scrap rates and rework. It effectively increases the yield of finished products and boosts overall production efficiency.

The Best Laser Welding Machine 2025 Price

Handheld Laser Welding Systems

Perfect for small-scale operations and repair tasks, handheld laser welders are lightweight, versatile, and budget-friendly. They are easy to operate, making them an excellent choice for both beginners and professionals.

Estimated Price Range: USD $3,000 – $8,000

Automatic Laser Welding Machines

Designed for small to mid-sized production lines, these machines offer enhanced automation, greater stability, and consistent weld quality. They strike a balance between performance and cost, making them a solid choice for expanding businesses.

Estimated Price Range: USD $10,000 – $15,000

Industrial Robotic Laser Welding Systems

Tailored for high-volume, large manufacturing, these systems provide full automation and seamless integration with industrial robotics. Ideal for demanding production environments that require precision and efficiency on a large scale.

Estimated Price Range: Starting from USD $20,000 and up

Factors Affecting Laser Welding Machine Prices

Power Output:

Higher power levels generally lead to higher costs, as they enable faster welding speeds and compatibility with thicker materials.

Brand Reputation:

Well-known brands and high-quality equipment typically come at a premium but offer greater reliability, performance, and after-sales support.

Laser Source Type:

Fiber laser sources are more expensive than other types, such as diode or YAG lasers, due to their superior precision and efficiency.

Level of Automation:

Advanced automation features—such as auto-feeding, auto-positioning, or robotic integration—will increase the overall cost of the machine.

Customization Requirements:

Custom-designed machines to meet specific needs (e.g., special fixtures or unique material compatibility) often involve additional expenses.

Technology and Control Systems:

More sophisticated control systems and technologies—such as PLC control, path planning software, or intelligent sensors—can significantly raise the equipment’s price.

Frequently Asked Questions about Laser Welding Machines

What metals can a laser welding machine weld?

Laser welding machines are widely used for welding various types of metals:

Stainless Steel: Suitable for most types of stainless steel.

Carbon Steel: Including low-carbon steel, medium-carbon steel, and high-carbon steel.

Aluminum Alloys: Especially alloys with good weld ability.

Copper and Copper Alloys: Such as brass, bronze, etc. However, due to copper’s high thermal conductivity, higher laser power is required during welding.

Nickel and Nickel Alloys: For example, Monel alloy.

Titanium and Titanium Alloys: Titanium alloys are widely used in aerospace, aviation, and medical devices.

Can a laser welding machine weld iron?

Yes, a laser welding machine can weld iron, including low-carbon steel and regular carbon steel. During welding, the laser precisely controls the heat input, avoiding excessive heat-affected zones and ensuring high-quality welds.

Can a laser welding machine weld aluminum?

Laser welding machines can weld aluminum, but since aluminum has high thermal conductivity, higher laser power is required to overcome the rapid heat dissipation. Additionally, aluminum may have an oxide layer, so auxiliary gas is typically needed to prevent oxygen from the air from affecting the weld quality.

In conclusion, when searching for the best laser welding machine 2025 price, it’s important to balance both cost and functionality. With a variety of options available, from cost-effective handheld models to advanced industrial robotic systems, you can find the ideal solution that fits your production needs and budget. Understanding factors like power, automation, and customization will help you make an informed decision. Don’t miss the opportunity to enhance your welding projects with the latest technology. Act now and contact us to share your manufacturing process and get the best customized laser welding machine.