A brand logo is a vital symbol of corporate identity—it not only represents the brand name but also strengthens customer trust and leaves a lasting impression in the market, enhancing the company’s professional image. Beyond brand promotion and recognition, a logo also plays a key role in protecting intellectual property and ensuring product authenticity. A laser engraving logo machine is specifically designed to create permanent, high-precision markings that elevate brand identity and product value. Capable of engraving on metals, plastics, glass, and coated materials, it delivers crisp, wear-resistant results that surpass traditional printing and labeling methods.

Among various logo marking methods—such as laser engraving, inkjet printing, chemical etching, pad printing, or embossing—each has its own advantages and limitations. However, handheld laser engraver for metal has emerged as the preferred choice for brand identification thanks to its portability, permanence, and versatility.

A laser marking machine works by focusing a high-energy laser beam onto the surface of a material, triggering instant physical or chemical changes that result in sharp, long-lasting marks. This technology is compatible with metals, plastics, ceramics, wood, and many other materials, allowing for efficient and detailed engraving that meets both brand protection and aesthetic requirements.

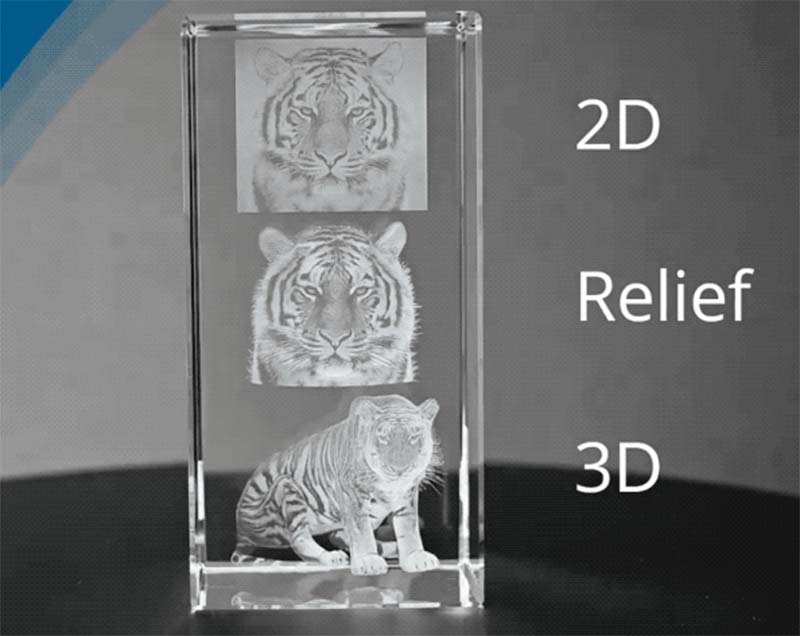

What was once the work of skilled craftsmen is now accessible to anyone: with the laser engraving machine for beginners, individuals can easily engrave their ideas and creativity onto objects—making it an excellent tool for DIY projects. From a commercial perspective, laser engraving also enables businesses to offer customized patterns for their customers, catering to personalization demands and creating new profit opportunities. This makes it especially valuable for design studios, educational workshops, and creative industries.

Features of Handheld Laser Engraver for Metal

Permanent Marking

One of the biggest advantages of laser engraving is its durability. Excluding the natural properties of the material itself, laser marks remain permanent, resistant to fading, and can withstand harsh environmental conditions.

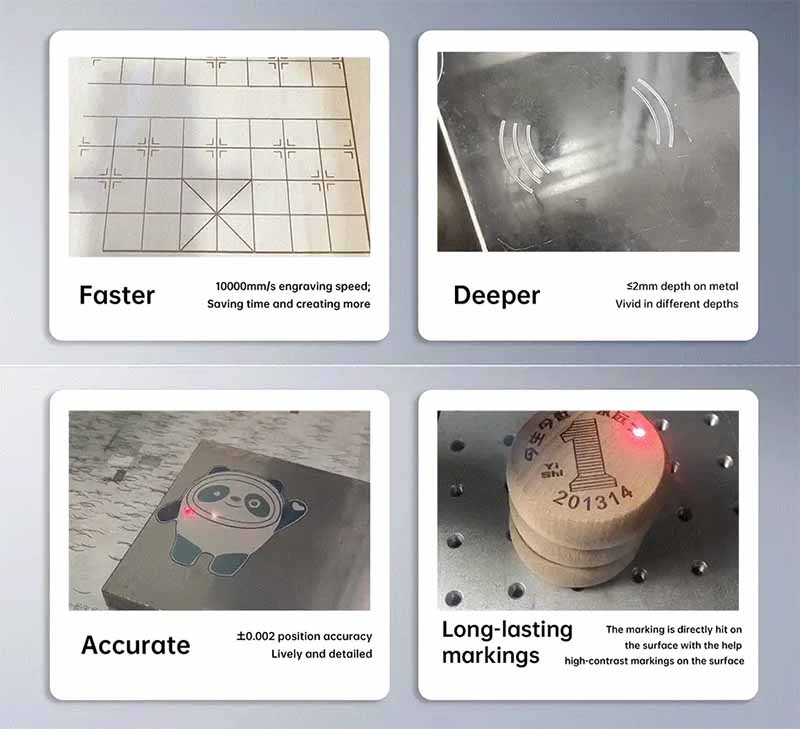

Ultra-High Precision Engraving

Equipped with advanced fiber laser technology, the handheld laser engraver delivers engraving accuracy up to ≤1mm. Whether it’s brand logos, patterns, or text, it ensures fine, sharp, and detailed results on materials such as flooring, tiles, and more—significantly enhancing product quality and brand image.

Portable Handheld Design

Compared with traditional desktop equipment, the handheld laser engraver offers greater flexibility and portability. It adapts easily to different positions and spatial requirements, making it ideal for marking complex shapes, hard-to-reach areas, large components, heavy parts, or immovable products.

Easy to Operate

Designed with ergonomics and a user-friendly interface, the handheld laser engraver is simple to learn and operate. This minimizes training costs, reduces operator error, and improves efficiency. Whether in a production workshop or a maker space, users can quickly master the machine with minimal learning time.

High Efficiency & Energy Saving

While ensuring high-speed processing, the handheld engraver consumes significantly less energy. Even during long periods of continuous operation, it maintains stable performance, helping businesses reduce costs and improve profitability.

Fast Development Cycle

Laser engraving eliminates the need for traditional mold-making. With simple graphic or text processing on a computer, users can quickly create and engrave designs, saving significant time in production and development.

Eco-Friendly

Unlike conventional marking methods that require inks or chemical solvents, laser engraving is a clean process—no emissions, no noise, and no pollution. It fully aligns with modern environmental protection standards.

Versatile Applications

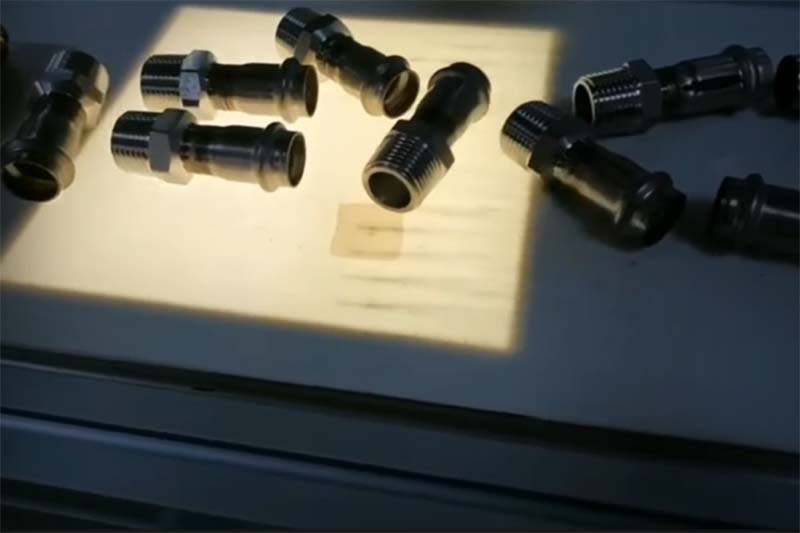

Beyond logo engraving, the handheld fiber laser engraver supports diverse marking needs, including QR codes, production dates, serial numbers, and more. Its versatility offers businesses broader application opportunities and greater market potential.

Limitation of Laser Engraver for Brand Logos

Power and Efficiency Constraints

Compared with high-power, high-speed desktop laser marking machines, handheld devices are relatively limited in power and processing efficiency. They are better suited for small to medium batches or personalized customization rather than large quantities, continuous production lines.

Dependence on Operator Stability

Since the device is manually operated, engraving results depend to some extent on the steadiness of the operator’s hand. Inconsistent handling may affect marking precision and uniformity.

Restricted Marking Size

Due to structural design and usage mode, handheld laser engravers are more suitable for small to medium-sized workpieces. For products requiring large-area marking, they may not fully meet the requirements.

Applications of Laser Engraving for Logos

The handheld laser marking machine is a versatile tool capable of handling a wide range of materials and marking needs. Whether on painted wood, tiles, metals, or other construction and decorative materials, it delivers sharp, precise engravings. The marking content can include logos, text, patterns, QR codes, and serial numbers—helping businesses and individuals achieve both personalization and professional branding with ease.

Home Decoration

With the growing demand for customization and unique design, home products increasingly emphasize individuality and brand recognition. By engraving company logos onto furniture, flooring, tiles, and other products, businesses can promote their brand in a creative way while adding value to their products. The handheld design ensures flexible, efficient operation, making it an ideal tool for customized home décor applications.

Building Materials Industry

Laser engraving on flooring, tiles, stone, and other building materials not only enhances decorative effects but also prevents counterfeiting. Adding brand logos or proprietary marks improves product recognition and protects intellectual property rights effectively.

Gift Customization

Engraving text, logos, or patterns on personalized gifts and souvenirs meets the rising demand for customization. Whether for corporate giveaways or personal keepsakes, laser engraving creates a premium, unique finish that enhances the commemorative and collectible value of the items.

Business Promotion

During exhibitions and brand promotions, handheld laser engravers can directly etch logos and patterns onto promotional items, decorative pieces, or even on-site building materials. This instant customization not only attracts attention but also strengthens brand presence and competitiveness in the market.

Market Advantages of Handheld Laser Engraving Machines

Outstanding Cost Efficiency

Although there is an initial investment, the Raycus handheld laser engraver delivers long-term savings through high processing efficiency and low maintenance requirements. By significantly reducing labor and time costs, it achieves an excellent return on investment.

Reliable Quality Assurance

With strict R&D and production quality control, the machine ensures stability and durability. Whether for long-term continuous operation or diverse application scenarios, it consistently maintains high precision and reliability, providing users with lasting satisfaction.

Comprehensive Customer Support

Putting customers first, Raycus offers complete service solutions—including pre-sales consultation, professional training, and attentive after-sales support—ensuring a worry-free experience throughout the entire usage process.

Future Market Potential

As laser technology continues to advance, handheld laser engravers for logo marking are expected to play an increasingly important role. With the rise of smart homes and the growing demand for personalized products, these machines are set to occupy a strong position in the future market, driving innovation and contributing to the development of the industry.

20W Handheld Laser Engraving Machine for Metal

The 20W portable handheld fiber laser engraver combines exceptional versatility with high precision, making it an ideal choice across multiple industries. Powered by advanced fiber laser technology, it delivers sharp and permanent markings on metals, plastics, and even reflective surfaces. Its compact and lightweight design makes it suitable not only for small studios but also for industrial production environments.

Key Advantages

Multi-Material Compatibility: Supports marking on metals, plastics, coatings, reflective materials, and more—covering a wide range of applications.

High Performance: Achieves marking speeds of up to 7,000 mm/s under various materials and process requirements, significantly boosting productivity.

Durable & Reliable: Core components have a lifespan of over 100,000 hours, ensuring low maintenance, stable performance, and long-term cost efficiency.

Portable & Flexible: The lightweight handheld design allows easy operation in confined spaces or complex scenarios.

Applications

The 20W handheld fiber laser engraver is well-suited for small and medium-sized processing businesses, home décor and building materials industries, personalized gift customization, as well as industrial part identification and traceability. It provides fine, damage-free marking on thermoplastics such as acrylic, ABS, and PVC—making it ideal for industrial labeling and brand identification.

Additionally, it performs reliably on wood, aluminum, stainless steel, brass, and coated metals, with wide applications in art creation, gift packaging, and industrial manufacturing. With fiber laser engraving, the lines are finer and more precise, enabling manufacturers to meet diverse demands—from personalized brand logo customization to innovative packaging design.

How to Choose a Handheld Laser Engraving Machine For Brand Logo?

Identify the Material Type

Determine whether you need to process metals or non-metals (such as acrylic, leather, etc.). Different materials require different laser engraving machine configurations.

Evaluate Speed within Budget

Within your budget, choose a model with faster engraving speed to improve production efficiency.

Select a Reputable Brand

Well-known brands usually offer better product quality and more reliable after-sales service.

Ease of Use

Choose a laser engraving machine that is simple to operate and easy to learn—especially important for beginners.

How to Use Portable Handheld Laser Marking Machine?

1) Material Preparation

Choose a suitable material to ensure crisp, durable logo results. Thoroughly clean the surface to remove dust, oil, and residues that could affect engraving quality. Keep wood dry and smooth; for metals, remove rust and grime so the laser can mark evenly.

2) Machine Setup & Safety

Place the workpiece on a stable surface and secure it firmly. Adjust the laser head height so the beam is correctly focused on the surface for sharp lines. Always wear certified laser safety goggles. Use the built-in shield/enclosure if provided, keep it closed during operation, and enable exhaust or ventilation to remove fumes. Confirm that all safety interlocks and protections are functioning.

3) Import & Align the Artwork

Open your engraving software and import the logo file. Resize, position, and rotate the design to match the target engraving area. Verify dimensions against the actual project and fine-tune as needed. If available, run a “frame/outline” preview to confirm alignment.

4) Set Laser Parameters

Choose appropriate power, speed, and resolution for the material. As a general guide, use 300–600 DPI to balance detail and efficiency (higher DPI = more detail but longer time). Start from the machine’s material presets, then fine-tune based on your tests.

5) Test Engraving

Before the final run, test on scrap of the same material. Engrave a small portion of the logo and check depth, contrast, and detail. Adjust parameters until you get the desired results.

6) Production Engraving

Once satisfied with the test, load the prepared workpiece. Re-check focus and alignment, then start the job. Monitor the process closely. Use simple fixtures (e.g., blocks, clamps, poster putty) to stabilize fragile or oddly shaped items. Working methodically helps achieve the best finish while reducing the risk of damage.

Quick Tips & Safety Notes (recommended):

Avoid unknown or chlorine-containing plastics (e.g., PVC) due to harmful fumes.

Keep a fire extinguisher nearby; never leave the laser unattended.

For highly reflective metals, consider surface prep (e.g., marking spray or temporary coating) to improve contrast and reduce back-reflection.

Maintain clean optics and consistent focus for repeatable quality.

Finally, whether you’re a startup small batches or a studio marker, the advantages are clear—fast processing, zero consumables, and long-lasting results. Especially when it comes to laser engraving logo on metal, our 20W portable handheld laser engraver delivers unmatched clarity, permanence, and efficiency. If you’re looking to strengthen your brand identity and stay ahead of the competition, investing in a high-performance laser engraver is the smartest choice in 2025.