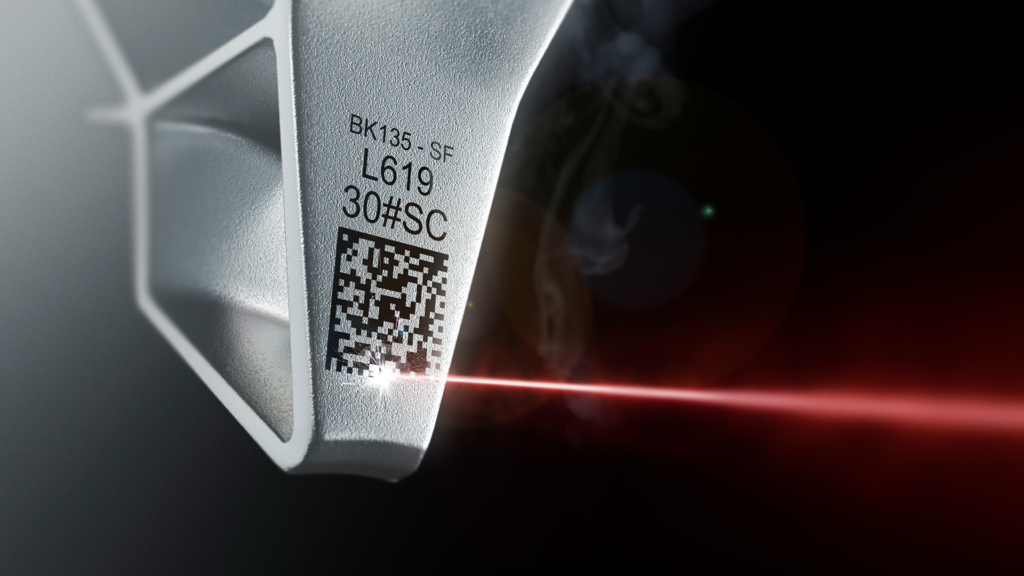

What is laser metal engraving machine? Metal laser engraving is a high-precision processing technique that uses a high-energy laser beam to etch surfaces, creating text, logos, images, QR codes, and more. By engraving fine grooves on the metal surface, it efficiently produces accurate and lasting marks. Due to its high precision and speed, this technology is widely used in various industries such as automotive parts, medical devices, jewelry, and mechanical components. In this post, you can learn about metal laser engraving and choose the best metal laser engraving machine for your needs.

Can You Laser Engrave Metal?

Yes, a laser can engrave metal, but it depends on the type of laser and the metal being engraved. Laser engraving is popular in industries such as jewelry, electronics, and automotive for its ability to create detailed designs, serial numbers, and logos.

Advantages of Laser Engraving Machine for Metal

Laser engraving on metal offers numerous advantages, making it highly popular in industrial processing.

High Precision: Laser technology enables incredibly fine engraving, with focused beams reaching micron-level precision. This allows for the creation of highly detailed patterns or text on metal surfaces.

Non-Contact Processing: Laser engraving heats and vaporizes part of the material surface using a focused laser beam, without applying mechanical force to the workpiece. This reduces the risk of damage caused by physical contact.

Fast Speed: Compared to traditional mechanical engraving methods, laser engraving is much faster, significantly improving production efficiency.

High Flexibility: Laser engraving systems can be easily controlled by computer programs, allowing for quick design changes without the need to replace tools. This is ideal for customization or small-batch production.

Wide Range of Applications: Laser technology can engrave a variety of metals, including stainless steel, aluminum, titanium, brass, and more. Laser parameters can also be adjusted to optimize engraving effects for different metal materials.

Superior Surface Quality: Since laser energy can be precisely controlled, it results in smooth, clear engravings, reducing the need for post-processing like polishing.

Reduced Material Waste: With its high precision and control, laser engraving minimizes material waste and allows for complex pattern designs in limited space.

Challenges of Laser Engraving Metal

First, metals, being highly conductive materials, have a lower capacity to absorb laser energy, requiring higher laser power for effective cutting. Additionally, metals dissipate heat quickly, making it difficult to concentrate laser energy for heating.

Here are some solutions to overcome these challenges:

- Using the Right Laser Type

CO₂ Lasers: While primarily used for non-metal materials, CO₂ lasers can also engrave metal surfaces in certain cases, especially by applying coatings or paints.

Fiber Lasers: These lasers are highly suitable for metal processing, as their wavelength is more easily absorbed by metals. Fiber lasers excel in cutting and engraving metals.

Surface Treatment

- Surface Treatment

Coating Method: A layer of easily engrave material (such as paint or ink) can be applied to the metal surface before engraving with the laser. After engraving, the coating can be removed to reveal the metal underneath.

Pre-treatment: Pre-treating the metal surface, such as with sandblasting, can improve laser absorption to some extent.

- Controlling Parameters

Adjusting Power and Speed: By adjusting the laser’s power and movement speed, you can optimize material absorption efficiency and reduce heat dissipation.

Pulse Mode: Using pulse mode instead of continuous mode helps control heat input and minimizes the heat-affected zone.

Assist Gas

- Using Assist Gas:

Gases such as oxygen or nitrogen can improve edge quality, reduce residue, and prevent oxidation.

What Metals Can You Laser Engrave?

Laser engraving affects different metals in various ways. Here are some common metals suitable for engraving:

Aluminum

Aluminum is a versatile metal that supports permanent, high-contrast marking on various types, such as pure aluminum, aluminum alloys, and coated aluminum. Both laser engraving and rotary engraving can create detailed and visually appealing markings that are heat-resistant and durable against environmental changes.

Brass

Brass is a softer metal commonly used for engraving. However, commercial-grade brass can be thicker and more challenging to engrave. For deeper engraving, brass sheets between 0.040 and 0.060 inches thick are recommended. Pigment is often added to non-engraved areas to enhance visual contrast.

Stainless Steel

Although the engraving process for stainless steel is more complex compared to other metals, its excellent moisture resistance, corrosion resistance, and durability make it an ideal choice. Since direct laser engraving may damage the surface’s protective layer, laser annealing is a common alternative in manufacturing.

Alloys

Alloys, known for their unique physical properties, are widely used in manufacturing and are common materials for engraving as well.

Precious Metals (Gold, Silver)

In the jewelry industry, laser engraving is frequently used on precious metals like gold and silver for fine detailing. It not only provides precise marking but also retains the original luster and texture of the metal.

Metal Laser Engraving vs. Laser Marking: What’s the Difference?

Metal laser engraving and laser marking are both techniques used to process metal surfaces with lasers, but they have distinct differences:

Laser Engraving

Laser engraving involves deeper material removal, creating visible grooves or raised areas on the metal surface. This technique is used to create intricate patterns, text, or logos, and due to its greater depth, the markings are highly durable and resistant to wear. Laser engraving is suitable for materials such as aluminum, brass, and stainless steel, and is ideal for applications requiring detailed and long-lasting markings, like serial numbers on industrial parts or decorative items.

Laser Marking

Laser marking, on the other hand, leaves a surface mark without penetrating deeply into the material. There are different methods for laser marking, such as:

Laser Annealing: Involves heating the metal surface to change its color.

Laser Etching or Ablation: Involves removing a coating to reveal a different colored layer underneath.

Laser marking provides high resolution and fine detail, making it ideal for applications requiring high-contrast markings, such as production dates, barcodes, or QR codes.

In summary, laser engraving creates deeper marks that are more suited for long-term exposure and durability, while laser marking focuses on high-contrast and high-precision markings, typically for information labeling purposes. Both methods can be adjusted to achieve the best results based on the specific application.

How to Achieve Color Laser Marking On Metal?

Laser engraving color on metal involves several techniques to achieve vibrant and precise results:

- Thermal Effects: By controlling laser power and scanning speed, different oxide layer thicknesses can be produced on the metal surface, leading to changes in its reflective spectrum and displaying various colors.

- Oxide Formation: For certain metals, such as titanium and stainless steel, the thermal effects of the laser can create a thin oxide film on the surface. Controlling the thickness of this oxide layer can show different colors through interference effects. This usually requires very precise adjustments of laser parameters.

- Multiple Scanning Processes: By scanning multiple times and adjusting different laser parameters, such as frequency, power, and speed, specific colored patterns can be created on the metal surface.

- High-Speed Lasers: Using high-speed laser marking machines, like picosecond or femtosecond lasers, can create nanostructures on the material. These structures interact with light to produce color effects.

- Chemical Coloring Method: Sometimes, laser processing is combined with subsequent chemical treatments. After laser marking, the metal can be immediately immersed in specific chemical solutions to create color effects.

Not all metals can support color laser marking. If you have specific requirements, please contact us with your marking materials and production processes, and we will customize a laser marking solution for your production needs.

How to Choose a Metal Laser Engraving Machine?

Choosing the right laser engraving machine requires consideration of several factors:

Engraving Material: Different materials require different types of laser engraving machines. For example, if you need to work with stainless steel, opt for a model with high laser power and a fiber laser source.

Engraving Depth: Select a laser with the appropriate power based on your required engraving depth.

Engraving Precision: If your work involves highly detailed patterns or text, choose a machine with high precision capabilities.

Work Area Size: Determine the maximum size of the objects you will engrave, and select a machine with a sufficient worktable area.

Automation Level: Some advanced laser engraving machines feature automated material loading and unloading or can be integrated with robotic arms, which enhances production efficiency.

Price and Service: Choose a brand that offers a balance between affordability and comprehensive after-sales service.

Fiber laser engraving machines can achieve permanent markings on a wide range of materials, including carbon steel, stainless steel, galvanized steel, aluminum, brass, copper, silver, gold, titanium, iron, and their alloys. These machines can handle tasks like printing, engraving, and etching on 2D or 3D surfaces, making them suitable for engraving text, numbers, symbols, logos, and images.

At high power settings, the device can even create embossed effects or deep engravings on metal surfaces.

With an additional rotary attachment, it easily handles the surface processing of circular, cup-shaped, or cylindrical objects. When combined with a conveyor belt, the system is ideal for continuous dynamic marking in production lines. Moreover, using a MOPA laser source allows the system to produce color effects on metals like stainless steel, chrome, and titanium.

Finally:

Laser engraving is an ideal process for high-quality metal product finishing and brand marking. More and more manufacturers are turning to metal laser engraving to produce customized parts. If you’re looking to make your products stand out, it’s time to consider this process. Now, you’re equipped to answer the question, “can you laser engrave metal?” Share your metal engraving needs in the comment below, and Dapeng Laser is ready to offer you a one-stop solution for part processing, including marking, engraving, etching and carving. Contact us today to get technical support!