Large-format laser marking machines feature a large processing area and high processing efficiency. They are commonly used for high-precision marking on large surfaces, such as in the production of advertising signs, metal products, building materials, medical devices, and automotive parts. Large format laser engraving enable permanent and fine marking on large surfaces, curved objects, and intricate 3D designs, making them ideal for diverse manufacturing applications.

How does Large Format Laser Marking Work?

To achieve large-format laser marking, the key lies in the control and focusing of the laser beam. Traditional laser marking machines often face issues such as defocused beams and blurry markings when handling large surfaces. To address this, large-format laser marking machines typically utilize dynamic focusing technology. This technology adjusts the focal length of the laser beam, ensuring that it remains sharply focused across the entire marking area, resulting in clear and precise markings.

Another critical factor in large-format laser marking is marking speed and power. Since large surfaces require longer marking durations, marking speed is one of the most crucial considerations in industrial applications.

To enhance marking efficiency, large-format laser marking machines often incorporate high-power lasers or multiple laser sources. By optimizing laser parameters—such as power, frequency, and pulse width—the marking process can be accelerated. This design not only increases energy density and improves material interaction but also reduces marking time per session, enabling high-efficiency production.

Additionally, galvo scanning systems and high-speed motion platforms further optimize the marking process across large areas, ensuring both precision and speed in industrial applications.

Features

- Large Processing Area: Suitable for large-format marking applications.

- High Marking Precision: The fine laser beam enables small marking areas, ensuring high precision.

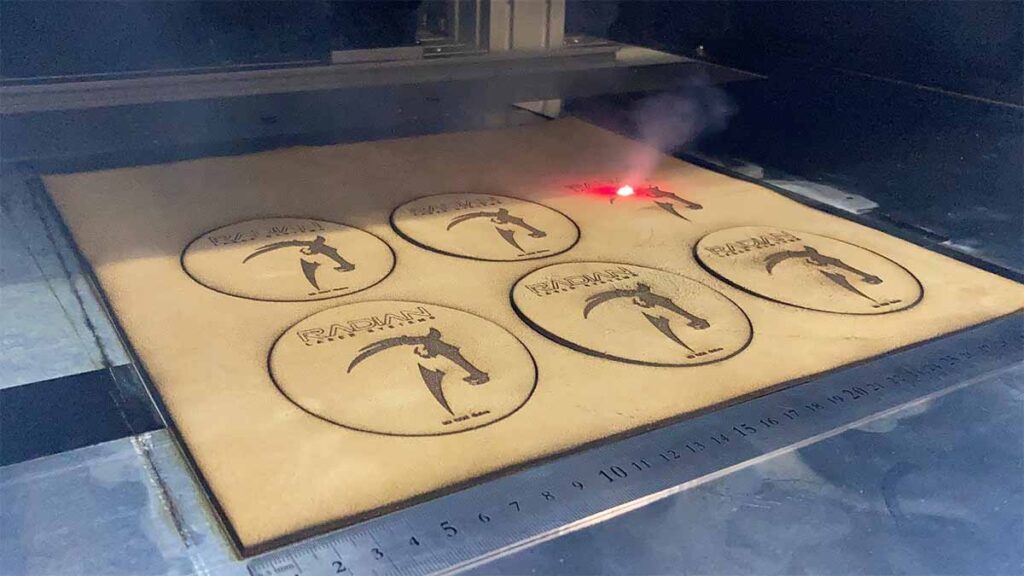

- High Efficiency: Large-format laser engraving machines typically use multiple laser heads or conveyor-based designs, allowing simultaneous processing of multiple objects and significantly improving efficiency.

- High Level of Automation: Some machines are equipped with automatic feeding, collection, and sorting systems, enabling automated material handling and further enhancing production efficiency.

- Superior Marking Quality: Laser marking machines can quickly and clearly engrave text, patterns, logos, and more on various objects, ensuring high clarity and aesthetic appeal.

- Wide Application Range: In addition to marking metals and certain non-metal materials such as advertising sign letters, it can also process wood, acrylic, plastic, and other materials.

- Excellent Stability: High-end laser sources ensure consistent processing quality and long service life.

Applications of Large Format Laser Marking For Metal?

- Multi-Material Marking: Capable of high-precision marking on various materials, including plastic, metal, wood, glass, silicon wafers, and ceramics, meeting diverse industrial and commercial needs.

- Product Information Marking: Widely used for marking production dates, expiration dates, batch numbers, and specifications to ensure product traceability and compliance.

- Anti-Counterfeiting & Traceability: Supports anti-counterfeiting markings, integrating QR codes, barcodes, and micro-text technology to enhance product security and prevent counterfeit products from entering the market.

- Brand Customization: Engraves brand logos, trademarks, and custom patterns, enhancing brand identity and product value.

- Production Process Identification: Marks production-related information such as serial numbers, process parameters, and tracking codes to facilitate internal management and product traceability.

- Large-Scale Marking: Supports large-format marking to accommodate big products such as billboards, packaging materials, and mechanical components.

- High-Resolution Printing: Offers high-precision and high-resolution marking, ensuring sharp, intricate text, patterns, and complex graphics for detailed processing requirements.

- Sequential Number Marking: Supports variable data marking, including serial numbers and batch numbers, enabling automated management and improved production efficiency.

- Online Fly Marking: Can be integrated into production lines for on-the-fly marking, working seamlessly with robotic arms and other automation equipment to enhance production automation.

With its high efficiency, precision, eco-friendliness, and cost-effectiveness, large-format laser marking systems are widely used in industries such as food packaging, electronics, automotive manufacturing, medical devices, advertising signage, and hardware tools.

Several Types of Large Format Laser Engraving Machine

Large Format Field Mirror Laser Marking

This method achieves large-format laser marking by replacing the field mirror with one of a larger range, which is the most common approach. The available lens ranges typically vary from 100×100 mm ~ 600×600 mm. It is cost-effective and simple to operate, but the marking energy diminishes as the format increases, and slight deformation may occur at the edges.

XY Motorized Platform Stitching Laser Marking

This technique utilizes an XY motorized platform to gradually move the workpiece for segmented marking, enabling virtually unlimited large-format processing. It produces fine markings without the line thickening that might occur with larger lenses. However, stitching errors or visible seams may appear, and the method demands high-precision platforms, control cards, and sophisticated graphics processing, which results in higher costs.

Dynamic Large Format Laser Marking (3D Laser Marking)

By dynamically adjusting the pre-focusing lens, this method ensures a consistent beam thickness across the entire marking area, thus avoiding edge deformation and achieving fine processing. While it offers high precision, it requires specialized galvanometers, control cards, and software support, making it a higher-cost solution.

Large Format Seamless Platform Laser Marking

In this approach, an XY platform moves synchronously during the marking process, ensuring that the entire large-format area is marked without any seams. It is fast and produces fine lines with moderate laser power requirements. However, due to its technological complexity, this method is currently less used.

Large Size 3D Dynamic CO₂ Laser Marking Machine

The large format 3D dynamic CO₂ laser marking machine is capable of efficiently processing large workpieces with fast marking speed and high productivity, making it ideally suited for mass production. Its high-precision 3D positioning technology, combined with a high-speed focusing and scanning system, endows the laser beam with features such as a base pattern, short pulse, high peak power, and high repetition frequency, delivering exceptional marking results to users.

It employs a fully automatic, left-and-right moving work platform that synchronizes laser processing, loading, and unloading, significantly reducing manual operations and enhancing production efficiency. Additionally, the laser marking system supports electric lifting to meet various processing needs, ensuring flexibility and precision. The overall design adheres to international safety standards and features a fully enclosed laser protection scheme to guarantee operational safety.

Low Maintenance Cost

The built-in CO2 laser source requires virtually no maintenance and is highly reliable. The energy consumption of the laser marking machine is very low, with no need for consumables, spare parts, or maintenance expenses.

High-Speed Laser Marking

The portable laser marking machine is specifically designed for marking a large number of small and medium-sized parts. It can mark items such as pens, electronic housings, or data boards in just a few seconds.

Simple Operation

Ezcad software supports almost all common file formats. There is no need to understand any programming languages; simply set a few parameters and start marking.

Electric Displacement Work Platform

The large-format, electric, split marking system is enhanced with additional columns and an electric displacement work platform, enabling it to meet the marking requirements of larger objects.

3D Dynamic Focus laser marking machines are suitable for most non-metallic materials, including leather, fabric, wood, bamboo, paper, and organic materials. They can perform precise marking, engraving, hollowing, perforation, and cutting processes.

CO₂ laser marking machines are widely used in industries such as clothes making, pharmaceutical packaging, beverage packaging, fabric cutting, rubber products, nameplates, crafts, electronic components and leather. They are ideal for high volume production for instant laser marking of boxes, engraving and cutting of paper products and coding of metal nameplates and housings.

Advantages:

High Precision & Speed – Provides fast marking speeds with adjustable engraving depth, offering flexibility for various applications.

High Laser Power – Suitable for engraving and cutting a wide range of non-metallic materials. Optional fiber or UV laser sources can be used for marking metal materials and fragile materials like glass.

No Consumables & Low Processing Costs – No consumables required, with a laser lifespan of 20,000 to 30,000 hours, reducing overall operational costs.

Clear & Durable Marking – Produces sharp, wear-resistant markings with high engraving and cutting efficiency, ensuring energy conservation and environmental friendliness.

Supports Multiple File Formats – Compatible with PLT, PCX, DXF, BMP, JPEG formats, and supports SHX and TTF fonts directly.

Automatic Marking Features – Supports automatic encoding, printing serial numbers, batch numbers, dates, barcodes, QR codes, and automatic number skipping.

Powerful Graphics Drawing & Editing – Can directly mark color images and also convert color images to grayscale for marking.

| Laser Wavelength | 10.6nm |

| Beam Quality | M2<1.5-1.8 |

| Laser Q-frequency | 1KHZ-50KHZ |

| Optional engraving range | 100×100mm 300×300mm 600×600mm 1200×1200mm |

| Minimum line width | 0.03mm |

| Minimum character | 0.3mm |

| Repeatability | ±0.001mm |

| Engraving depth | ≤1-5mm |

| Engraving speed | ≤7000mm/s |

| Power of the whole machine | ≤0.8KW-3.0kw |

| Cooling mode | Air Cooled / Water Cooled Optional |

| Laser power | 100W-320W |

Curved Surface Laser Engraving Machine

The curved surface laser engraving machine (also known as the 3d dynamic focusing laser marking machine) combines 3D dynamic galvanometer technology with 3D modeling software, enabling zoom engraving. This allows for high-precision, one-step marking on curved surfaces and products with height variations, meeting the demands of intricate marking on uneven or complex geometries.

- Curved Surfaces and Height Variations

Capable of precise marking and engraving on irregular concave and convex surfaces or stepped structures. Utilizes a high-precision 3D scanning system that detects the surface geometry of the object in real-time and adapts the marking accordingly.

- High Precision and Efficiency

Fast marking speeds with high precision in a single pass, improving production efficiency. Ideal for mass production, enhancing both processing quality and consistency.

- Premium Marking Quality

Employs advanced laser technology to achieve clear, durable markings such as text, patterns, and barcodes.Ensures high-quality engraving results even on uneven surfaces.

- Wide Material Compatibility

Suitable for a variety of materials, including metal, plastic, ceramic, and more, fulfilling the marking needs for different materials.

Large Format UV Laser Marking Machine

The large format uv laser marker is designed for high-precision marking on a wide range of materials, including glass, acrylic, plastic, film, ceramics, and coated metals. Utilizing ultraviolet (UV) laser technology, it ensures minimal heat impact during the marking process, making it ideal for delicate or heat-sensitive materials. This machine offers exceptional detail and high-quality engraving, providing sharp, clear marks that are resistant to wear and fading. With its large marking area, it allows for efficient processing of large and fine products.

Large Format Laser Marking Machine Price

The price of a large format laser marking machine can vary significantly depending on factors such as:

Laser type (CO2, fiber, UV, etc.)

Power and laser source (higher power options typically cost more)

Machine size and marking area (larger marking areas tend to be more expensive)

Brand and manufacturer

Additional features (e.g., automated feeding systems, advanced software, or precision components)

On average, large format laser marking machines can range from $3,000~$10,000 or more, depending on the specifications.

Please feel free to request quotes directly with us to get a more accurate price based on your specific needs and requirements.

In conclusion, large size laser marking machines are revolutionizing the way industries approach engraving and marking large or complex surfaces. With their precision, versatility, and ability to handle larger workpieces, they are a valuable asset for various manufacturing sectors. Whether you are looking for a large format 3D laser marking machine or a curved surface laser marking machine, investing in the right equipment can significantly enhance your production efficiency and quality. Reach out to us today to find the perfect large-format laser marking machine tailored to your needs.