Why Use Picosecond and Femtosecond Lasers for Marking & Cutting?

Picosecond (10^-12 second) and femtosecond (10^-15 second) lasers, with their ultra-short pulse durations and minimal heat impact, achieve micron-level precision, making them ideal for high-precision marking and cutting of plastic, glass, and delicate substrates. Even on heat-sensitive or ultra-thin materials, they prevent burning or yellowing. These ultrafast lasers are suitable for industrial and precision applications, including OLED and LCD manufacturing.

We provide customized femtosecond and picosecond laser marking machines for 24/7 industrial needs. They excel in marking, drilling, and cutting materials like sapphire, plastic, glass, metals, brittle and transparent substrates, thin-film and FPC PCB boards.

Aluminum & Stainless Steel Black Marking

Picosecond laser marking machines create high-contrast black and color markings on aluminum and stainless steel with exceptional precision. Their ultrafast pulses prevent thermal damage, resulting in smooth, burr-free, and microcrack-free surfaces. Ideal for durable, high-quality marking on reflective metals.

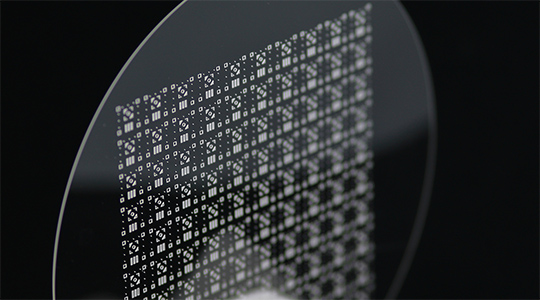

Glass and Brittle Material Processing

Picosecond lasers excel in marking and cutting plastic, glass, and brittle materials by creating clean cuts and microfeatures with minimal damage or cracking. The ultrashort pulse laser offers high power density, allowing for precise structuring and engraving without burning or yellowing the edges.

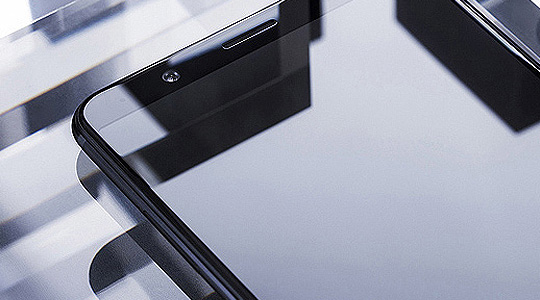

LCD & LED Cutting

Picosecond lasers enable precise cutting and drilling of LCD and LED components, ensuring smooth edges and micro-scale accuracy. Their ultrafast pulses minimize thermal damage, preserving the integrity of delicate display substrates.

Infrared Picosecond Laser Marking Machine

The Infrared Picosecond Laser Marking Machine excels in high-speed and high-precision marking & engraving, delivering sharp, detailed markings on a variety of materials, including glass and plastics. Its ultrafast pulses minimize thermal effects, ensuring minimal material deformation and achieving flawless surface finishes. It excels in brittle transparent material processing, metal micromachining, and flexible PCB micromachining, making it an ideal solution for industries requiring exceptional precision and durability.

UV Picosecond Laser Marking Engraving & Cutting Machine

The UV Picosecond Laser Marking Machine specializes in ultra-precise, non-thermal processing for semiconductors, PCBs, FCBs, and OLED thin films. Its shorter wavelength enables micro-scale accuracy, making it perfect for delicate, heat-sensitive materials. With near-zero heat-affected zones, it ensures fine detail, high contrast, and reliability, meeting the strict industrial requirements.

Applications of Ultrafast Laser Marking Machines include:

- Precision micromachining

- Black marking of stainless steel or aluminum

- Stainless steel color marking

- Surface micro-structuring and texturing

- Cutting of thin films and ultra-thin materials

- Battery and thin metal foil cutting

- Sapphire wafer cutting

- Cutting of LCD and LED panel displays

- Marking & cutting of precise metals and polymers

- Engraving & cutting of plastic or glass

- Micromachining of ceramics