Laser welding machines have become an integral part of the manufacturing industry and their market size continues to expand. Their sales continue to grow thanks to their efficient and precise welding capabilities, as well as their ability to improve productivity and quality. Specific uses for laser welding machines include welding of complex shapes and materials, fabrication of high-density connections, and fine control of the welding process. As a global manufacturing center, China has a number of laser welding machine manufacturers with leading technology and excellent quality. These companies not only lead the domestic market but have also gained wide recognition in international markets. This article will list the top 10 laser welding machine manufacturers in China.

Why is the Laser Welding Machines Market Growing?

- Technological Advancements: Continuous advancements in laser technology have significantly improved the performance and stability of laser welding machines, driving an increase in market demand.

- Demand for High-Efficiency and High-Quality Production: The manufacturing industry’s growing demand for efficient and high-quality production makes laser welding machines a preferred choice for manufacturers, as they enhance both productivity and product quality.

- Cost Advantages: Laser welding systems offer notable cost advantages, especially in large-scale production, by reducing labor costs and improving overall production efficiency.

The Top Laser Welding Machine Manufacturers 2025

Han’s Laser

Han’s Laser has become a pioneer in China’s laser industry, excelling in the research, development, and accumulation of patents in laser technology. This is mainly reflected in their continuous R&D investment and technological breakthroughs. The company has mastered several core laser technologies and accumulated a large number of patents, covering all aspects of laser application systems. These patents provide Han’s Laser with strong technical barriers and a competitive market advantage.

HGTECH

HGTECH is a trailblazer in the industrialization of university research achievements in China. Through years of technological innovation and accumulation, HGTECH has developed a smart manufacturing equipment business centered on laser processing technology. This supports a wide range of industries, including mechanical manufacturing, railway, the automotive industry, consumer electronics, steel metallurgy and heavy industries.

DPLASER

Shenzhen Dapeng Laser Technology Co., Ltd. has established long-term technical cooperation and R&D partnerships with internationally renowned laser manufacturers, mastering a number of core technologies. The company offers a wide range of laser equipment, including laser marking machines, laser cutting machines, laser cleaning machines and laser welding machines, which are widely used across various industries. By adhering to a philosophy of high quality and service, Dapeng Laser has earned the trust and praise of its customers and commands a significant share of the domestic market. As a national high-tech enterprise integrating R&D, production, sales, and service, DP Laser’s products are distinguished by their excellent flexibility, intelligence, high quality, and cost-effectiveness, meeting the diverse needs of the market.

DPLaser Laser Welding Machine Factory:

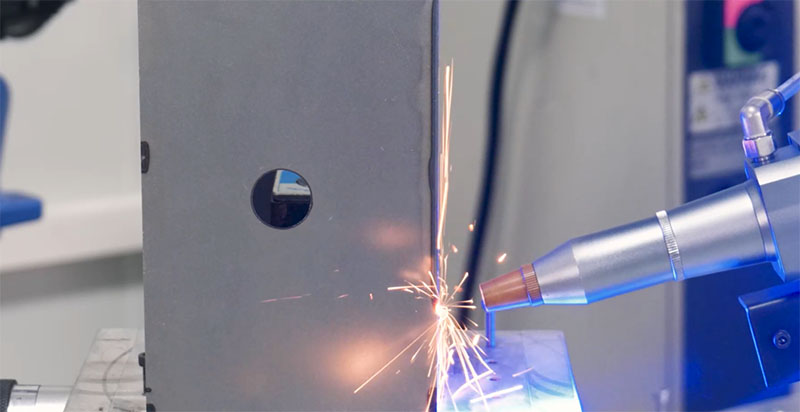

DP Laser offers a wide range of high-performance laser welding solutions, with handheld fiber laser welding machines in particular accounting for the majority of the market share. With its cost-effective and extremely high machine performance it has successfully consolidated its position in the laser welding industry.

High precision: advanced laser technology is used to ensure welding precision and quality.

Versatility: the product is suitable for a wide range of materials and processes, such as metal welding and plastic welding.

Easy to operate: the equipment is easy to operate with friendly interface, which reduces the technical requirements for operators.

High efficiency and energy saving: fast welding speed and low energy consumption improve productivity and reduce costs.

Customized service: provide personalized solutions according to customers’ needs.

Haiwei Laser

Haiwei Laser specializes in robotic laser welding machines, handheld laser welding machines, multi-axis automatic laser welding machines, and lithium battery PACK welding, among other products. With 17 years of professional experience in the R&D of laser welding systems and industry applications, Haiwei Laser provides specialized, high-precision automated laser welding solutions.

Hymson

Founded in 2008, Hymson focuses on the laser and automation sectors, offering products such as lithium battery automation systems, air-cooled ultraviolet laser equipment, and large-scale automated production lines. These products are widely used in new energy, 3C electronics, and automotive industries. Hymson has accumulated extensive experience and technical expertise in laser welding technology, providing high-quality solutions for its customers.

GWEIKE

GWEIKE Laser offers a rich and specialized product line that spans from small and medium power to high power laser processing applications. The company excels in laser cutting, laser welding, and full-scenario intelligent solutions. GWEIKE’s core competency lies in independent R&D, with continuous breakthroughs in laser power control technology, beam quality optimization, and dynamic focusing systems.

Chutian Laser

Chutian Laser is a professional laser equipment manufacturer with large-scale production capabilities, an extensive product line, and a broad market presence. Its equipment is widely used in industrial manufacturing, healthcare, and precision processing, earning a global reputation. Chutian Laser has established advanced production bases in cities such as Beijing, Wuhan, Suzhou, and Shanghai, dedicated to providing comprehensive and efficient laser technology solutions to customers worldwide.

Senfeng Laser

Senfeng Laser is focused on building a complete business chain that covers cutting, bending, welding, cladding, and automation. The company offers a diverse product portfolio, including laser cutting machines, laser welding systems, laser cladding devices, laser cleaning tools, and flexible laser processing production lines. By meeting the global demand for various automated equipment, Senfeng Laser continuously drives advancements in industry productivity and automation levels.

Baison Laser

Baison Laser is a high-tech enterprise integrating laser technology, precision machinery, CNC technology, software development, and modern management. The company specializes in the R&D, production, and sales of medium and high-power laser equipment, offering a range of high-performance products, including laser cutting machines, laser tube cutting machines, coil laser cutting machines, and fiber metal laser cutting machines.

XT LASER

XT LASER is a high-tech enterprise specializing in the field of laser intelligent manufacturing, offering high-quality products, services, and system solutions. The company’s main products include laser cutting machines and laser welding machines. XT LASER’s core advantages lie in its cost-effective products and excellent after-sales service, which have earned it widespread recognition from customers both domestically and internationally.

Key Considerations When Choosing a Laser Welding Machine

When choosing the best laser welding machine manufacturers, it’s important not to focus on the brand of the manufacturer. Instead, attention should be given to the key components of the laser equipment and their respective brands, as high-quality parts are essential for ensuring good production efficiency and product quality. This means that when selecting a laser welding machine, it’s crucial to carefully consider the performance of key components such as the laser source, optical elements, and control systems to ensure the overall stability and reliability of the equipment.

Laser Source

The laser source is the core component of a laser welding machine, determining beam quality, energy density, and processing efficiency. In the laser source market, brands like Raycus and Maxphotonics are highly regarded. When selecting the appropriate laser source, factors such as power output, wavelength, beam quality, pulse characteristics, and cost-effectiveness should be considered to ensure optimal welding quality and production efficiency.

Welding Control System

The control system precisely manages key laser welding parameters, including power adjustment, pulse frequency, welding path, and motion control. Advanced control systems are typically equipped with intelligent software that supports preset parameter recall, real-time monitoring, and feedback adjustment, enhancing welding accuracy and consistency.

Laser Welding Head

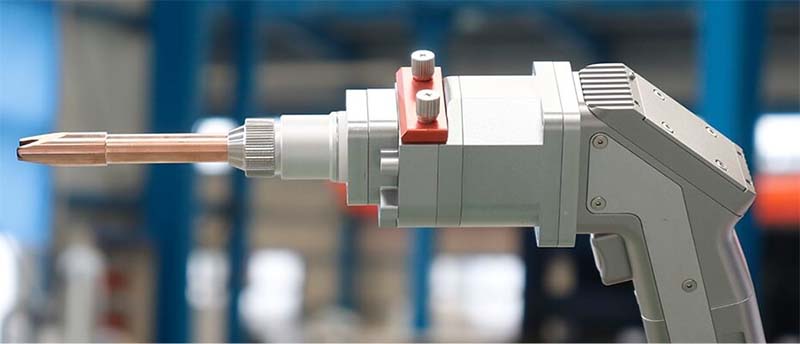

The laser welding head enables various welding techniques such as spot welding, butt welding, overlap welding, and sealing welding for thin-walled materials and precision parts. It features an aiming combination design, incorporating visual CCD acquisition technology and an integrated infrared sensor to ensure precise positioning of the weld and high-precision control throughout the welding process.

Focusing Lens

The focusing lens within the welding head determines the focal point size and shape of the laser beam, which is critical for welding precision and weld seam quality. High-quality focusing lenses can reduce weld defects and improve welding consistency.

Motion Axis

With high positioning accuracy and responsive movement, the motion axis features an anti-vibration design, allowing the entire welding process to be conducted without manually moving the product, instead utilizing automated movement for welding.

Weld Monitoring

High-definition CCD displays enable operators to observe the welding process closely, ensuring aesthetic weld points. The industrial control computer, equipped with a control system and specialized welding software, guarantees stable parameter settings and supports multi-level waveform adjustment, ensuring consistent and high-quality welding results.

Machine Structure

Rigidity and Stability: The rigidity and stability of the machine structure directly affect welding precision. A heavy-duty machine structure can reduce vibration and maintain stability during high-power welding processes.

Why Choose China Laser Welding Machine Manufacturer?

Cost-Effectiveness

China’s relatively low manufacturing costs make laser welding machines from this region more competitively priced compared to products from developed countries. This allows customers to obtain high-performance equipment at a lower cost.

Technological Advancement

Chinese manufacturers are also focused on research and development, continually introducing innovative technologies and solutions. Many manufacturers have developed products that surpass those of international brands.

Wide Range of Options

The Chinese market offers a diverse selection of laser welding machines with a full range of specifications, meeting the needs of different industries and applications. Whether for small businesses or large industrial production lines, suitable equipment can be found.

Customization Capability

Many Chinese manufacturers provide customization services, allowing them to adjust product design and features according to specific customer requirements. This flexibility ensures that the machines are more tailored to the unique demands of practical applications.

Supply Chain Advantage

China has a complete industrial chain, from raw material supply to component processing, which is highly efficient and convenient. This helps to improve production efficiency and reduce manufacturing costs. Additionally, a strong logistics network ensures timely delivery and service support.

Market Adaptability

Chinese manufacturers often have a better understanding of local market demands and can quickly respond to market changes and technological trends. For customers who need to rapidly iterate their products, this is a significant advantage.

After-Sales Service and Support

An increasing number of Chinese manufacturers are placing more emphasis on building robust after-sales service systems, offering timely technical support and maintenance services. Many large Chinese manufacturers have also established distribution and service networks worldwide, providing convenience for overseas customers. Han’s Laser, HGTECH, Dapeng Laser, and others have a high reputation and market share both domestically and internationally, making them trustworthy brands.

Why Choose DPLASER as Your Laser Welder Manufacturer?

DPLASER is a professional laser equipment manufacturer that has successfully obtained CE, FDA, and ISO9001 certifications. With dozens of service centers worldwide, Dapeng Laser provides localized services and technical support to global customers, ensuring exceptional quality and service.

We have a strong laser technology R&D team that develops durable laser solutions meeting international quality standards. Our factory ensures that we can offer competitive market prices.

Our powerful laser equipment manufacturing team can customize machines according to your project needs to better support your production and manufacturing. In addition, our fiber laser experts provide 24/7 support, including project evaluation and free sample testing.

Which laser welding machine brand is the best? Choosing the right brand and equipment will help enhance production efficiency and welding quality. Whether you are in the jewelry, packaging, machinery manufacturing, metal fabrication, household appliances, electronics, or other industries, these laser welder manufacturers in 2025 can meet your needs.