In 2025, the best laser marking machines offer small businesses and manufacturers more efficient and precise solutions for engraving and marking various materials. From high-speed fiber laser engravers for metals to CO₂ laser machines for wood and acrylic, and advanced infrared picosecond or UV femtosecond lasers for ultra-fine marking, there are numerous options to suit different industrial needs.

The laser engraving machine utilizes laser technology for engraving, cutting, and marking processes. It employs a laser beam for high-precision machining on various materials, including wood, plastic, leather, paper, fabric, rubber, acrylic, glass, ceramics, and more. Common laser sources include fiber lasers, CO₂ lasers, and UV lasers, offering high precision, speed, efficiency, low noise, and energy savings. These machines are widely used in the production of jewelry, handicrafts, models, signage, gifts, decorations, souvenirs, and electronic products. This article will introduce the best laser cutter for small businesses, helping business owners choose the ideal machine for their needs.

Trotec Laser is a globally renowned company from Austria, specializing in the research, development, and manufacturing of high-end laser cutting, engraving, and marking systems. Known for its exceptional product quality, long-lasting durability, and low maintenance costs, Trotec has earned a strong reputation worldwide.

Its laser equipment is widely used across various materials, including metal, plastic, wood, leather, and textiles, offering comprehensive solutions for both industrial manufacturing and creative design. Whether for large production or intricate handcrafted creations, Trotec’s machines meet the highest standards, making it a preferred brand in the industry.

Dapeng Laser, recognized as a top laser marking brand for metal in 2025, is an innovative company specializing in laser cutting and engraving machine. It is renowned for its highly customized solutions, dedicated to providing personalized laser equipment that caters to the diverse needs of various industries and applications. Whether for industrial manufacturing or small business applications, Dapeng Laser designs top laser marking machine for metal tailored to specific customer requirements.

The company’s core strengths lie in its expert laser engineering team and exceptional customization capabilities. From equipment size and power configurations to functional modules, customers can select options based on their production needs. This flexible service model makes Dapeng Laser an ideal partner for small and medium-sized enterprises, creative studios, and large manufacturing companies. By offering efficient, reliable, and customized solutions, Dapeng Laser helps businesses enhance production efficiency, reduce costs, and achieve superior processing quality.

Beamer Laser Systems

Beamer Laser Systems is a leading innovator in the U.S. laser technology industry, specializing in advanced laser marking, cutting, welding, and engraving solutions. Its state-of-the-art laser systems deliver deep engraving, high-speed marking, and exceptional contrast on materials like metal and plastic. Beamer’s technology not only enhances production efficiency but also ensures high precision and consistency, making it widely used in high-demand industries such as automotive, electronics, and medical device manufacturing.

OMTech is known for its affordable and user-friendly laser marking solutions, making it an ideal choice for small businesses, startups, and professionals on a budget. Its fiber laser marking machines offer excellent marking quality at an accessible price, earning popularity among users. With a simple and intuitive system design, even beginners can easily operate OMTech machines, making them a favorite among hobbyists, small workshops, and manufacturers. OMTech strikes the perfect balance between cost-effectiveness and performance, providing reliable laser marking solutions for a wide range of users.

Epilog Laser

Epilog Laser is a U.S.-based company with over 30 years of experience in developing and manufacturing laser cutting and engraving systems. Its CO₂ laser systems are renowned for their high speed and precision, enabling intricate engraving on various materials, including wood, acrylic, plastic, glass, and coated metals. Epilog’s machines are widely used in both commercial and artistic applications, catering to large-scale production as well as personalized customization. With cutting-edge technology and reliable performance, Epilog Laser stands as a global leader in the laser industry.

Keyence Inc is a global leader in industrial automation and laser marking, providing cutting-edge fiber laser systems, barcode readers, and sensor solutions for high-tech industries. Its product range includes AI-powered laser marking, vision-based inspection, and factory automation technologies that help businesses enhance production efficiency and product quality. Known for its innovation and comprehensive customer support, Keyence has earned worldwide recognition and trust in the industrial sector.

XToolspecializes in affordable and innovative laser cutting and engraving solutions, designed for DIY enthusiasts, artisans, and small businesses. Its products are highly versatile, easy to use, and cost-effective, making them ideal for home workshops, creative studios, and educational institutions. XToolmachines offer simple operation with extensive creative possibilities, allowing users to bring their ideas to life effortlessly. Whether for personal projects or small-scale commercial applications, XToolprovides reliable laser technology to support a wide range of creative needs.

Top Laser Marking Machine in 2025

100W Fiber Laser Engraving Machine

The 100W fiber laser engraving machine is a high-performance device designed specifically for the precise engraving, marking, and cutting of metal materials. It features advanced fiber laser technology, renowned for its high power, speed, and exceptional durability. Recognized as one of the top laser marking in 2025 for metal, this machine meets the demands of industrial manufacturing, jewelry processing, custom gift creation, and more.

High Power Output: The machine delivers 100W of power, enabling it to process a wide range of metals, including stainless steel, aluminum, and brass, achieving intricate details and complex designs.

Precision: The fiber laser provides exceptional precision for fine, accurate engraving. The results have smooth, clean edges without any burrs or roughness.

Speed: This machine offers high-speed engraving, making it suitable for both small home studios and large-scale industrial production projects.

Durability: With a long service life and minimal maintenance, the fiber laser is a highly durable solution.

Auto-Focus: Automatically adjusts to ensure the best focal point for each engraving, improving result quality and consistency.

Application:

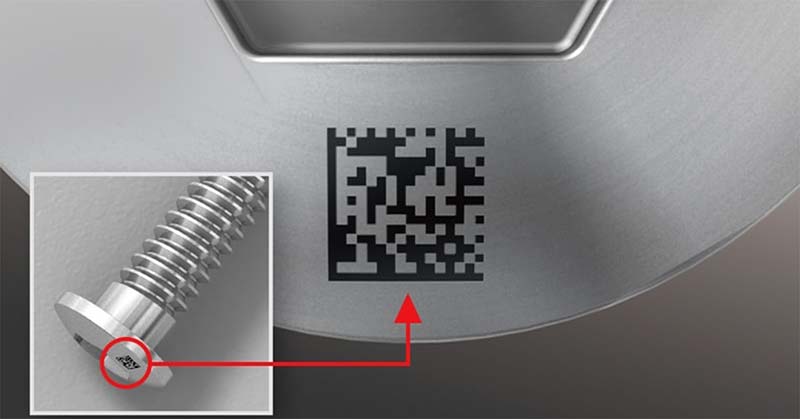

Industrial Marking: Ideal for engraving serial numbers, barcodes, brand logos, and more on metal parts, ensuring product traceability and brand recognition.

Jewelry Engraving: Capable of fine engraving of patterns and text on rings, bracelets, pendants, and other jewelry pieces, fulfilling high-end custom design needs.

Custom Gifts: Provides personalized engraving for metal items such as keychains, pens, trophies, and other keepsakes, creating unique and memorable gifts.

Mold Processing: Suitable for precise engraving and marking on metal molds, enhancing the accuracy and efficiency of industrial manufacturing.

Packaging Manufacturing: It is perfect for marking logos, product information, barcodes, and batch numbers on materials like metal, plastic, and cardboard. Its high precision and speed, combined with assembly line cooperation, ensure clear, durable markings, making it ideal for both high-volume production and custom packaging.

This fiber laser marking &engraving machine offers a powerful, precise, and versatile solution that can deliver high-quality results for a wide range of applications, from industrial manufacturing to personal customizations.

CO2 lasers are not suitable for marking metals because the metal surface cannot effectively absorb their wavelength (≈10.6 µm). Only a small portion of the laser energy is absorbed, so laser ablation cannot occur on the metal surface.

The CO2 laser marking machine is a versatile and high-performance device designed for precise engraving, cutting, and marking of various non-metal materials. Utilizing advanced CO2 laser technology, it offers exceptional precision, wide material compatibility, and efficient operational performance, making it an ideal choice for creative design, industrial production, and small business applications.

Wide Material Compatibility

The CO2 laser marking & engraving machine can easily process a variety of non-metal materials, including wood, acrylic, leather, glass, fabric, paper, and more. Whether engraving intricate patterns or performing complex cuts, it can achieve tasks with extremely high precision, meeting diverse creative requirements.

High-Precision Engraving

Thanks to the advantages of CO2 laser technology, this engraving machine can create delicate lines and clear details on the material surface, ensuring that each piece reaches a professional level. Whether for text, patterns, or complex geometric designs, it delivers perfect results.

Efficient Cutting & Engraving

The machine supports high-speed engraving and cutting, capable of completing projects ranging from small crafts to large decorative pieces quickly. Its efficient performance significantly improves production efficiency, making it particularly suitable for batch production and custom requirements.

User-Friendly Design

The CO2 laser marker and engraver is simple and intuitive to operate, even for beginners. Its intelligent control system supports multiple file formats and features automatic focusing, ensuring optimal results with every operation.

CO2 Laser Marking & Engraving Machine Applications

Creative Design: Used for making personalized wooden crafts, acrylic decorations, leather engravings, and more, offering unlimited creative possibilities for artists and designers.

Industrial Production: Suitable for marking, cutting, and engraving tasks in mass production, such as processing packaging materials, textiles, and electronic components.

Educational Institutions: Provides practical teaching tools for schools and training institutions, helping students master the application of laser technology.

Small Business: Ideal for custom gifts, signage production, and small-scale manufacturing, helping entrepreneurs achieve efficient operations.

Infrared Picosecond Laser Marking Machine

The picosecond laser marking and cutting machine utilizes ultrashort pulse (picosecond-level) laser technology, characterized by high peak power and exceptional precision. Its key advantage lies in minimal thermal impact, enabling high-contrast black marking, color marking, and micron-level drilling and cutting on stainless steel, aluminum alloys, and other metals. With flexible operation, it is ideal for high-precision and high-quality processing needs and is widely used in industrial manufacturing, electronics, medical devices, and more.

- Ultrashort picosecond pulse laser with high peak power and an extremely small heat-affected zone, making it suitable for ultra-precise processing.

- Equipped with high-precision galvanometer and control system, ensuring micron-level positioning for intricate patterns and microstructures.

- Compatible with a wide range of materials, including metals, ceramics, glass and plastics, supporting black marking, color marking, and micro-hole processing.

- User-friendly interface, supporting multiple file formats and featuring automatic focusing and calibration for ease of use.

Applications:

- Black Marking on Stainless Steel & Aluminum Alloys: Achieves high-contrast black markings via laser oxidation, ideal for electronics, automotive components, and permanent identification.

- Color Marking on Stainless Steel: Creates vivid color engravings using laser interference effects, perfect for luxury goods, jewelry, and high-end decorative applications.

- Glass Cutting: Allows high-precision, smooth, and micro-crack-free cutting of thin and brittle glass materials, widely used in optical components, display panels, and precision manufacturing.

- Micron-Level Drilling & Cutting: Enables precise micro-hole drilling and fine cutting for semiconductors, precision electronic components, and high-accuracy applications, with no thermal damage.

UV Femtosecond Laser Micromachining Machine

The femtosecond laser marking machine utilizes ultrashort femtosecond pulse laser technology, delivering extremely high peak power with negligible thermal effects. Its core advantage lies in its ability to achieve high-precision glass cutting, drilling, and internal processing of transparent materials, making it ideal for micron-level engraving and marking. With exceptional stability, it is widely used in high-precision manufacturing fields such as optical components, microelectronics, and biomedical applications.

- Femtosecond-level ultrashort pulse laser marking with minimal thermal effect, ensuring high-precision and damage-free processing.

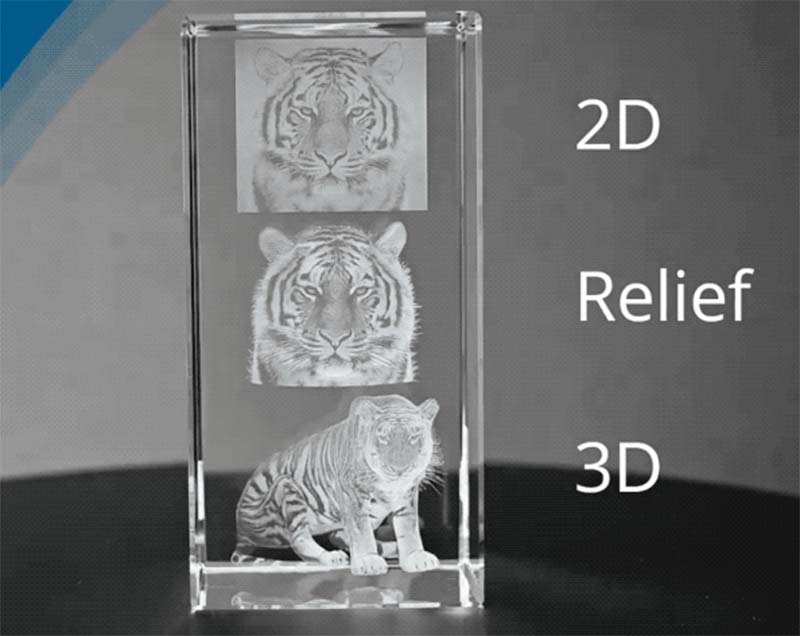

- Nanometer-level processing accuracy, perfect for glass cutting, micro-hole drilling, and transparent material internal engraving.

- Compatible with glass, metals, ceramics, and other materials, making it suitable for optical components, microelectronics, and advanced manufacturing.

- Intelligent control system with automatic focusing and calibration, ensuring ease of operation and improved efficiency.

- Energy-efficient design with low power consumption and long laser lifespan, making it cost-effective and environmentally friendly.

- Modular structure for easy maintenance and upgrades, offering industrial-grade durability for demanding environments.

Applications:

Glass Cutting & Drilling: Used for high-precision processing of smartphone screens, optical components, and other glass materials, ensuring smooth, damage-free edges.

High-Precision Micromachining: Ideal for micron-scale engraving and marking in microelectronics, photonics, and semiconductor applications.

Internal Processing of Transparent Materials: Enables precise modifications inside glass, sapphire, and other transparent materials, used for 3D optical components and data storage.

Picosecond vs. Femtosecond Laser Marking Machines

Both picosecond and femtosecond laser marking machines utilize ultrashort pulse technology, catering to high-precision processing across various materials and applications.

- Picosecond laser micro machining machines are ideal for black marking on metals, color marking, and micron-level machining, offering high contrast and precision with minimal heat effects.

- Femtosecond laser micromachining systems excel in glass cutting, internal processing of transparent materials, and ultra-fine structuring, ensuring damage-free and ultra-precise results.

Conclusion: these are the top laser marking machines for metal 2025. Laser engravers are the ideal choice for marking a wide range of materials, effortlessly handling both metals and non-metals. With exceptional precision and stable performance, these machines ensure you complete tasks with maximum efficiency while achieving high-quality results. For precise engraving needs, DPLASER ultrafast laser marking series stands out as the best choice, offering professional-grade technology and tailored solutions to meet your specific requirements. Click “Contact Us” and share your manufacturing requirements—we will provide you with a customized laser marking solution and the most competitive pricing.