With the laser welding industry advancing rapidly, manufacturers are focusing on machines that offer higher precision, better efficiency, and improved adaptability for modern production demands. The market in 2025 reflects these priorities, with several standout brands setting new benchmarks in technology and performance. To help users choose the right equipment for their specific needs, this article presents a comprehensive overview of the top 10 laser welding machine manufacturers.

Dapeng Laser specializes in multifunctional integrated laser welding equipment that combines welding, cutting, and cleaning capabilities, and supports a variety of metal materials. The equipment is lightweight in design, easy to operate, and highly intelligent, making it ideal for welding thin sheets (1–3 mm) of stainless steel, aluminum alloy, and more. It is widely used in industries such as kitchenware, decoration, and sheet metal processing.

As a leading enterprise in China’s laser industry, Han’s Laser is known for its high-precision and high-stability laser welding equipment, widely used in demanding fields such as automotive components, aerospace, and consumer electronics. Its fully automated welding solutions stand out particularly in terms of intelligence and system integration.

Typical applications: Automotive parts, precision aerospace components

HGTECH (Huagong Tech)

Leveraging its university research background, HGTECH focuses on integrating laser technology with intelligent manufacturing. Its laser welding equipment offers both reliability and cost-effectiveness, making it especially suitable for batch production needs of small and medium-sized enterprises. Application areas include machinery manufacturing, steel metallurgy, and electronic assembly.

Haiwei Laser

HaiweiLaser is widely favored among small and medium-sized enterprises for its advanced welding control systems and excellent stability. Its laser welding machines deliver high welding efficiency and strong adaptability, performing exceptionally well in the welding of complex parts. These machines can easily handle various types of workpieces and offer great cost-performance, making them ideal for enterprises focused on practicality and cost control.

MAX

As a well-known domestic laser source manufacturer, MAX has gradually expanded into the complete machine equipment sector in recent years. Its laser welding products excel in performance stability, beam quality, and power output. They are widely used in power battery manufacturing, sheet metal processing, and intelligent manufacturing, forming a vital part of industrial-grade laser solutions.

Huaray Laser

Huaray Laser’s “Red Tong Series” features a lightweight design and intelligent system optimization, resulting in the K1M handheld laser welding machine weighing only 3.8 kg, significantly reducing operator fatigue during long periods of use. Its smart air-cooling system runs at a noise level as low as 65 dB, and achieves surface quality of Ra ≤ 0.8 μm in stainless steel kitchenware welding, greatly reducing the need for post-processing. Moreover, the 10-meter flexible fiber transmission technology is suitable for large components, and in shipbuilding scenarios, its daily welding efficiency has exceeded traditional methods by more than three times—demonstrating outstanding on-site adaptability

IPG

IPG is a globally renowned manufacturer of fiber lasers. Its laser welding equipment is trusted worldwide for its high efficiency, excellent reliability, and superior beam quality. The products are widely used in industries with extremely high welding quality requirements, such as electric vehicle batteries, precision electronics, and medical devices.

Rofin

Rofin focuses on high-end precision laser welding solutions. Its equipment offers outstanding welding consistency and process stability, making it particularly suitable for niche sectors such as microelectronics, medical devices, and precision modules. Its level of automation and intelligence makes it ideal for integration into advanced manufacturing lines.

TRUMPF

TRUMPF is a global leader in industrial laser solutions. Its laser welding machines are known for outstanding beam quality, extremely high welding precision, and excellent system stability. The equipment is widely applied in demanding industries such as automotive manufacturing, precision machinery, and medical device production.

Bodor Laser

Bodor Laser has shown strong performance in the laser cutting equipment market in recent years and is now rapidly emerging in the laser welding field. Its welding equipment integrates an intelligent operating system, automated controls, and multiple safety protection features, offering both user-friendliness and industrial-grade performance. It is suitable for applications in sheet metal processing, kitchen and bathroom manufacturing, and advertising decoration.

Brands like Han’s Laser, HGTECH, DPLASER and IPG enjoy strong recognition and significant market share both domestically and internationally. Their laser welding equipment is widely trusted for its outstanding performance and broad applicability, making them reliable laser welding machine 2025. As for the question, “Which laser welding machine brand is the best?” — There is no the answer. The key lies in selecting a laser machine that aligns with your specific process requirements, budget, and application needs.

Global Laser Welding Machine Market in 2025

Among the brands of top 10 laser welding machine 2025, fiber laser welding machines are seeing a significant rise in both market share and technological attention. It is projected that by 2025, the global market size for fiber laser welding equipment will exceed USD 8 billion, with a compound annual growth rate (CAGR) of 12%, highlighting strong momentum and promising development prospects.

Technological Advancements

The core advantage of fiber laser welding machines lies in their laser source technology. Fiber lasers offer high electro-optical conversion efficiency (exceeding 30%) and excellent beam quality (M² < 1.05), enabling an ideal balance between micron-level precision and high-speed welding.

Compared to traditional CO₂ lasers, fiber laser welding machines eliminate the need for complex gas circulation systems, resulting in 40% smaller equipment size, 60% lower maintenance costs, and greater tolerance to challenging environments such as humidity and dust.

For example, in automotive battery tray welding, fiber laser machines can increase the welding yield rate of dissimilar copper-aluminum metals to 99.8%, while keeping thermal deformation within 0.1 mm—a critical factor for the structural integrity of lightweight metal assemblies.

Cost Advantages

Currently, mainstream fiber laser welding machines are 30%–50% less expensive than CO₂ lasers of equivalent power. Operating costs—including electricity and consumables—are only about one-third of those for CO₂ systems. For small and medium-sized enterprises, these cost benefits significantly lower the barrier to automation and intelligent upgrades.

Cross-Industry Demand

In lithium battery PACK production lines, fiber laser welding machines have become indispensable for welding highly reflective materials such as copper and aluminum, especially in tasks like cell tab welding and module sealing. A single machine can replace 5–8 workers and increase production speed to 1.2 meters per minute.

In the consumer electronics industry, the growing demand for precision welding of miniature components—such as foldable screen hinges and micro-sensors—is driving the evolution of fiber lasers toward short-pulse and ultrafast laser technologies.

Intelligent and Flexible Manufacturing

By integrating vision-based positioning systems and real-time feedback modules, fiber laser welding machines can automatically detect workpiece deviations and dynamically adjust welding paths. This capability makes them ideal for flexible manufacturing environments involving multi-variety, small-batch production.

The Best Fiber Laser Welding Machine 2025

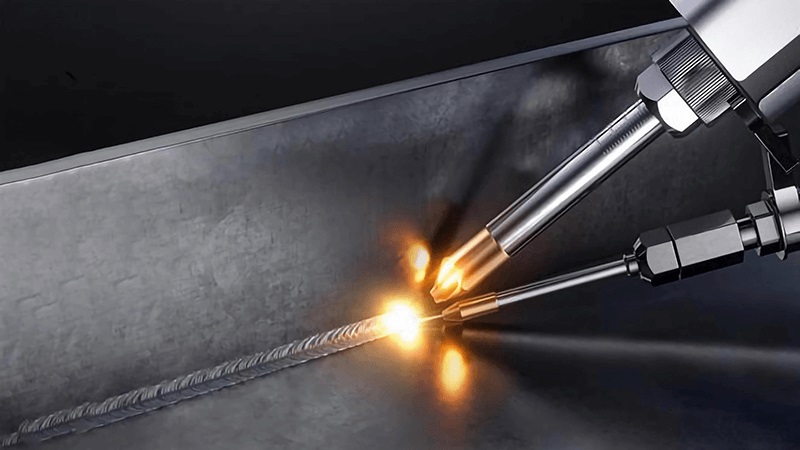

All-in-One Handheld Laser Welding Machine

This 3-in-1 handheld laser welding machine integrates welding, cutting, and cleaning functions into a single device. It is widely used for efficient welding tasks on 1–3mm metal sheets. With simple operation and a high degree of automation, it is especially suitable for batch work in light industries such as kitchenware, sheet metal, and advertising decoration. It can be paired with 4-in-1 or 5-in-1 welding systems to meet more advanced processing needs.

Price range: Approximately $3,000 – $8,000 USD

Wide Application Range

Supports welding of 1–3mm thin metal sheets. Power ranges from 1000W to 3000W, compatible with materials like stainless steel, aluminum alloy, and carbon steel.

3-in-1 Functionality

Combines welding, cutting, and cleaning. Built-in with 8 intelligent process modes, greatly enhancing the machine’s versatility.

Deep Penetration Welding Capability

At full power, it can achieve a welding depth of up to 8mm with smooth, spatter-free weld seams, reducing the need for post-weld grinding and cleaning.

Lightweight Design

The welding gun weighs only 0.6kg and is ergonomically designed to reduce operator fatigue during long periods of use, making it ideal for batch welding applications.

Smart Control System

User-friendly interface with process memory functionality, lowering the learning curve for operators.

Typical Application Scenarios

Light industries such as kitchen and bathroom equipment, stainless steel processing, sign making, and door and window decoration.

Portable Air-Cooled Handheld Laser Welding Machine

This portable handheld laser welding machine features a brand-new air-cooled structural design, with a total weight of under 30kg, making it easy for a single person to carry. Specifically engineered for mobile on-site welding applications, it offers remote control, intelligent temperature regulation, and precise parameter matching—making it a highly integrated and portable laser welding solution.

Price range: Approximately $2,000 – $3,000 USD

Lightweight & Portable

Weighs less than 28kg, allowing for single-person operation and transport. Ideal for outdoor work or confined spaces.

Integrated Welding Gun Design

The welding gun weighs only 530g. The laser path, focusing lens group, and gun body are seamlessly integrated for more flexible and convenient operation.

Upgraded Wire Feeding System

Equipped with dual-drive motors and a fully enclosed design, it supports 20kg wire feeding capacity. Smooth feeding improves welding efficiency and quality.

Intelligent Temperature Control System

Combines high-performance copper tube arrays, stacked cooling fins, and a low-noise fan with intelligent algorithms to ensure stable laser output.

Precision Process Matching

Enables sheet thickness selection with 0.1mm accuracy and offers a rich library of adjustable parameters for highly consistent welding results.

Remote Control Support

Includes app connectivity and remote-control features for diagnostics, parameter adjustments, and online system upgrades.

Automatic Laser Welding Machine

This automatic fiber laser welding machine integrates a high-precision fiber laser source with an advanced automation control system, making it ideal for continuous, high-volume production environments. With a multi-axis motion platform and optional vision recognition system, it enables complex path welding and high-speed operation—an excellent solution for manufacturers aiming to boost welding automation efficiency.

Price range: Approximately $10,000 – $30,000 USD (depending on multi-axis and system configuration)

Intelligent Control System

Supports PLC and HMI operation with automatic process parameter retrieval, ensuring consistent welding quality.

High-Precision Path Control

Equipped with CNC or multi-axis motion platforms to perform complex weld trajectories at high speeds.

Wide Material Compatibility

Supports carbon steel, stainless steel, aluminum alloy, and more. Ideal for batch welding of 3C products, battery casings, metal components, etc.

Stable Laser Output

Optional fiber laser source delivers high stability and low maintenance, suitable for continuous operation.

Optional Vision Recognition Support

Integrates industrial cameras for precise positioning and weld seam tracking, significantly improving yield rates.

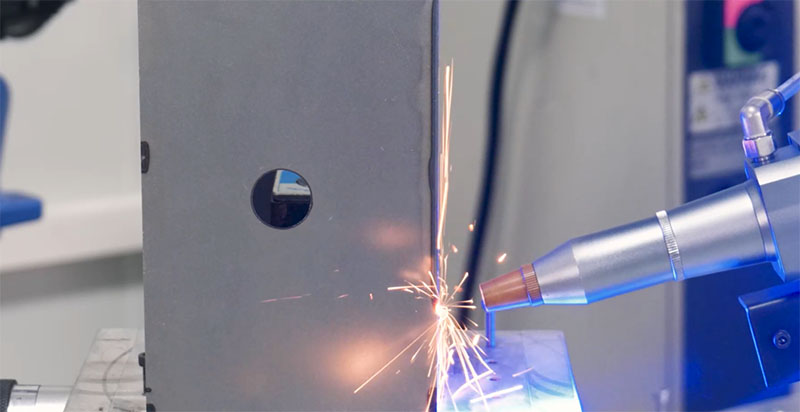

Collaborative Robot Laser Welding Machine

The cobot laser welding system deeply integrates flexible laser welding technology with intelligent collaborative robots. Featuring a lightweight design, high safety, and easy deployment, it is ideal for small-batch, multi-variety customized production. It is especially suitable for automation upgrades in industries such as sheet metal fabrication, control cabinets, and electrical enclosures.

Price range: Approximately $20,000 – $40,000 USD (depending on the robot model and supporting systems)

Flexible Deployment

The collaborative robot supports multi-angle arm movement and flexible path planning, adapting to welding of non-standard structural parts.

Fence-Free Safety Design

Built-in collision detection and force control system ensure safe operation in human-robot collaborative environments.

Easy Programming

Intuitive graphical interface with support for teach mode and automatic path learning significantly reduces the learning curve.

High-Performance Fiber Laser

Ensures consistent welding depth and stable laser beam quality, resulting in clean welds with minimal deformation.

Wide Application Scenarios

Ideal for flexible production lines, mechanical parts, and prototyping stages.

Highly Expandable

Can be integrated with wire feeders, rotary tables, and vision positioning systems to achieve fully automated welding processes.

The above laser welding machines cover a wide range of needs—from portable handheld units and automated production systems to collaborative robot applications—offering high performance, intelligence, and flexibility to meet welding upgrade demands across various industries and scenarios. Whether for lightweight, mobile operations or high-precision, high-efficiency batch production, these machines represent the cutting edge of modern laser welding technology. Combined with excellent performance and a competitive best laser welding machine price, they provide manufacturers with highly cost-effective welding solutions, helping to improve production efficiency, product quality, and drive the transformation toward smart manufacturing.