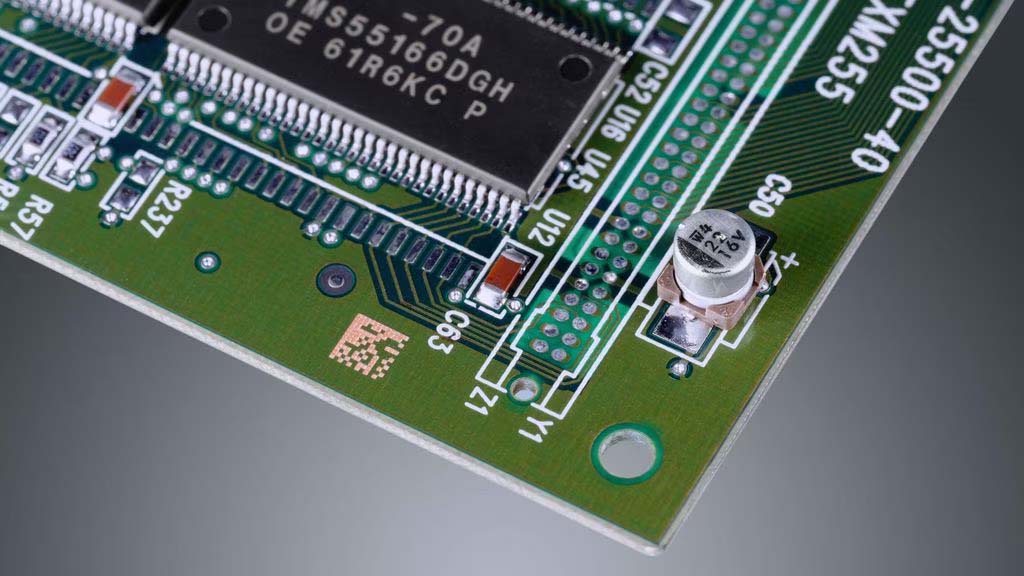

PCB circuit boards (circuit boards) are key components and connection carriers in the 3C industry. With the development of intelligent electronics industry, the number of electronic components has increased, and the requirements for precision processing have also increased. Laser marking printed circuit board are used in the PCB industry to mark traceable information such as barcodes, QR codes, characters and graphics on circuit boards, helping to achieve automated and intelligent management and meet the needs of lean production, quality control and process improvement.

Printed circuit boards are one of the most important parts of electronic components, and the production requirements of PCBs are very strict and do not allow errors. The high accuracy and flexible operation of laser marking machine can perfectly meet any need for marking process in circuit board manufacturing

How PCB Laser Marking Machine Works?

Laser marking uses a high-energy-density laser beam to locally heat an object, causing its surface material to instantly melt or vaporize, creating a permanent mark. This marking method can produce text, patterns, barcodes, QR codes, and other information.

A PCB laser marking machine primarily consists of five parts: the laser source, galvanometer scanner, control system, workpiece fixing device, and computer control software.

Laser Source: The laser source is the core component of the equipment, responsible for generating the high-energy-density laser beam. During the PCB laser marking process, the laser beam is focused on a very small area, rapidly increasing the temperature in that region, causing the metal or plastic surface on the circuit board to melt or vaporize, and forming a permanent mark. Different types of lasers can be used, such as CO2 lasers, fiber lasers, or UV lasers, depending on the material and application requirements.

Galvanometer Scanner: This device controls the direction of the laser beam. It consists of two mirrors driven by high-speed motors that can quickly and accurately direct the laser beam to the desired location on the PCB.

Control System: The control system manages the direction, power, and pulse width of the laser beam to ensure the precision and efficiency of the marking. Additionally, the control system can be remotely adjusted and monitored via computer software, significantly enhancing the equipment’s operational flexibility.

Worktable: The platform where the PCB is placed for marking. It may include fixtures or clamps to hold the PCB in place during the marking process.

The computer control software serves as the operating interface for the entire equipment, allowing users to set marking parameters, design marking patterns, manage the equipment, and view printing results.

The Application of Laser Marking Machine for PCB

In the electronics industry, Laser PCB marking system can be used in circuit board manufacturing, electronic component assembly and so on. On the circuit board, various components such as resistors, capacitors, chips, etc. need to be marked for identification in the subsequent production, testing and repair process. Laser marking PCB, can directly print clear markings on the surface of components, such as model, specification, production date and other information, which improves production efficiency and product quality. In addition, it can also be used for medical equipment, automotive parts and so on.

The Advantages of Laser Marking in the PCB Industry

- Efficiency: The fully automatic PCB laser marking machine boasts high production efficiency. Its rapid marking speed allows it to complete a large number of marking tasks in a short time. Additionally, the machine’s high degree of automation and ease of operation significantly reduce labor costs and enhance production efficiency.

- Precision: Thanks to the high energy density of the laser beam, the machine can achieve extremely fine markings, resulting in high-quality engraving effects with clear and aesthetically pleasing text or patterns.

- High Readability: Utilizing a digital printing method, the markings are clear, easy to read, and resistant to wear.

- Wide Adaptability: The laser marking machine offers a choice of fiber lasers, CO2 lasers, or UV lasers, making it suitable for different types of PCB materials. Additionally, laser marking can produce a variety of colors and patterns, providing more options for PCB identification.

- Non-Contact Process: Laser engraving is a non-contact process, which means it does not cause mechanical damage or stress to the PCB.

- High Flexibility: The laser marking parameters can be adjusted according to different requirements, enabling personalized customization.

The patterns are the core components of a circuit board, and their quality and precision are directly related to the performance of the board. Laser marking machines can print fine lines and text on circuit patterns, ensuring PCB identification and traceability. Moreover, the high precision of laser marking guarantees the accuracy and stability of the circuit patterns, thereby improving the reliability and stability of the circuit board.

How to Choose a Laser Engraver for PCB?

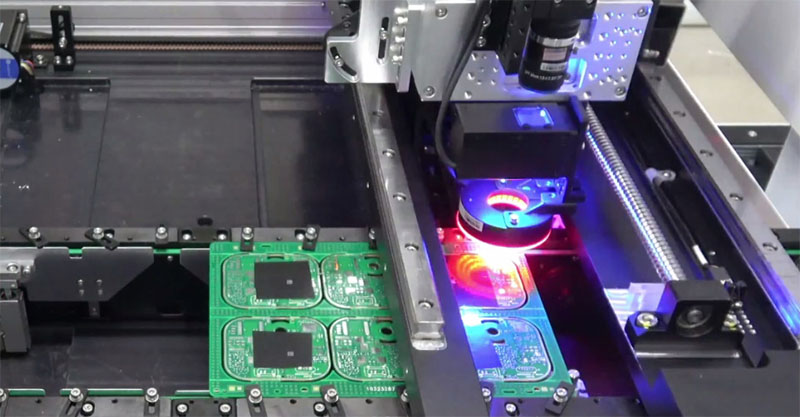

The PCB Automatic Laser Marking Machine, independently developed by Dapeng Laser, is a highly automated marking device specifically designed to meet the online laser engraving needs of PCBs (Printed Circuit Boards). This equipment integrates advanced laser technology with automated control, enabling high-precision and high-efficiency engraving on PCB boards. Laser marking is widely used for branding, traceability, and identification of components, making it the preferred solution for adding information to electronic parts, PCBs and components.

- PCB laser marking system high-performance laser, good engraving quality, high-precision CCD, can docking customer MES system data information.

- According to the customer PCB marking requirements and specific needs, three kinds of optical paths are available: UV laser, fiber laser and CO2 laser.

- Engrave barcode, QR code, and logo, manufacturing date, batch number, expiry date and other texts, can connect with customer production line for online production, and can be configured with loading and unloading machine for offline production.

- High-precision CCD for automatic positioning, automatic verification of the engraved code by barcode gun reading.

- Seamless connection with mature SMT lines.

- Easily connect with customer MES system for online data transmission and information return.

- Compared with the ordinary printing method, no consumables, environmental protection and pollution-free, maintenance-free.

In the production of PCB, this online automatic laser marking machine can achieve continuous, automated laser engraving operations. Through the preset laser engraving pattern or text, the equipment can automatically carry out accurate laser engraving on the PCB board without human intervention. This not only greatly improves production efficiency, but also reduces labor costs and improves product quality and consistency.

PCB

Printed Circuit Board Laser Marking: we provide permanent, solder-resistant and machine-readable markings for printed circuit boards. This helps to ensure flawless quality, correct identification and complete traceability throughout the product lifecycle. Typical markings on PCBs include alphanumeric characters, complex 2D data matrix codes and customized content.

Displays

Laser marking machines are widely used in the production of displays to ensure traceability and market access standards for every display by providing permanent and high contrast markings for serial numbers, batch numbers, brand logos, trademarks and various certification marks.

Electronics Housings

On the shell of electronic products, laser marking technology can accurately engrave product information, model number, company Logo, brand name, anti-counterfeiting mark and QR code, which not only enhances the appearance quality and brand value of the product, but also strengthens the security of anti-counterfeiting and ensures the accuracy and traceability of the information.

DPLASER specializes in creating affordable PCB laser marking machine price, designed to meet your specific production needs. Simply share your production line requirements and our team of experts will craft a personalized laser marking solution that seamlessly integrates into your manufacturing process, improving efficiency while reducing costs. From consultation to implementation, DP Laser is committed to focusing on customer needs to create efficient and accurate PCB marking solutions to help companies upgrade their competitiveness.

Flexible circuit boards offer high wiring density, lightweight design, thin profile, flexibility, and 3D assembly capabilities. As the industry rapidly evolves, the processing technology for flexible circuit boards is also continuously innovating. In the electronics industry, most manufacturing processes rely heavily on laser processing applications. Dapeng Laser provides advanced laser processing technologies, including laser marking, laser welding, laser cutting, laser drilling, laser etching, and laser forming, which are widely used in electronic manufacturing.