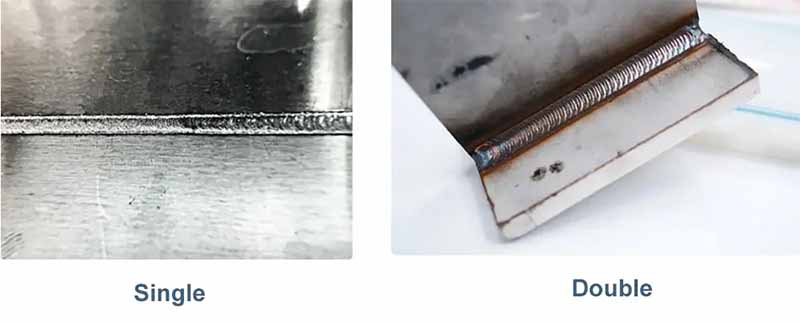

The choice between single swing and double swing welding systems plays a critical role in determining weld quality, precision, and adaptability. These two configurations refer to the motion control of the galvanometer scanner in the welding head. While single swing welding utilizes one-axis oscillation to stabilize the weld pool, double swing welding adds an additional axis, enabling more complex and stable welding paths. This results in better weld strength, smoother seams, and broader application adaptability. Understanding the difference between single swing & double swing welding is essential for choosing the right solution for your production needs.

Why is a Galvanometer Motor Required for Laser Welding?

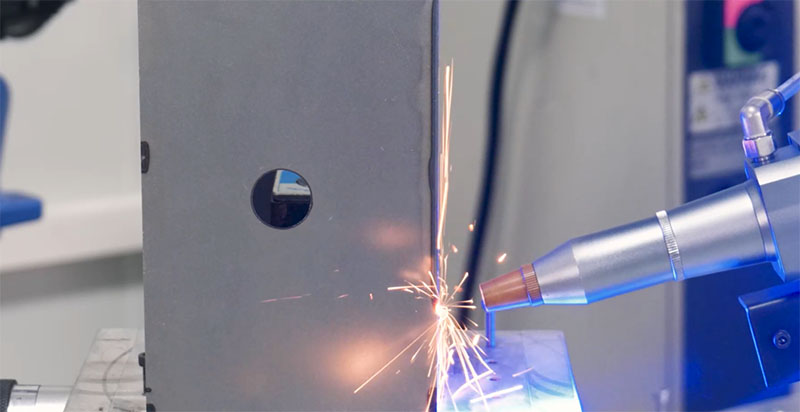

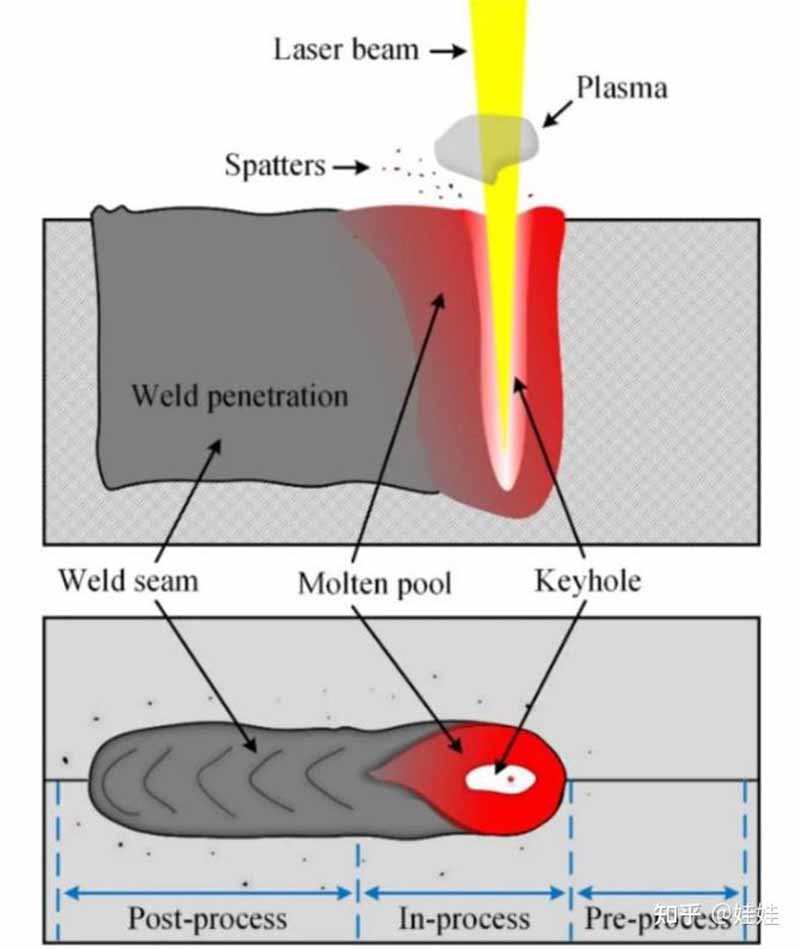

During laser welding, a focused laser beam is directed onto the surface of the material, rapidly heating and melting it to form a molten pool. As the process continues, the two materials are fused together within this molten pool. Under coaxial gas shielding, the weld cools quickly, completing the welding process. In this fusion and cooling stage, the materials melt into each other and bond thoroughly.

For narrow weld seams (approximately 0.1 mm), the molten pool allows the materials to merge naturally due to their own fluidity. In such cases, a non-oscillating galvanometer welding head can be used, as the small weld path ensures good fusion. However, for wider weld seams (greater than 0.1 mm), issues such as porosity, pits, and cracks may arise if no oscillation is applied during welding. Oscillation helps expand the molten pool and improve the quality of fusion, thereby minimizing welding defects.

There are two types of oscillation modes in galvanometer-based laser welding:

- Single-pendulum: The laser beam oscillates in one direction (typically X or Y axis), controlled by a single galvanometer motor.

- Dual-pendulum: Two galvanometer motors control the beam in both X and Y directions, allowing for more complex oscillation patterns and a wider range of welding applications.

In handheld laser welding, embedded controllers are commonly used as the control system. Depending on whether the galvanometer uses a single or dual-axis motor for beam steering, handheld laser welding systems are categorized into single-axis control systems and dual-axis control systems.

Single Pendulum VS Double Pendulum Welding

Single-Pendulum Welding System

The single swing laser welder features a simple structure, easy operation, and lower equipment cost, making it widely used in conventional sheet metal processing. However, it has a limited oscillation angle and lower directional control precision, which restricts its effectiveness in more complex welding scenarios.

Double-Pendulum Laser Welding System

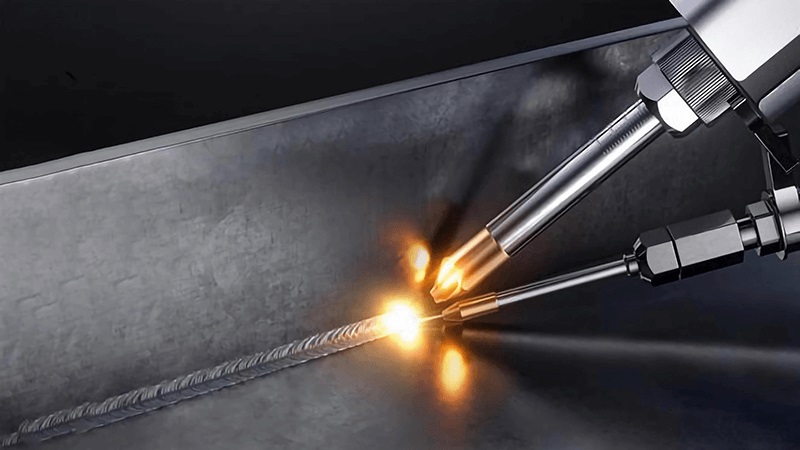

In contrast, the double swing laser welding machine enables flexible beam steering through two-axis oscillation, significantly enhancing welding flexibility and efficiency. This system excels in handling wide gaps, dissimilar materials, and complex structures, delivering higher-quality welds. Due to its more complex design—featuring two galvanometer motors and dual mirrors—the cost is comparatively higher.

Precision

The dual-pendulum welding system allows for dynamic adjustment of the laser beam angle. Even in situations involving sharp angles or hard-to-reach areas where direct laser incidence is not possible, the system can adapt to maintain welding accuracy. This dramatically reduces reliance on manual alignment, making it ideal for tasks that involve intricate geometries, high precision, or frequent path changes—one of its key advantages over single-pendulum systems.

Performance Superiority of Double Pendulum

With more precise control over laser energy and heat input, the double-pendulum system ensures better weld consistency and seam formation. It shows particular advantages when welding thin-walled materials or dissimilar metals. Field data indicates that double-pendulum welding improves qualification rates by approximately 15% compared to single-pendulum systems. The resulting welds are smooth and uniform, often requiring little to no post-processing.

Limitations of Single Pendulum

Single-pendulum systems struggle with complex welding paths or thin sheets that are sensitive to heat input. Common issues include burn-through and weld deformation, making it difficult to meet high-quality welding standards—especially in applications requiring high precision.

Cost

- Double Pendulum: Although the initial investment is higher, the system offers better productivity, lower energy consumption, and reduced rework rates. Over time, this translates into greater cost-effectiveness, making it the preferred choice for quality- and performance-oriented manufacturers.

- Single Pendulum: The lower upfront cost makes it suitable for startups or factories with limited budgets. However, its lower efficiency and higher error rates can lead to increased operating costs over time, potentially outweighing the initial savings.

Application Scenarios

- Single Pendulum: Best suited for straight-line or simple curved welds, such as in furniture, kitchenware, and general sheet metal fabrication.

- Double Pendulum: Ideal for welding complex geometries, wide-gap joints, or high-precision components where flexibility and quality are critical.

Single Swing & Double Swing Handheld Laser Welding Control System

1. Laser Control

The single-pendulum handheld laser welding system provides precise control over laser parameters such as power, beam size, and oscillation angle. These adjustable settings allow the system to accommodate a wide range of welding tasks and material types.

2. Parameter Configuration

Operators can quickly adjust the system to an optimal working state by setting predefined parameters. For example, power levels can be adapted with one-click presets for different metals, or beam dimensions can be rapidly adjusted to suit various weld seam widths—enhancing operational efficiency and repeatability.

3. Information Display

The system features a user-friendly display interface that presents key operational data in real time. Critical information such as welding status, processing time, and system performance is clearly shown, enabling operators to monitor and evaluate the welding process effectively.

4. Safety Alarms and Diagnostics

Equipped with real-time monitoring and diagnostic capabilities, the system continuously supervises laser emission, beam alignment, cooling performance, and more. In the event of a fault or abnormal condition, it promptly issues warnings and diagnostic feedback to ensure safe and stable operation.

How to Choose the Single Pendulum and Double Pendulum Handheld Laser Welding Machine

When selecting a single-pendulum or double-pendulum handheld laser welding system, it is essential to evaluate the following key factors:

1. Welding Requirements

Consider the specific welding tasks—such as seam shape, gap width, and material type.

For narrow, simple welds on standard sheet metal, a single-pendulum system is typically sufficient.

For wide gaps, dissimilar materials, or complex geometries, a double-pendulum system offers superior control and weld quality.

2. Budget Considerations

Double-pendulum systems are more technologically advanced and generally come at a higher price.

If operating under a limited budget, a single-pendulum system may be a more cost-effective choice—though it may involve trade-offs in performance and versatility.

3. Ease of Operation

Single-pendulum systems are usually easier for beginners or non-specialist operators to learn and use.

However, with modern user interfaces and improved training support, double-pendulum systems are becoming increasingly user-friendly and accessible, even for less experienced personnel.

| Type | Single pendulum | Double pendulum |

| Applicability | Simple & repetitive welding tasks; low requirements on penetration depth and strength. | Complex parts, non-standard shapes; welding of dissimilar materials, especially highly reflective materials such as aluminum and copper. |

| Efficiency | Medium efficiency | Efficient and more suitable for complex shapes |

| Technical skills | low requirements, easy operation | Senior and experienced welders are needed |

| Cost | low equipment price and maintenance costs | The equipment structure is more complex and the cost is higher |

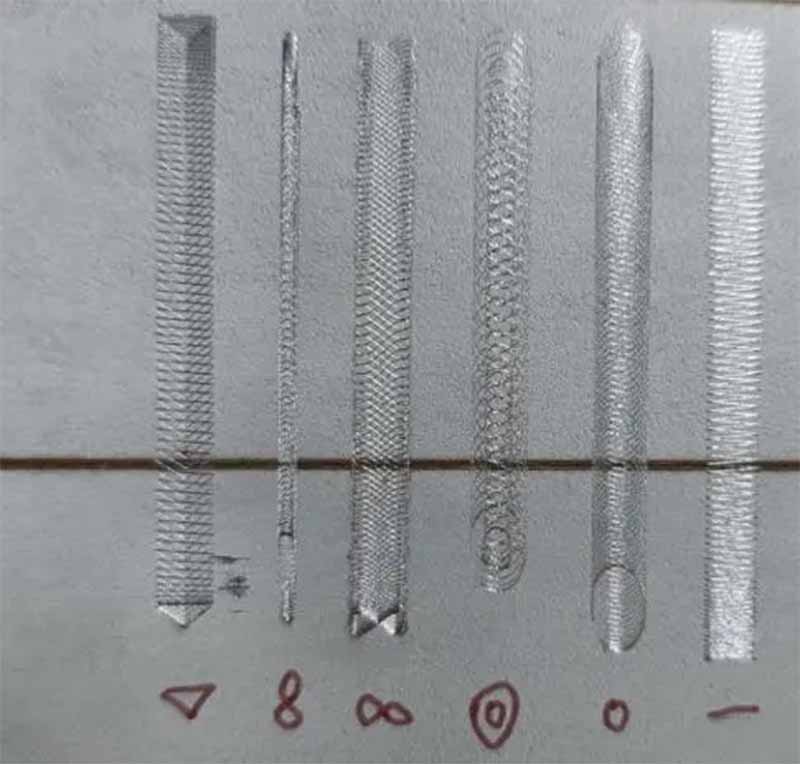

Six Typical Double-Swing Laser Welding Modes

Using double-swing laser welding is highly advantageous. The machine offers six distinct swinging modes to suit various welding needs:

- Linear Swing: Enhances weld penetration and seam uniformity, ideal for improving stability in standard welds.

- Circular Swing: Suitable for small round components or curved weld paths, providing consistent energy distribution along circular geometries.

- Figure-8 Swing: Ideal for deep penetration welding or dynamic heat control, ensuring stable molten pool behavior and reducing thermal stress.

- Double-Arc Swing: Enhances fusion on both sides of the seam, especially useful for wider joints or dissimilar thickness connections.

- Triangle Swing: Optimized for beveled edges or angled joints, facilitating smooth material bridging across varying seam profiles.

- Double-Triangle Swing: Best suited for irregular or offset seams, offering precise control of heat input across non-uniform welding paths.

3 in 1 Double Pendulum Handheld Fiber Laser Welding Machine

The Dapeng Laser 3-in-1 Double Pendulum Handheld Fiber Laser Welding Machine integrates welding, cutting, and cleaning functions into one unit. It is widely applicable for the efficient processing of various metal materials such as carbon steel, stainless steel, aluminum, and titanium.

Equipped with an advanced dual-pendulum welding head, the machine delivers aesthetically pleasing weld seams and high welding stability, adapting well to various complex working conditions. Depending on the power configuration:

The 1500W model supports welding thicknesses from 0.3mm to 4mm

The 2000W model handles 0.3mm to 6mm

The 3000W version can weld up to 7.5mm thick

For handheld cutting, it supports thicknesses up to approximately 3mm, meeting the processing needs of medium and thin plates, as well as some thicker materials.

The 3 in 1 laser welding machine also supports optional configurations of single or dual wire feeders, offering flexibility to accommodate different welding processes. It is ideal for a wide range of applications including sheet metal fabrication, hardware manufacturing, machinery maintenance, and component production. This is a highly efficient, cost-effective, and multifunctional laser welding solution.

3-in-1 Double Pendulum Welding Gun

The portable handheld welding head supports dual or single wire feeding. With its compact and ergonomic design, it replaces fixed welding heads and provides great convenience for welding large, heavy, or structurally complex items.

Laser Welding System

The laser welding system features a user-friendly interface with a touchscreen and powerful software functions. It supports the use of a preset process library and allows editing and storage of welding parameters for workpieces, effectively optimizing the welding process and ensuring weld quality and forming results.

Fiber Laser Source

The core laser source adopts the globally renowned Raycus fiber laser, offering high photoelectric conversion efficiency and enhanced laser power. This significantly improves welding performance and supports flexible configuration based on customer needs. Global warranty service is included to ensure stable operation and reduce maintenance costs.

S&A Industrial Chiller

The cooling system uses an S&A industrial chiller, which provides stable cooling performance and easy operation. It uses environmentally friendly refrigerants to ensure long-term, efficient equipment operation.

Dual Wire Feeding System

The dual wire feeding system operates automatically and is compatible with 0.8mm, 1.0mm, 1.2mm, and 1.6mm wires. Feeding speed is adjustable to meet various welding strength and precision requirements, enhancing welding performance.

Laser Welding Nozzles

A full set of laser welding nozzles is included, suitable for various welding, cutting, and cleaning applications. They support a range of specifications and models to meet different process requirements, enabling flexible application in diversified laser processing tasks and ensuring welding quality and processing efficiency.

Optional Components

The equipment also supports customized configurations, with optional Raycus or MAX brand laser sources and flexible power selections. It is compatible with the 4-in-1 SUP23T welding head and the 5-in-1 laser welding system, further expanding processing functions and application scenarios.

This all in one double pendulum fiber laser welding machine is suitable for the efficient welding of a wide range of metals and their alloys, including stainless steel, copper, aluminum, gold, chromium, silver, and more. It also supports dissimilar metal welding, such as copper to brass and nickel to copper, ensuring strong welds with smooth and aesthetically pleasing finishes.

It is widely used across various industries, including kitchen cabinets, staircases and elevators, shelving, ovens, stainless steel doors and window railings, handicrafts, and home decoration. It meets diverse welding process requirements with high adaptability and performance.

In conclusion, selecting the right welding configuration is essential for achieving high-quality, consistent results in industrial applications. A double swing laser welding machine offers enhanced stability, deeper penetration, and superior weld appearance compared to single swing systems, making it an ideal choice for complex and demanding welding tasks. With its advanced control, precise motion, and broader application range, it provides manufacturers with a powerful tool to improve welding efficiency and reliability. For those seeking higher standards in metal joining, double swing technology represents the next step forward in laser welding innovation.